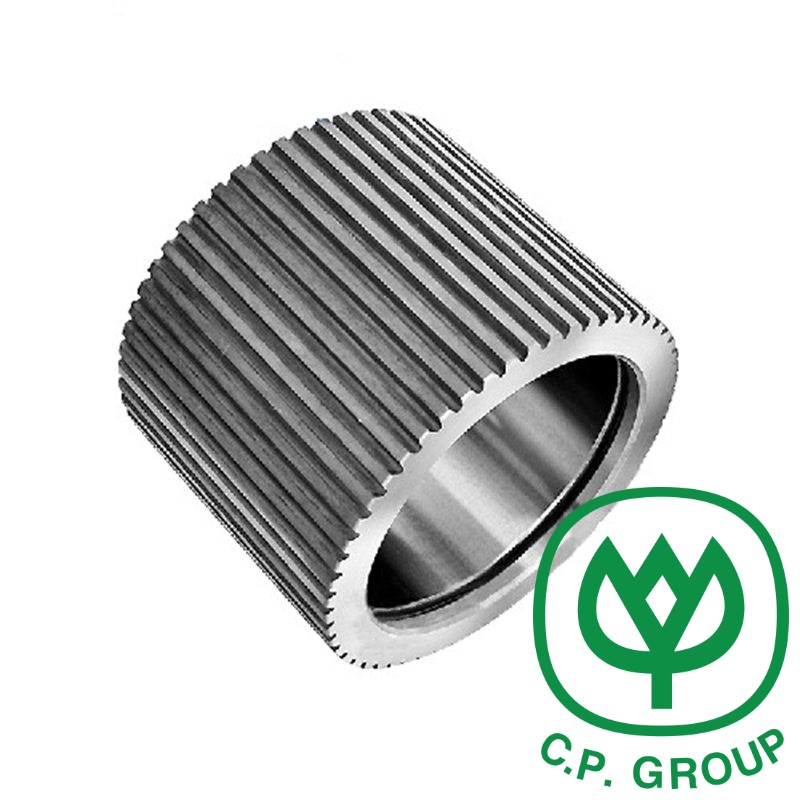

I-Corrugated Roller Shell - Vula ukuphela

- SHH.ZHENGYI

Uhlobo lwesiphetho esivulekile lusho ukuthi kunenqwaba yemigodi eqondile enezikhawu ezilinganayo endaweni eyindilinga yendawo engaphandle eyindilinga yegobolondo. Ama-grooves aqondile atholakala phakathi kwe-axial ye-surface circumferential yangaphandle yegobolondo le-roller yokucindezela, futhi ubude bawo bulingana nobubanzi begobolondo le-roller yokucindezela.

Izinzuzo:Ingadlala indima yokulinganisa izinto ekuqondeni komkhombe. Uma ingcindezi iphezulu kakhulu, ingadambisa ingcindezi kancane futhi inciphise ukuguga phakathi kwe-roller ne-ring die. Ikhoyili isebenza kahle futhi ukusebenza kuzinzile.

Ububi:Ukuvuza kwezinto kulula kuzo zombili iziphetho, okubangela ukulahlekelwa; ukugqokwa kweringi kuzobe kungalingani.

Igobolondo le-roller lingenye yezingxenye eziyinhloko zokusebenza ze-pellet mill. Isetshenziselwa ukucubungula ama-pellets ahlukahlukene e-biofuel, ukudla kwezilwane namanye ama-pellets. Isebenzisa i-alloy steel eqinile engagugi (20MnCr5), ukwelashwa kokushisa kwe-carburizing, ubulukhuni obufanayo. Impilo yesevisi yinde, futhi kunezinhlobo ezahlukene zezakhiwo ezifana nokumise okwezinyo, okuvimbekile okumise okwezinyo, nokumise okwembobo. Ingxenye ye-roller ecindezelayo yenziwe nge-eccentric shaft yangaphakathi nezinye izingxenye ezinobukhulu obunembile, okulula ukulungisa ibanga phakathi kwe-roller ecindezelayo kanye nokufa kwendandatho ngokuya ngezidingo zokukhiqiza komsebenzisi, futhi kulula ukugoqa nokuyifaka, futhi kulula ukufaka esikhundleni igobolondo roller ngokucindezela.

Izinyathelo zokuzivikela:

1. Khetha kahle isilinganiso esifanele sokucindezelwa kwembobo yokufa;

2. Lungisa kahle igebe elisebenzayo phakathi kweringi kanye nerola yokucindezela ukuze libe phakathi kuka-0.1 no-0.3mm (i-rola yokucindezela ishayelwa ukufa kweringi ngemva kokuba i-granulator entsha ivulwe esimweni “esifana nokuzungeza kodwa esingazungezi”) ;

3. I-ring entsha kufanele isetshenziswe ne-rola yokucindezela entsha, futhi i-pressure roller kanye ne-ring die kufanele ikhululeke ngaphambili bese iqiniswa. Uma amakhona abukhali avela ezinhlangothini zombili ze-roller yokucindezela, i-flange ye-roller yokucindezela kufanele ihanjiswe nge-grinder yesandla ngesikhathi ukuze kube lula ukulingana okuhle phakathi kwe-roller yokucindezela kanye nokufa kwendandatho;

4. Impahla eluhlaza kufanele ihlanzwe kuqala futhi ihlukaniswe kazibuthe ngaphambi kwe-pelletizer ukuze kuncishiswe ukucindezelwa kwensimbi embobeni yokufa. Nokuhlola imbobo yokufa njalo ukuze ubone ukuthi akukho yini ukuvaleka. Khipha noma ubhoboze imbobo yesikhunta evinjiwe ngesikhathi;

5. Ukuguqulwa kwePlastiki kwembobo yekhoni yomhlahlandlela ye-ring die kufanele kulungiswe. Lapho kulungiswa, kufanele kuqashelwe ukuthi ingxenye ephansi kakhulu yendawo engaphakathi yokusebenza yendandatho efayo kufanele ibe ngu-2mm ngaphezu kwephansi le-groove ye-overtravel, futhi kusekhona indawo yokulungisa i-shaft eccentric ye-roller yokucindezela ngemva kokulungiswa Uma kungenjalo, indandatho kufanele ilahlwe;

6. Igobolondo le-roller yokucindezela lenziwe ngezinto ze-alloy ezingagugi ngokucubungula igolide nokwelashwa kokushisa. Ifomu elingaphezulu kwezinyo legobolondo le-roller yokucindezela linethonya elithile ekusebenzeni kwe-granulation.