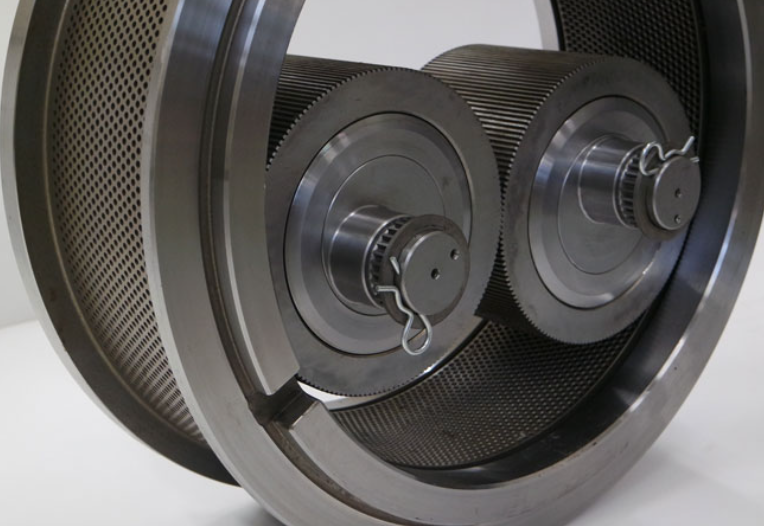

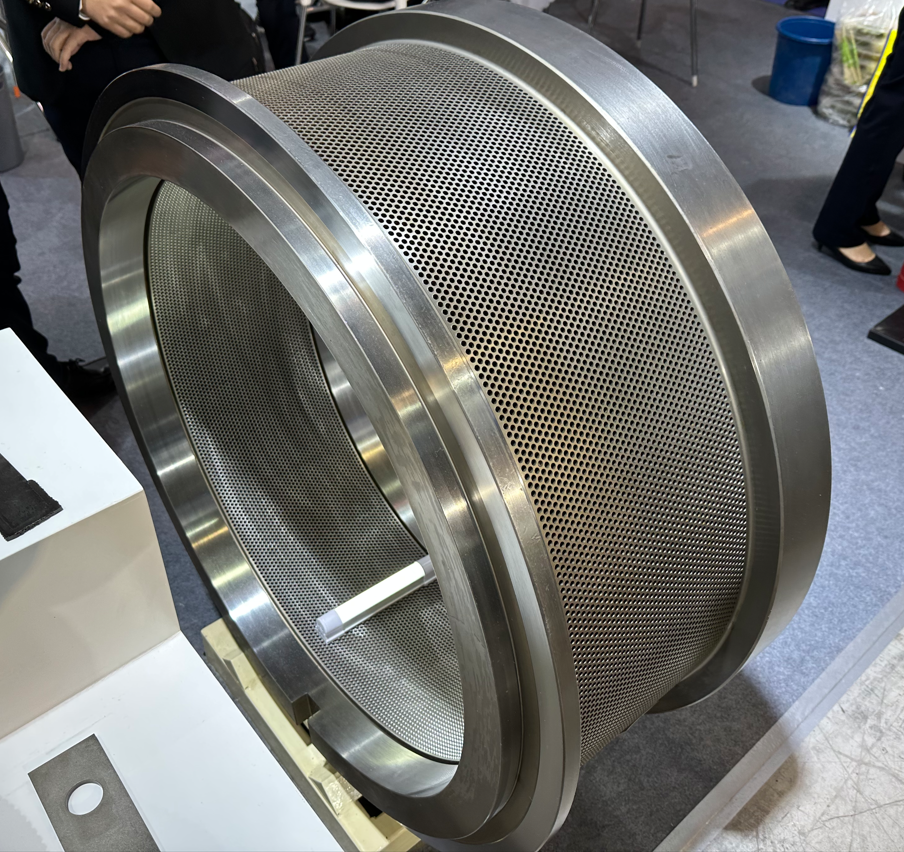

Ngokugqugquzelwa kanye nokusetshenziswa kwe-pellet feed emfuyweni nasezinkukhuni, embonini yezolimo zasemanzini, nezimboni ezisafufusa ezifana nomanyolo oyinhlanganisela, amahops, ichrysanthemum, ama-wood chips, amagobolondo amakinati, kanye nempuphu ye-cottonseed, amayunithi anda asebenzisa izigayo ze-ring die pellet. Ngenxa yokuhluka kwefomula yokuphakelayo kanye nomehluko wesifunda, abasebenzisi banezidingo ezihlukile zokuphakelayo kwe-pellet. Umkhiqizi ngamunye wokuphakelayo udinga ikhwalithi enhle ye-pellet kanye nokusebenza kahle okuphezulu kwe-pelleting kokuphakelayo kwe-pellet akukhiqizayo. Ngenxa yamafomula okuphakelayo ahlukene, ukukhethwa kwamapharamitha e-ring die uma ucindezela lezi zifunzo ze-pellet nakho kuhlukile. Imingcele ibonakala ngokuyinhloko ekukhethweni kwezinto ezibonakalayo, ububanzi be-pore, ukwakheka kwembotshana, i-aspect ratio, kanye nesilinganiso sokuvula. Ukukhethwa kwamapharamitha e-ring die kumele kunqunywe ngokuya ngamakhemikhali kanye nezakhiwo ezibonakalayo zezinto ezihlukahlukene zokusetshenziswa ezakha ifomula yokudla. Ukwakheka kwamakhemikhali ezinto ezingavuthiwe ikakhulukazi kuhlanganisa amaprotheni, isitashi, amafutha, i-cellulose, njll. Izici ezibonakalayo zezinto ezingavuthiwe ikakhulukazi zihlanganisa usayizi wezinhlayiyana, umswakama, umthamo, njll.

Ukudla kwemfuyo nezinkukhu ikakhulukazi kuqukethe ukolweni nommbila, okunesitashi esiningi kanye ne-fiber ephansi. Kuwukudla okunesitashi esiphezulu. Ukuze ucindezele lolu hlobo lokuphakelayo, kufanele kuqinisekiswe ukuthi isitashi sigcwele i-gelatinized futhi sihlangabezana nezinga lokushisa eliphezulu kanye nezimo zokucubungula. Ugqinsi lwendandatho yokufa ngokuvamile luwugqinsi, futhi indawo yokuvula Ububanzi bubanzi, futhi ukubukeka kwe-aspect ratio ngokuvamile kuphakathi kuka-1: 8-1: 10. Izinkukhu ze-broiler namadada ziwukudla okunamandla amakhulu okunamafutha amaningi, imbudumbudu elula, kanye nobude nobubanzi obukhulu obuphakathi kuka-1:13.

Ukudla kwasemanzini kufaka phakathi ukudla kwezinhlanzi, ukudla kwezimfanzi, ukudla kofudu olunamagobolondo athambile, njll. Isiphakeli sezinhlanzi sinefiber engahluziwe ephezulu, kuyilapho ukudla kwezimfanzi kanye nokudla kofudu olunamagobolondo athambile kunokuqukethwe kwefayibha engahluziwe ephansi kanye nokuqukethwe kwamaprotheni amaningi, okuyingxenye ephezulu. - ukudla kwamaprotheni. Izinto zasemanzini zidinga ukuzinza kwesikhathi eside kwezinhlayiya emanzini, ububanzi obungaguquki kanye nobude obucocekile, obudinga ubungako bezinhlayiyana ezincane kanye nezinga eliphezulu lokuvuthwa lapho impahla igayiwe, kanye nezinqubo zokuvuthwa ngaphambi kokuvuthwa nangemva kokuvuthwa kuyasetshenziswa. Ububanzi beringi esetshenziselwa ukudla kwezinhlanzi ngokuvamile buphakathi kuka-1.5-3.5 , futhi ububanzi besilinganiso ngokuvamile buphakathi kuka-1 : 10-1 : 12 . Ibanga lokuvula leringi elisetshenziselwa ukudla kwezimfanzi liphakathi kuka-1.5-2.5 , futhi ububanzi besilinganiso sobude ukuya kububanzi buphakathi kuka-1:11-1:20 . Amapharamitha athile esilinganiso sobude ukuya kobubanzi akhethiwe Kufanele kunqunywe ngokuya ngezinkomba zokudla okunomsoco kufomula kanye nezidingo zabasebenzisi. Ngesikhathi esifanayo, ukuklanywa komumo we-die hole akusebenzisi izimbobo ezinyathelwe ngangokunokwenzeka ngaphansi kwesimo sokuvumela amandla, ukuze kuqinisekiswe ukuthi izinhlayiya ezisikiwe zinobude obufanayo nobubanzi.

Ifomula yomanyolo eyinhlanganisela ikakhulukazi iqukethe umanyolo we-inorganic, umanyolo we-organic namaminerali. Umanyolo wezinto ezingaphili kumanyolo oyinhlanganisela njenge-urea ugqwala kakhulu kwindandatho, kuyilapho amaminerali alimaza kakhulu imbobo yokufa kanye nembobo yekhoni yangaphakathi yeringi iyafa, futhi amandla e-extrusion aphezulu kakhulu. enkulu. I-diameter yembobo ye-compound fertilizer ring die ngokuvamile inkulu, isukela ku-3 kuya ku-6. Ngenxa ye-coefficient enkulu yokugqoka, imbobo yokufa inzima ukuyikhipha, ngakho-ke isilinganiso sobude kuya kububanzi sincane, ngokuvamile siphakathi kuka-1:4 -1: 6 . Umanyolo uqukethe amabhaktheriya, futhi izinga lokushisa akufanele lidlule ama-50-60 degrees, ngaphandle kwalokho kulula ukubulala amagciwane. Ngakho-ke, umanyolo ohlanganisiwe udinga izinga lokushisa eliphansi le-granulation, futhi ngokuvamile ubukhulu bodonga lwe-ring die buncane kakhulu. Ngenxa yokuguga okukhulu kanye nokudabuka kukamanyolo oyinhlanganisela embotsheni yokufa eyindandatho, izidingo kububanzi bembobo aziqinile kakhulu. Ngokuvamile, i-ring die idayiwe lapho igebe phakathi kwama-roller okucindezelayo lingakwazi ukulungiswa. Ngakho-ke, ubude bembobo enyathelwe busetshenziselwa ukuqinisekisa i-aspect ratio futhi kuthuthukiswe impilo yokugcina yesevisi ye-ring die.

Okuqukethwe kwe-fiber engahluziwe kuma-hops kuphezulu futhi kuqukethe izinhlobo, futhi izinga lokushisa ngokuvamile alikwazi ukudlula ama-degree angu-50, ngakho-ke ubukhulu bodonga lwendandatho yokufa kwama-hops okucindezela buncane, futhi ubude nobubanzi bufushane, ngokuvamile buba ngu-1: 5, futhi ububanzi bezinhlayiyana bukhulu ku-5-6 phakathi.

I-Chrysanthemum, amagobolondo amakinati, umphako we-cottonseed, kanye ne-sawdust kuqukethe inani elikhulu le-fiber eluhlaza, okuqukethwe kwe-fiber engahluziwe kungaphezu kuka-20%, okuqukethwe kukawoyela kuphansi, ukumelana nokungqubuzana kwezinto ezidlula emgodini kukhulu, i-granulation. ukusebenza akulungile, futhi ubulukhuni bezinhlayiyana buyadingeka. Okuphansi, kunzima ukuhlangabezana nezidingo uma kungakhiwa ngokuvamile, ububanzi bezinhlayiyana bukhulu kakhulu, ngokuvamile phakathi kuka-6-8, futhi isilinganiso sesici ngokuvamile singu-1: 4-1: 6. Ngenxa yokuthi lolu hlobo lokuphakelayo lunomthamo omncane wenqwaba kanye nobubanzi obukhulu bembobo yokufa, i-tape kufanele isetshenziselwe ukuvala indilinga yangaphandle yendawo yokufa ngaphambi kwe-granulation, ukuze impahla igcwaliswe ngokugcwele emgodini wokufa futhi yenziwe. , bese idatshulwa ikhasethi.

Ukuze uthole i-granulation yezinto ezihlukahlukene, inkolelo-mbono ayikwazi ukulandelwa ngokuqinile. Kuyadingeka ukukhetha amapharamitha e-ring die afanele kanye nezimo zokusebenza ngokuya ngezici ze-granulation zezinto kanye nezici ezithile zomkhiqizi ngamunye wokuphakelayo. Kuphela ngokuzivumelanisa nezimo zendawo lapho kungakhiqizwa ukudla okuseqophelweni eliphezulu.

Ukuhlaziywa Kwembangela kanye Nendlela Yokuthuthukisa Yezinhlayiya Ezingavamile

Amayunithi okukhiqiza okuphakelayo avame ukuba nama-pellets angavamile lapho ekhiqiza ukudla, okuthinta ukubukeka kanye nekhwalithi yangaphakathi yama-pellets, ngaleyo ndlela kuthinte ukuthengiswa kanye nedumela lemboni yokuphakelayo. Okulandelayo uhlu lwezizathu zezinhlayiya ezingavamile ezivame ukwenzeka ezigayweni zokuphakelayo kanye nohlu lwezindlela zokuthuthukisa eziphakanyisiwe:

| inombolo yomkhiqizo | Izici zomumo | imbangela | Kunconywa ukushintsha |

| 1 | Kunemifantu eminingi ohlangothini olungaphandle lwezinhlayiya ezigobile | 1. Umsiki ukude kakhulu neringi futhi buthuntu 2. Impushana ijiyile kakhulu 3. Ukuqina kokuphakelayo kuphansi kakhulu | 1. Hambisa i-cutter bese ushintsha i-blade 2. Thuthukisa ukucoleka okuchotshozwayo 3. Khulisa ubude obusebenzayo bomgodi wokufa 4. Faka ama-molasses noma amafutha |

| 2 | Kuvela imifantu evundlile evundlile | 1. Ifayibha yinde kakhulu 2. Isikhathi sokuthambisa sifushane kakhulu 3. Umswakama owedlulele | 1. Lawula ukuqina kwefayibha 2. Nweba isikhathi sokuguquguquka 3. Lawula izinga lokushisa lezinto ezingavuthiwe futhi unciphise umswakama ekushiseni |

| 3 | Izinhlayiya zikhiqiza imifantu eqondile | 1. Impahla eluhlaza iyanwebeka, okungukuthi, izokhula ngemva kokucindezelwa 2. Amanzi amaningi, imifantu ivela lapho kupholisa 3. Isikhathi sokuhlala emgodini wokufa sifushane kakhulu | 1. Thuthukisa ifomula futhi wandise ukuminyana kokuphakelayo 2. Sebenzisa isitimu esomile esigcwele ukuthambisa 3. Khulisa ubude obusebenzayo bomgodi wokufa |

| 4 | Ukukhishwa kwemisebe kusuka endaweni yomthombo | Khipha izinhlamvu ezinkulu (njengezinhlamvu zommbila uhhafu noma ophelele) | Lawula ukucoliseka kokuchotshozwa kwezinto ezingavuthiwe futhi wandise ukufana kokuchotshozwa |

| 5 | Ingaphezulu lezinhlayiyana alilingani | 1. Ukufakwa kwezinto zokusetshenziswa ezinohlamvu olukhulu, ukufutheka okunganele, okungathambile, okuphuma phezulu 2. Kunamabhamuza kusitimu, futhi ngemva kokuvuthwa, amabhamuza ayaqhuma bese kuvela imigodi. | 1. Lawula ukucoliseka kokuchotshozwa kwezinto ezingavuthiwe futhi ukwandise ukufana kokuchotshozwa 2. Thuthukisa izinga lomusi |

| 6 | Izikhwebu | Isitimu esiningi kakhulu, ukucindezela okukhulu, izinhlayiya zishiya indandatho ifa futhi iqhume, okwenza izinhlayiya zefiber ziphume phezulu bese zenza amadevu. | 1. Yehlisa umfutho we-steam, sebenzisa umusi we-low-pressure ( 15- 20psi ) ukucisha nokushisa 2. Naka ukuthi indawo ye-valve yokunciphisa ingcindezi inembile. |

| uhlobo lwezinto ezibonakalayo | uhlobo lokuphakelayo | Imbobo yokufa indandatho |

| ukudla kwesitashi esiphezulu | Φ2-Φ6 | |

| Amapellets emfuyo | high energy feed | Φ2-Φ6 |

| Ama-pellets okudla kwamanzi | ukudla okuphezulu kwamaprotheni | Φ1.5-Φ3.5 |

| I-Compound Fertilizer Granules | okuphakelayo okune-urea | Φ3-Φ6 |

| ama-pellets we-hop | ukudla okuphezulu kwe-fiber | Φ5-Φ8 |

| I-Chrysanthemum Granules | ukudla okuphezulu kwe-fiber | Φ5-Φ8 |

| Igobolondo le-Peanut Granules | ukudla okuphezulu kwe-fiber | Φ5-Φ8 |

| I-Cottonseed Hull Granules | ukudla okuphezulu kwe-fiber | Φ5-Φ8 |

| I-Peat pellets | ukudla okuphezulu kwe-fiber | Φ5-Φ8 |

| amapulangwe ezinkuni | ukudla okuphezulu kwe-fiber | Φ5-Φ8 |