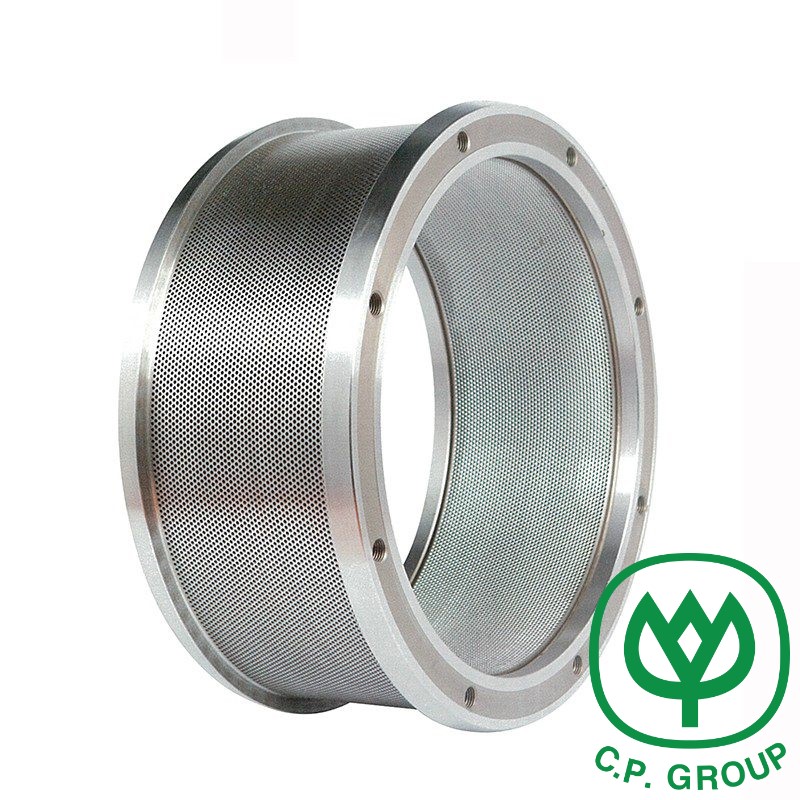

I-SZLH yochungechunge lwe-pellet mill ring iyafa

- SHH.ZHENGYI

1.Khetha izinto zokusetshenziswa zekhwalithi ephezulu, ukwenza insimbi yesibili, i-billet yokukhipha igesi;

2.Impahla yokufa yendandatho: X46Cr13 / 4Cr13 (insimbi engagqwali), 42Crmo / 20CrMnTi (insimbi yengxubevange) noma ezinye izinto ezenziwe ngokwezifiso;

3.I-imported gun drill kanye ne-multi-station drill, imbobo yokufa ngesikhathi esisodwa, ukuqedwa kwekhwalithi ephezulu, ukukhiqizwa kokuphakelayo, ukubukeka okuhle nokuphuma okuphezulu;

4.Khetha inhlanganisela yesithando somlilo kanye nesithando somlilo esiqhubekayo ukuze uqinisekise impilo ende yesevisi;

5.Ngokwesimiso kanye nezidingo zekhasimende ukuklama isilinganiso sokucindezela namandla;

6.Ukuhlolwa kwe-Microscopic ukuqinisekisa ikhwalithi yomkhiqizo;

Ubuchwepheshe bokucubungula indandatho yensimbi ye-42Crmo / 20CrMnTi:

Ukusika→Ukufomatha→Ukujwayela→Ukugwedla→Ukushisa→Ukuqeda→Ukubhoboza (Ukunweba) Imbobo→Ukungcwaba→Ukugaya→(Ngaphandle Kwesendlalelo Se-oxidation) →Ukuhlola Ukucindezela→(I-Phosphorus Passivation)→Ukumboza Amafutha Angavimbeli →Hlola bese ulondoloza izinketho;

I-X46Cr13 / 4Cr13 ubuchwepheshe bokucubungula indandatho yensimbi engenasici:

Ukusika→Ukufoshela→Ukugwedla→Ukujwayela→Ukuqeda→Ukucisha nokushisa→Ukuqeda→Imbobo yokubhoboza→I-Nitriding→Ukupholisha→Ukuhlola ukucindezela→Ukumelana nokumboza→Uwoyela ogqwalile→Hlola bese ulondoloza izinketho;

| I-S/N | Imodeli | Usayizi OD*ID*ububanzi bonke*ububanzi bephedi -mm | Usayizi wembobo mm |

| 1 | I-SZLH320 | 432*320*130*87 | 1-12 |

| 2 | I-SZLH350 | 500*350*180*100 | 1-12 |

| 3 | I-SZLH400 | 558*400*200*120 | 1-12 |

| 4 | I-SZLH400D | 558*400*218*138 | 1-12 |

| 5 | I-SZLH420 | 580*420*196*120 | 1-12 |

| 6 | I-SZLH420D | 580*420*214*140 | 1-12 |

| 7 | I-SZLH508 | 660*508*238*155 | 1-12 |

| 8 | I-SZLH508E | 660*508*284*185 | 1-12 |

| 9 | I-SZLH558 | 774*572*270*170 | 1-12 |

| 10 | I-SZLH578 | 774*572*300*200 | 1-12 |

| 11 | I-SZLH768 | 966*761*370*210 | 1-12 |

Igobolondo le-roller elinyathele

Igobolondo le-roller lingenye yezingxenye eziyinhloko zokusebenza ze-pellet mill. Isetshenziselwa ukucubungula ama-pellets ahlukahlukene e-biofuel, ukudla kwezilwane namanye ama-pellets. Isebenzisa i-alloy steel eqinile engagugi (40Cr, 20Crmnti, Gcr15), ukwelashwa kokushisa kwe-carburizing, ubulukhuni obufanayo. Impilo yesevisi yinde, futhi kunezinhlobo ezahlukene zezakhiwo ezifana nokumise okwezinyo, okuvimbekile okumise okwezinyo, nokumise okwembobo. Ingxenye ye-roller ecindezelayo yenziwe nge-eccentric shaft yangaphakathi nezinye izingxenye ezinobukhulu obunembile, okulula ukulungisa ibanga phakathi kwe-roller ecindezelayo kanye nokufa kwendandatho ngokuya ngezidingo zokukhiqiza komsebenzisi, futhi kulula ukugoqa nokuyifaka, futhi kulula ukufaka esikhundleni igobolondo roller ngokucindezela.

Izinyathelo zokuzivikela:

1. Khetha kahle isilinganiso esifanele sokucindezelwa kwembobo yokufa;

2. Lungisa kahle igebe elisebenzayo phakathi kweringi kanye nerola yokucindezela ukuze libe phakathi kuka-0.1 no-0.3mm (i-rola yokucindezela ishayelwa ukufa kweringi ngemva kokuba i-granulator entsha ivulwe esimweni “esifana nokuzungeza kodwa esingazungezi”) ;

3. I-ring entsha kufanele isetshenziswe ne-rola yokucindezela entsha, futhi i-pressure roller kanye ne-ring die kufanele ikhululeke ngaphambili bese iqiniswa. Uma amakhona abukhali avela ezinhlangothini zombili ze-roller yokucindezela, i-flange ye-roller yokucindezela kufanele ihanjiswe nge-grinder yesandla ngesikhathi ukuze kube lula ukulingana okuhle phakathi kwe-roller yokucindezela kanye nokufa kwendandatho;

4. Impahla eluhlaza kufanele ihlanzwe kuqala futhi ihlukaniswe kazibuthe ngaphambi kwe-pelletizer ukuze kuncishiswe ukucindezelwa kwensimbi embobeni yokufa. Nokuhlola imbobo yokufa njalo ukuze ubone ukuthi akukho yini ukuvaleka. Khipha noma ubhoboze imbobo yesikhunta evinjiwe ngesikhathi;

5. Ukuguqulwa kwePlastiki kwembobo yekhoni yomhlahlandlela ye-ring die kufanele kulungiswe. Lapho kulungiswa, kufanele kuqashelwe ukuthi ingxenye ephansi kakhulu yendawo engaphakathi yokusebenza yendandatho efayo kufanele ibe ngu-2mm ngaphezu kwephansi le-groove ye-overtravel, futhi kusekhona indawo yokulungisa i-shaft eccentric ye-roller yokucindezela ngemva kokulungiswa Uma kungenjalo, indandatho kufanele ilahlwe;

6. Igobolondo le-roller yokucindezela lenziwe ngezinto ze-alloy ezingagugi ngokucubungula igolide nokwelashwa kokushisa. Ifomu elingaphezulu kwezinyo legobolondo le-roller yokucindezela linethonya elithile ekusebenzeni kwe-granulation.

Iphrofayili yezinyo legobolondo elivame ukusetshenziswa: iphrofayili yezinyo ngohlobo, iphrofayili yezinyo hhayi ngohlobo, uhlobo lwembobo.

1. Ama-Pass and tooth groove rollers asetshenziswa kakhulu ekugayeni imfuyo nezinkukhu. Inzuzo yama-pass rollers ukuthi i-ring die igqoka ngokulinganayo, kodwa ukusebenza kwekhoyili kubi.

2.I-tooth groove shape pressure roller inokusebenza okuhle kwekhoyili futhi ivame ukusetshenziswa ezimbonini eziphakelayo, kodwa ukuguga kweringi akufani. Irola yokucindezela yomumo we-toove groove enonqenqema oluvalekayo ifaneleka kakhulu ukugaywa kwezinto zasemanzini. Shelelisela nhlangothi zombili.

I-HELICAL ROLLER SHELL

Igobolondo le-roller lingenye yezingxenye eziyinhloko zokusebenza ze-pellet mill. Isetshenziselwa ukucubungula ama-pellets ahlukahlukene e-biofuel, ukudla kwezilwane namanye ama-pellets. Isebenzisa i-alloy steel eqinile engagugi (40Cr, 20Crmnti, Gcr15), ukwelashwa kokushisa kwe-carburizing, ubulukhuni obufanayo. Impilo yesevisi yinde, futhi kunezinhlobo ezahlukene zezakhiwo ezifana nokumise okwezinyo, okuvimbekile okumise okwezinyo, nokumise okwembobo. Ingxenye ye-roller ecindezelayo yenziwe nge-eccentric shaft yangaphakathi nezinye izingxenye ezinobukhulu obunembile, okulula ukulungisa ibanga phakathi kwe-roller ecindezelayo kanye nokufa kwendandatho ngokuya ngezidingo zokukhiqiza komsebenzisi, futhi kulula ukugoqa nokuyifaka, futhi kulula ukufaka esikhundleni igobolondo roller ngokucindezela.

Izinyathelo zokuzivikela:

1. Khetha kahle isilinganiso esifanele sokucindezelwa kwembobo yokufa;

2. Lungisa kahle igebe elisebenzayo phakathi kweringi kanye nerola yokucindezela ukuze libe phakathi kuka-0.1 no-0.3mm (i-rola yokucindezela ishayelwa ukufa kweringi ngemva kokuba i-granulator entsha ivulwe esimweni “esifana nokuzungeza kodwa esingazungezi”) ;

3. I-ring entsha kufanele isetshenziswe ne-rola yokucindezela entsha, futhi i-pressure roller kanye ne-ring die kufanele ikhululeke ngaphambili bese iqiniswa. Uma amakhona abukhali avela ezinhlangothini zombili ze-roller yokucindezela, i-flange ye-roller yokucindezela kufanele ihanjiswe nge-grinder yesandla ngesikhathi ukuze kube lula ukulingana okuhle phakathi kwe-roller yokucindezela kanye nokufa kwendandatho;

4. Impahla eluhlaza kufanele ihlanzwe kuqala futhi ihlukaniswe kazibuthe ngaphambi kwe-pelletizer ukuze kuncishiswe ukucindezelwa kwensimbi embobeni yokufa. Nokuhlola imbobo yokufa njalo ukuze ubone ukuthi akukho yini ukuvaleka. Khipha noma ubhoboze imbobo yesikhunta evinjiwe ngesikhathi;

5. Ukuguqulwa kwePlastiki kwembobo yekhoni yomhlahlandlela ye-ring die kufanele kulungiswe. Lapho kulungiswa, kufanele kuqashelwe ukuthi ingxenye ephansi kakhulu yendawo engaphakathi yokusebenza yendandatho efayo kufanele ibe ngu-2mm ngaphezu kwephansi le-groove ye-overtravel, futhi kusekhona indawo yokulungisa i-shaft eccentric ye-roller yokucindezela ngemva kokulungiswa Uma kungenjalo, indandatho kufanele ilahlwe;

6. Igobolondo le-roller yokucindezela lenziwe ngezinto ze-alloy ezingagugi ngokucubungula igolide nokwelashwa kokushisa. Ifomu elingaphezulu kwezinyo legobolondo le-roller yokucindezela linethonya elithile ekusebenzeni kwe-granulation.

Iphrofayili yezinyo legobolondo elivame ukusetshenziswa: iphrofayili yezinyo ngohlobo, iphrofayili yezinyo hhayi ngohlobo, uhlobo lwembobo.

1. Ama-Pass and tooth groove rollers asetshenziswa kakhulu ekugayeni imfuyo nezinkukhu. Inzuzo yama-pass rollers ukuthi i-ring die igqoka ngokulinganayo, kodwa ukusebenza kwekhoyili kubi.

2.I-tooth groove shape pressure roller inokusebenza okuhle kwekhoyili futhi ivame ukusetshenziswa ezimbonini eziphakelayo, kodwa ukuguga kweringi akufani. Irola yokucindezela yomumo we-toove groove enonqenqema oluvalekayo ifaneleka kakhulu ukugaywa kwezinto zasemanzini. Shelelisela nhlangothi zombili.