Ngokusho kwe-International Food Industry Federation (IFIF), ukukhiqizwa kwaminyaka yonke kokudla okuhlanganisiwe kulinganiselwa emathani angaphezu kwebhiliyoni eyodwa kanti inzuzo yaminyaka yonke yokukhiqizwa kokudla okudayiswayo ilinganiselwa ngaphezu kwezigidigidi ezingama-400 zamaRandi (ama-394 bhiliyoni).

Abakhiqizi bokuphakelayo abakwazi ukukhokhela isikhathi sokuphumula esingahlelelwe noma ukulahlekelwa umkhiqizo ukuze bahambisane nesidingo esikhulayo. Ezingeni leplanti, lokhu kusho ukuthi kokubili okokusebenza kanye nezinqubo kumele zizinze ukuze kuhlangatshezwane nesidingo kuyilapho kugcinwa umugqa ophansi onempilo.

Ukusebenziseka kalula kubalulekile

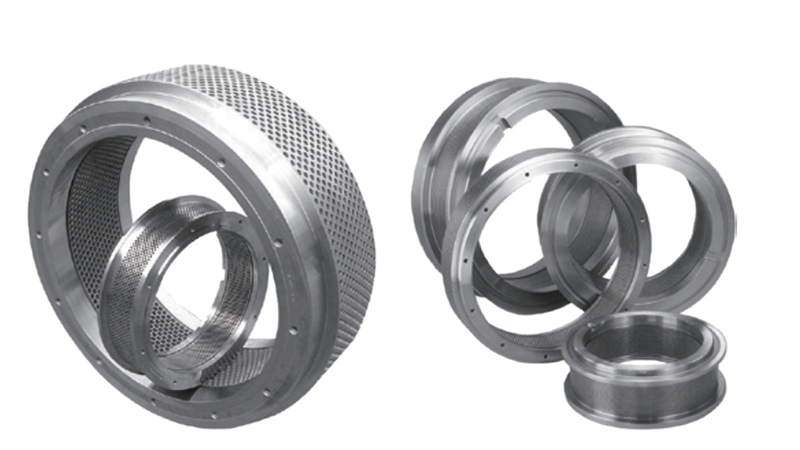

Ubuchwepheshe buyancipha kancane kancane njengoba abasebenzi asebekhulile nabanolwazi bethatha umhlalaphansi futhi abashintshwa ngezinga elidingekayo. Ngenxa yalokho, abasebenzi bemishini yokuphakelayo abanekhono bawusizo olukhulu futhi kunesidingo esikhulayo sokushintsha izinqubo ngendlela enembile nelula, kusukela kubaqhubi kuya ekuphatheni nasekuphathweni kokukhiqiza. Isibonelo, indlela yokwehlukaniswa kwe-automation ingenza kube nzima ukuxhumana namasistimu ahlukene avela kubathengisi abahlukene, yona ngokwayo engadala izinselele ezingadingekile, okuholela ekuphumuleni okungahleliwe. Kodwa-ke, izinkinga ezihlobene nezingxenye eziyisipele (i-pellet mill, i-ring die, i-feed mill) ukutholakala kanye nekhono lesevisi nakho kungaholela ekunciphiseni isikhathi esibizayo.

Lokhu kungagwenywa kalula ngokusebenzisana nomhlinzeki wesixazululo sebhizinisi. Ngoba ibhizinisi lisebenzelana nomthombo owodwa wobungcweti kuzo zonke izici zefekthri nezinqubo zayo ezihlobene kanye nezimfuneko ezifanele zokulawula. Esitshalweni sokudla kwezilwane, izici ezifana nomthamo onembile wezithasiselo ezimbalwa, ukulawulwa kwezinga lokushisa, ukulawulwa kokugcinwa komkhiqizo kanye nokunciphisa imfucuza ngokuwasha kungalawulwa ngokunembile, kuyilapho kugcinwa izinga eliphezulu lokuphepha kokuphakelayo. Izidingo zokuphepha kokuphakelayo zingafinyelelwa. Inani lokudla okunomsoco. Lokhu kuthuthukisa ukusebenza okuphelele futhi ekugcineni izindleko ngethani lomkhiqizo. Ukuze kwandiswe imbuyiselo ekutshalweni kwezimali futhi kwehliswe izindleko eziphelele zobunikazi, isinyathelo ngasinye kufanele sifanelane nomsebenzi ngamunye kuyilapho kuqinisekiswa ukukhanya okugcwele kwenqubo.

Ukwengeza, ukuxhumana okuseduze nabaphathi bama-akhawunti abazinikele, onjiniyela bemishini nabacubungula kuqinisekisa ukuthi amandla obuchwepheshe nokusebenza kwezixazululo zakho ezishintshayo kuhlala kuvikelwe. Leli khono lokulawula inqubo ngokugcwele liqinisekisa umkhiqizo wekhwalithi ephezulu futhi lengeza ukulandeleka okwakhelwe ngaphakathi kuma-elementi akhuphuka nomfula uma kudingeka. Zonke izinqubo zokukhiqiza zisekelwa ku-inthanethi noma esizeni, kusukela eku-odeni uhlelo lokulawula ukuqondisa usekelo nge-inthanethi.

Ukwandisa ukutholakala: ukukhathazeka okumaphakathi

Izixazululo zasefekthri zingahlukaniswa njenganoma yini kusukela kumshini womshini wengxenye eyodwa kuya ekufakweni odongeni noma endaweni eluhlaza, kodwa okugxilwe kuyo kuyefana kungakhathaliseki usayizi wephrojekthi. Okungukuthi, indlela uhlelo, umugqa noma isitshalo sonke esinikeza ngayo okudingekayo ukuze kukhiqizwe imiphumela emihle. Impendulo ilele ekutheni izixazululo zenziwa kanjani, zisetshenziswe futhi zenziwe kahle kanjani ukuze zinikeze ukutholakala okuphezulu ngokuya ngamapharamitha amisiwe. Ukukhiqiza kuyibhalansi phakathi kokutshalwa kwezimali kanye nenzuzo, futhi udaba lwebhizinisi luyisisekelo sokunquma ukuthi yiliphi izinga okufanele kufinyelelwe kulo. Yonke imininingwane ethinta amazinga okukhiqiza iyingozi ebhizinisini lakho, futhi sincoma ngokuqinile ukushiyela isenzo sokulinganisa kochwepheshe.

Ngokususa ukuxhumana okudingekayo phakathi kwabahlinzeki abanomhlinzeki wezixazululo zebhizinisi elilodwa, abanikazi bebhizinisi banozakwethu onomthwalo wemfanelo futhi oziphendulela. Isibonelo, amafekthri adinga ukutholakala kwezingxenye eziyisipele nezingxenye zokugqoka ezifana nezando ze-Hammermill, izikrini, amaroli e-Roller mill/Flaking mill, i-Pellet mill dies, i-mill rolls nezingxenye zokugaya njll. Kufanele zitholwe ngesikhathi esifushane ngangokunokwenzeka futhi zifakwe futhi zigcinwe ngu ochwepheshe. Uma ungumhlinzeki wesixazululo sefekthri, ngisho noma ezinye izici zidinga umhlinzeki wenkampani yangaphandle, yonke inqubo inganikezwa ngaphandle.

Bese usebenzisa lolu lwazi ezindaweni ezibalulekile njengokubikezela. Ukwazi ukuthi isistimu yakho idinga nini ukulungiswa kubalulekile ekwehliseni isikhathi sokungasebenzi kanye nokwandisa umkhiqizo. Isibonelo, isigayo se-pellet sivame ukusebenza ngesisekelo se-24/7, ngakho-ke lokhu kuyisisekelo ekusebenzeni kwabo ngempumelelo. Izixazululo ezitholakala emakethe namuhla ziqapha futhi zandise ukusebenza ngesikhathi sangempela, ziqondisa izici ezifana nokudlidliza futhi zixwayise opharetha ngesikhathi sokungasebenzi kahle okungenzeka ukuze bakwazi ukuhlela isikhathi sokuphumula ngokufanele. Ezweni elihle, isikhathi sokuphumula singangena ezincwadini zomlando, kodwa empeleni kunjalo. Umbuzo uthi kwenzekani uma lokho kwenzeka. Uma impendulo kungeyona "uzakwethu wesisombululo sefekthri useyixazululile le nkinga", mhlawumbe sekuyisikhathi soshintsho.