Ukuqina kwezinhlayiya kungenye yezinkomba zekhwalithi zonke izinkampani eziphakelayo ezinaka kakhulu. Ekuphakeleni kwemfuyo nezinkukhu, ubulukhuni obuphezulu buzobangela ukunganambiki kahle, ukunciphisa ukudla okudliwayo, futhi kubangele izilonda emlonyeni ezingulubeni ezincelayo. Kodwa-ke, uma ubulukhuni buphansi, okuqukethwe kwe-powder kuzokwehla. Ukwenyuka, ikakhulukazi ubulukhuni obuphansi bezinto ze-pellet kuzophinde kubangele izici zekhwalithi ezingezinhle ezifana nokuhlukaniswa kwesiphakeli. Ngakho-ke, amabhizinisi kufanele aqinisekise ukuthi ubulukhuni bokudla buhlangabezana nezindinganiso zekhwalithi. Ngaphezu kokulungiswa kwefomula yokuphakelayo, baphinde bagxile ezigabeni ezihlukahlukene zokukhiqiza nokucubungula, okuzoba nomthelela obalulekile ebulukhunini besiphakeli se-pellet.

I-1) Isici esidlala indima ebalulekile ebulukhuni bezinhlayiya enqubweni yokugaya ubukhulu bezinhlayiyana zokugaya zezinto zokusetshenziswa. Ngokuvamile, lapho usayizi wezinhlayiyana zokugaya ucoleka wezinto ezingavuthiwe, kuba lula ukuthi isitashi sigcwale ngesikhathi senqubo yokumisa isimo, futhi kuqina umphumela wokubopha kuma-pellets. Ukuphuka kalula, ukuqina okukhulu. Ngakho-ke, ekukhiqizweni kwangempela, usayizi wezinhlayiya ezichotshozwayo udinga ukulungiswa ngokufanele ngokuya ngokusebenza kokukhiqiza kwezilwane ezehlukene kanye nobukhulu bomgodi wokufa weringi.

I-2) Ngokwelashwa okukhukhumezayo kwezinto zokusetshenziswa, ubuthi obusezintweni zokusetshenziswa bungasuswa, amabhaktheriya angabulawa, izinto eziyingozi zingaqedwa, amaprotheni asezintweni zokusetshenziswa angakhishwa, futhi isitashi singagcwaliswa ngokugcwele. Njengamanje, izinto zokusetshenziswa ezikhukhumele zisetshenziswa kakhulu ekukhiqizeni ukudla kwezingulube ezincelisayo ezisezingeni eliphezulu kanye nokudla okukhethekile komkhiqizo wasemanzini. Emikhiqizweni ekhethekile yasemanzini, ngemva kokuba izinto zokusetshenziswa zikhukhumezekile, izinga le-starch gelatinization liyakhula futhi ubulukhuni bezinhlayiya ezibunjiwe buyanda, okuzuzisa ukuthuthukisa ukuzinza kwezinhlayiya emanzini. Ngokudla kwengulube encelisayo, izinhlayiya zidingeka ukuthi zibe crispy futhi zingabi lukhuni kakhulu, okuzuzisa ukuphakela kwezingulube ezincelisayo. Kodwa-ke, ngenxa yezinga eliphezulu le-starch gelatinization kuma-pellets ezingulube ezincelisayo ezikhukhumezayo, ukuqina kwamapellets okuphakelayo nakho kukhulu kakhulu.

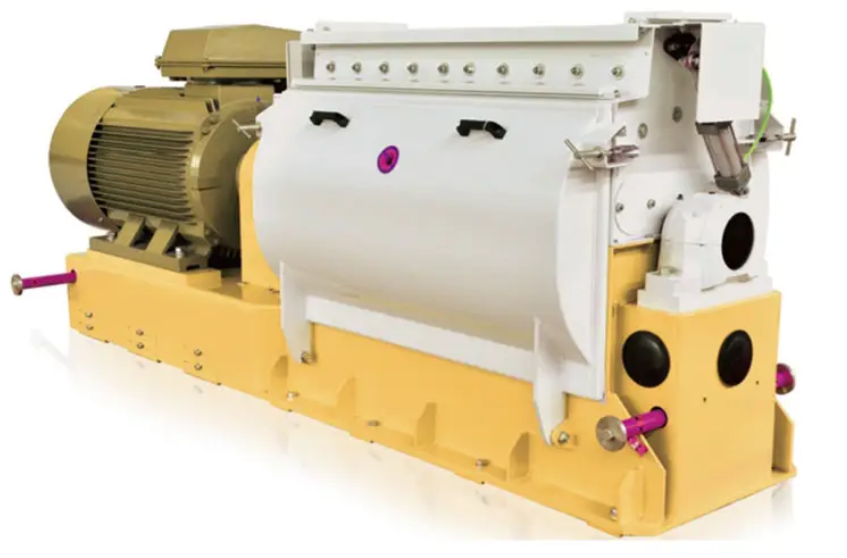

3) Ukuhlanganiswa kwezinto ezingavuthiwe kungathuthukisa ukufana kwezingxenye ezihlukahlukene zosayizi wezinhlayiyana, okuzuzisa ukugcina ubulukhuni bezinhlayiyana buhambisana ngokuyisisekelo futhi kuthuthukisa ikhwalithi yomkhiqizo. Ekukhiqizeni ukudla kwe-pellet eqinile, ukwengeza umswakama ongu-1% kuya ku-2% ku-mixer kuzosiza ukuthuthukisa ukuqina nokuqina kokuphakelayo kwe-pellet. Kodwa-ke, kuyadingeka futhi ukucabangela imiphumela emibi yokwanda komswakama ekomisweni nasekupholiseni ama-pellets. Futhi ayihambisani nokugcinwa komkhiqizo. Ekukhiqizeni ukudla kwe-pellet okumanzi, umswakama ofinyelela ku-20% kuya ku-30% ungangezwa kumpushana. Kulula ukwengeza umswakama ongaba ngu-10% phakathi nenqubo yokuhlanganisa kunesikhathi senqubo yokumisa. Ama-pellets akhiwe ngezinto ezinomswakama ophezulu anobunzima obuphansi, ukuthamba kanye nokuthakazelisa okuhle. Amabhizinisi amakhulu azalelayo angasebenzisa lesi siphakeli se-pellet esimanzi. Ama-pellets amanzi ngokuvamile akulula ukuwagcina futhi ngokuvamile adingeka ukuthi anikezwe ngokushesha ngemva kokukhiqizwa. Ukwengeza uwoyela ngesikhathi sokuxuba kuyindlela evame ukusetshenziswa yokwengeza uwoyela kumaworkshop okukhiqiza okuphakelayo. Ukwengeza u-1% kuya ku-2% wamafutha kunomphumela omncane ekunciphiseni ubulukhuni bezinhlayiya, kuyilapho ukwengeza u-3% kuya ku-4% wamafutha kunganciphisa kakhulu ubulukhuni bezinhlayiya.

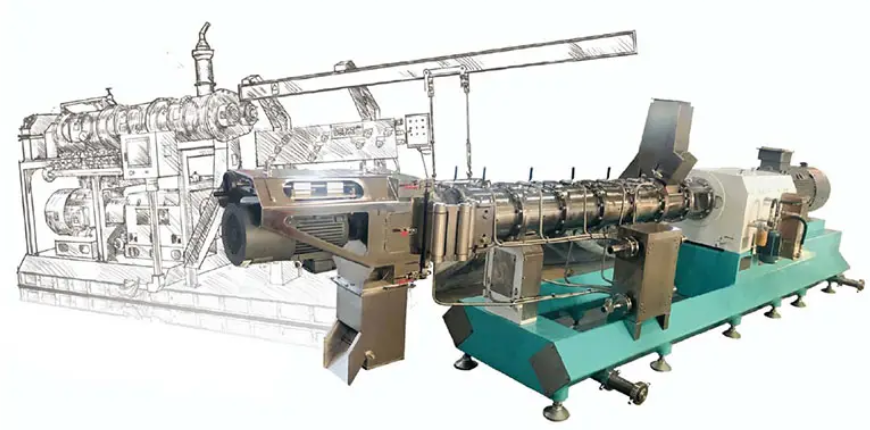

I-4) I-steam conditioning iyinqubo eyinhloko ekucubunguleni ukudla kwe-pellet, futhi umphumela wokulungisa uthinta ngokuqondile isakhiwo sangaphakathi kanye nekhwalithi yokubukeka kwamapellets. Ikhwalithi ye-steam nesikhathi sokumisa yizici ezimbili ezibalulekile ezithinta umphumela wokulungisa. I-steam eyomile negcwele ikhwalithi ephezulu inganikeza ukushisa okwengeziwe ukwandisa izinga lokushisa lezinto futhi i-gelatinize isitashi. Uma isikhathi sokumisa sithatha isikhathi eside, izinga le-starch gelatinization liyakhuphuka. Lapho inani liphakeme, i-denser yesakhiwo sezinhlayiyana ngemva kokwakhiwa, ngcono ukuzinza, kanye nokuqina okukhulu. Okokuphakela izinhlanzi, amajakhethi anengqimba ephindwe kabili noma anezingqimba eziningi ngokuvamile asetshenziselwa ukubeka isimo ukuze kukhuliswe izinga lokushisa lesimo nokwelula isikhathi sokumisa. Kungcono kakhulu ekuthuthukiseni ukuzinza kwezinhlayiya zokudla kwezinhlanzi emanzini, futhi ubulukhuni bezinhlayiya buyakhula ngokufanele.

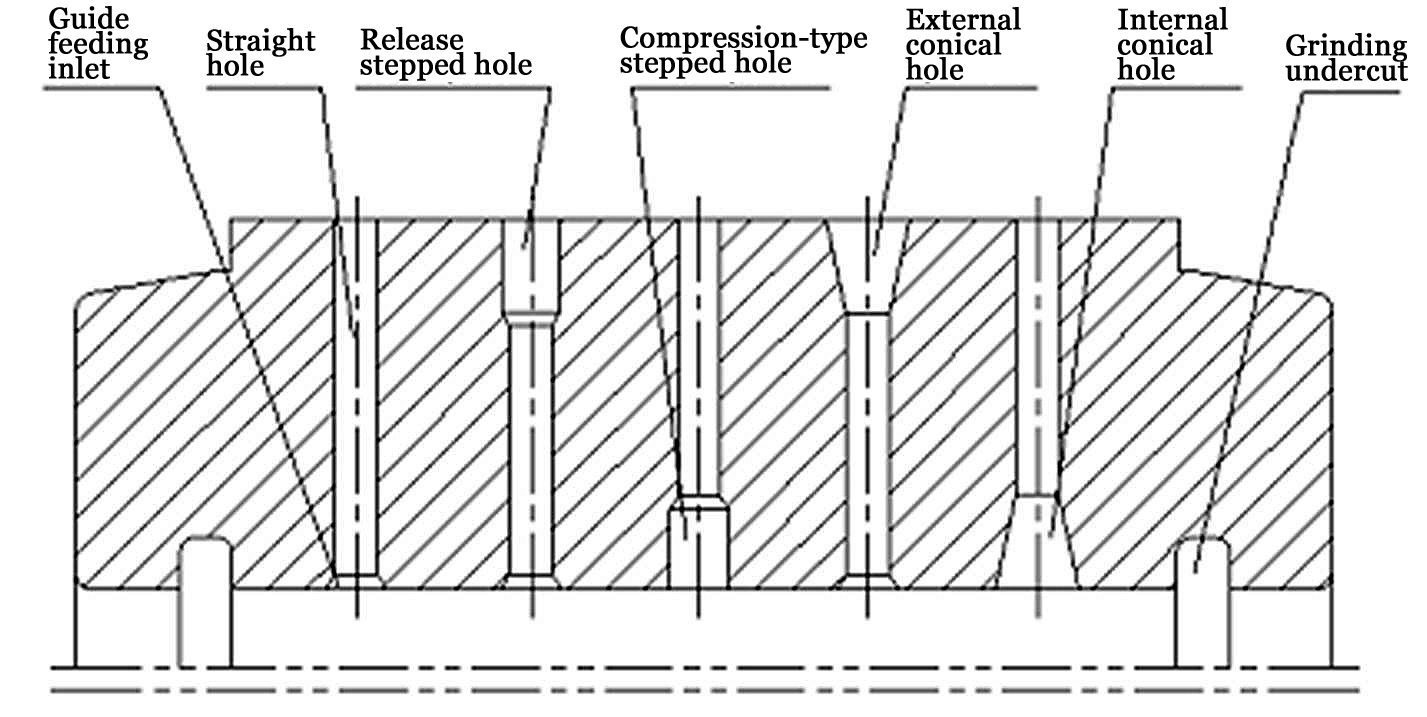

5) Ngesikhathi senqubo ye-granulation, imingcele yezobuchwepheshe efana ne-aperture kanye ne-compression ratio ye-ring die izophinde ithinte ubulukhuni bezinhlayiya. Ukuqina kwezinhlayiya ezakhiwe yisikhunta esiyindandatho esinembobo efanayo kodwa izilinganiso zokucindezela ezihlukene zizokhula kakhulu ngokwanda kwesilinganiso sokucindezela. . Ukukhetha idayi yeringi enesilinganiso sokuminyanisa esifanele kungaveza izinhlayiya ezinobulukhuni obufanele. Ngesikhathi esifanayo, ubude bezinhlayiya bubuye bube nomthelela omkhulu emandleni okucindezela izinhlayiya. Ngezinhlayiya ezinobubanzi obufanayo, uma izinhlayiya zingenawo amaphutha, ubude bezinhlayiyana buba bukhulu, ubulukhuni obulinganisiwe bukhulu. Ngakho-ke, ukulungisa isikhundla somsiki ukuze kugcinwe ubude bezinhlayiyana ezifanele kungagcina ubulukhuni bezinhlayiya ngokuyisisekelo buhambisana. Ububanzi bezinhlayiyana kanye nokuma kwe-cross-sectional nakho kunomthelela othize kubulukhuni bezinhlayiyana. Ngaphezu kwalokho, izinto zendandatho ziyafa nazo zinomthelela othile ekubukekeni kwekhwalithi kanye nokuqina kwamapellets. Kunomehluko osobala phakathi kokuphakelayo kwe-pellet okukhiqizwa yindandatho yensimbi evamile efayo nendandatho yensimbi engagqwali iyafa.

Ukuze kwandiswe isikhathi sokugcinwa kwemikhiqizo yokuphakelayo futhi kuqinisekiswe ikhwalithi yomkhiqizo phakathi nenkathi ethile yesikhathi, ukoma okudingekayo nokupholisa izinhlayiya zokudla kuyadingeka.