I-die iyingxenye eyinhloko emshinini we-pellet. Futhi kuyisihluthuleloukwenza ama-feed pellets. Ngokwezibalo ezingaphelele, izindleko ze-pellet mill die loss zenza ngaphezu kuka-25% wezindleko zokulungisa yonke indawo yokusebenzela yokukhiqiza. Kuwo wonke amaphuzu akhuphukayo ezinkokhelweni, ukuncintisana kwemakethe yakho kwehla ngo-0.25%. Ngakho-ke imininingwane ye-pellet mill ibaluleke kakhulu.

U-Shanghai Zhengyi (CPSHZY) unguchwepheshefeed pellet millumphakeli e-china. Sihlinzeka ngomshini wokugaya i-ring die pellet, i-flat die pellet mill kanye ne-izingxenye ze-pellet mill, njenge-flat die, i-ring die, i-pellet mill roller, nezinye izingxenye zomshini we-pellet.

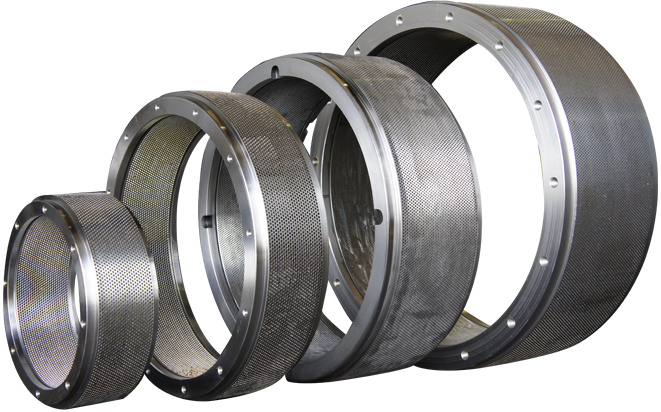

1.Izinto zokufa ze-Pellet Mill

I-pellet mill die ngokuvamile yenziwe nge-carbon steel, i-alloy structural steel noma insimbi engagqwali ngokusebenzisa i-forging, machining, izimbobo zokubhoboza, nezinqubo zokwelashwa kokushisa. Umsebenzisi angakhetha ngokusho ukugqwala kwezinhlayiyana impahla eluhlaza. Impahla ye-pellet mill die kufanele yenziwe ngensimbi yesakhiwo se-alloy noma isikhunta sendandatho yensimbi engagqwali.

Insimbi yesakhiwo sekhabhoni, njengensimbi engu-45, ubulukhuni bayo bokwelapha ukushisa ngokuvamile bungu-45-50 HRC, iyindandatho yokufa yezinga eliphansi, ukumelana kwayo nokugqoka nokugqwala kumpofu, manje sekuphelile ngokuyisisekelo.

I-alloy structural steel, efana ne-40Cr, 35CrMo, njll., enobulukhuni bokwelashwa kokushisa ngaphezu kuka-50HRC kanye nezakhiwo ezinhle ezihlanganisiwe zemishini. I-die eyenziwe yalolu lwazi inamandla amakhulu futhi ingakwazi ukumelana nokugqoka, kodwa okubi ukuthi ukumelana nokugqwala akukuhle, ikakhulukazi ekuphakeleni izinhlanzi.

Intengo yendandatho iyafa, eyenziwe ngezinto ezibonakalayo, ama-marigold pellets, ama-wood chips, ama-straw pellets, njll, aphezulu kakhulu kunensimbi engagqwali. Kokubili i-20CrMnTi kanye ne-20MnCr5 yizinsimbi ze-alloy ephansi, zombili ziyafana, ngaphandle kokuthi eyokuqala iyinsimbi yaseShayina kanye nensimbi yokugcina yaseJalimane. Njengoba i-Ti, into yamakhemikhali, ingavamile ukutholakala phesheya, i-20CrMnTi noma i-20CrMn evela e-China isetshenziswa esikhundleni sika-20MnCr5 yaseJalimane, ngakho ayingeni ngaphakathi kobubanzi bensimbi yesakhiwo se-alloy. Kodwa-ke, ungqimba oluqinile lwale nsimbi lunqunyelwe inqubo ye-carburizing ekujuleni okuphezulu kwe-1.2 mm, okubuye kube inzuzo yentengo ephansi yale nsimbi.

Izinto zensimbi engagqwali zihlanganisa insimbi engagqwali yaseJalimane i-X46Cr13, i-China insimbi engagqwali 4Cr13, njll. Lezi zinto zinokuqina nokuqina okungcono, ubulukhuni bokwelashwa okushisa obuphakeme kunezinsimbi ezishisiwe, izendlalelo eziqinile kunezinsimbi ezishisiwe, nokuguga okuhle nokungagqwali, okuholela ekuphileni okude futhi amanani ngokwemvelo aphakeme kunezinsimbi ezigayiwe. Ngenxa yempilo ende ye-stainless steel die steel, imvamisa yokushintshwa iphansi ngakho-ke izindleko ngethani ziphansi.

Imvamisa, i-die material ye-ring die pellet mill iyinsimbi yesakhiwo sengxubevange nezinto zensimbi engagqwali.

2.Isilinganiso sokucindezela se-pellet mill siyafa

i=d/L

T=L+M

M ukujula kwembobo encishisiwe

I-Compression ratio (i) isilinganiso sobubanzi bomgodi wokufa (d) nobude obusebenzayo (L) bedayizi.

Ngokwemvelo yezinto ezingavuthiwe, isilinganiso singu-8-15, Umsebenzisi ukhetha isilinganiso sokucindezela sokufa, futhi ulungisa isilinganiso esithile sokucindezela, njengokukhetha isilinganiso esiphansi sokucindezela, esizuzisa ukwandisa okukhiphayo, ukunciphisa ukusetshenziswa kwamandla, ukunciphisa ukugqoka kwesikhunta sendandatho, kodwa futhi kunciphise izinga lezinhlayiya, njengama-pellets aqinile ngokwanele, ukubukeka kukhululekile futhi ubude buhlukile, futhi izinga le-powder liphezulu.

3.Izinga lokuvula lokufa kwendandatho

Izinga lokuvula le-pellet mill die yisilinganiso sendawo ephelele yembobo yokufa kuya endaweni ephelele ye-die. Ngokuvamile, izinga lokuvula liphezulu, isivuno sezinhlayiyana siphezulu. Ngaphansi kwesisekelo sokuqinisekisa amandla okufa, izinga lokuvula leringi lingathuthukiswa ngokusemandleni.

Kwezinye izinto zokusetshenziswa, ngaphansi kwesimo sesilinganiso sokucindezelwa okunengqondo, udonga lokufa kwe-pellet mill luncane kakhulu, ukuze amandla okufa akwanele, futhi umphumela wokuqhuma uzovela ekukhiqizeni. Ngalesi sikhathi, ukushuba kwedayizi lendandatho kufanele kwandiswe ngaphansi kwesisekelo sokuqinisekisa ubude obusebenzayo bomgodi wokufa.

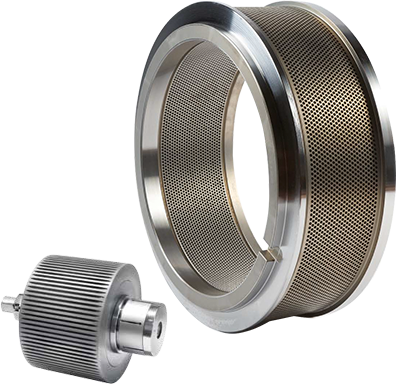

4.Ukumatanisa phakathi kwe-pellet mill die kanye ne-roller

Kuwubuchwepheshe obubaluleke kakhulu bokuthuthukisa ukusebenza kahle kwe-granulation kanye nokwelula impilo yokufa. Kufanele ifake izici ezi-4:

- Iringi entsha iyafa nge-roller entsha yokucindezela, gwema ukusebenzisa ngokweqile i-pressure roller.

- Ngokwemvelo yezinto zokwakha, izici zohlobo lomshini zokukhethwa kwezinhlobo ezahlukene ze-roller yokucindezela, ukuze kuzuzwe ukusebenza kahle kwe-extrusion phakathi kwe-die and roll.

- Isihluthulelo sokulingana kwegebe ukuzinza futhi isimiso siwukuthi: ngaphandle kokuthinta umthamo, zama ukuphumula.

- Lawula isivinini sokudla, lungisa isikhundla eside nesifushane sokudla kwe-scraper ukuze ulawule isikhundla sokudla, ukusatshalaliswa kwezingqimba zezinto.

5.I-Pellet Mill die process process

Izimbobo ze-ring die zidinga kakhulu ngokwemishini yokucubungula nokucubungula, futhi ngensimbi engagqwali, ukubhobolwa kwezibhamu okukhethekile kanye nemishini yokuhlanza ukushisa kwe-vacuum kuyadingeka ukuze kukhiqizwe indandatho efayo yekhwalithi ephezulu. Inqubo enhle kakhulu yokuvala i-vacuum yokushisa ephezulu ingathuthukisa kakhulu ukuqina, ukuqina, ukumelana nokuhuzuka, amandla okukhathala kanye nokuqina kwensimbi. Kodwa-ke, ikhono lokuqinisekisa ukuqina kokuqina okulinganayo kuyo yonke imbobo yokufa kudinga izinga eliphezulu lamakhono okucubungula nolwazi olude.

6.I-dies surface roughness yodonga lwangaphakathi lwembobo yokufa

Ubulukhuni bobuso buphinde bube yinkomba ebalulekile yekhwalithi yokufa kweringi. Ngokuvamile, inani elincane le-inner wall surface roughness lizokwenza ngcono ikhwalithi yokulingana, linciphise ukuguga futhi linwebe impilo yeringi, kodwa izindleko zokucubungula ukufa kwendandatho zizokhuphuka.

Ukuqina kwembobo yendandatho nakho kuthinta isilinganiso sokucindezela kanye nokwakheka kwezinhlayiya, kanye nokusebenza kahle kokukhiqiza. Esilinganisweni esifanayo sokuminyanisa ukufa kwendandatho, ukuncipha kwevelu yokumahhadla, kwehla ukumelana nokukhishwa kwamapulangwe noma okuphakelayo, ukukhishwa okubushelelezi, ikhwalithi yama-pellets akhiqizwayo iyanda kanye nokusebenza kahle kokukhiqiza. Ukucutshungulwa kahle kwembobo yembobo yendandatho kungaba ama-microns angu-0.8-1.6, ubuhwaqaqe bendandatho bucishe bube ngama-microns angu-0.8, umshini ofanele ezintweni ezilahlwayo, akukho ukugaya.