Umkhiqizi wamanani angcono kakhulu we-Closed tooth Roller Shell

- SHH.ZHENGYI

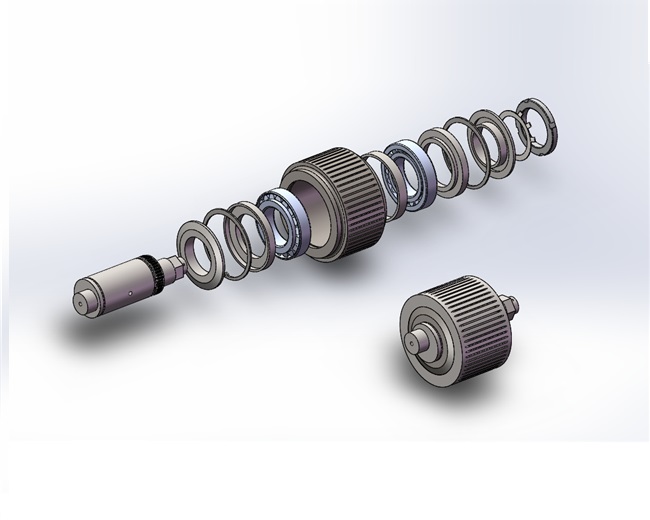

Igobolondo le-roller lingenye yezingxenye eziyinhloko zokusebenza ze-pellet mill. Isetshenziselwa ukucubungula ama-pellets ahlukahlukene e-biofuel, ukudla kwezilwane namanye ama-pellets. Isebenzisa i-alloy steel eqinile engagugi (40Cr, 20Crmnti, Gcr15), ukwelashwa kokushisa kwe-carburizing, ubulukhuni obufanayo. Impilo yesevisi yinde, futhi kunezinhlobo ezahlukene zezakhiwo ezifana nokumise okwezinyo, okuvimbekile okumise okwezinyo, nokumise okwembobo. Ingxenye ye-roller ecindezelayo yenziwe nge-eccentric shaft yangaphakathi nezinye izingxenye ezinobukhulu obunembile, okulula ukulungisa ibanga phakathi kwe-roller ecindezelayo kanye nokufa kwendandatho ngokuya ngezidingo zokukhiqiza komsebenzisi, futhi kulula ukugoqa nokuyifaka, futhi kulula ukufaka esikhundleni igobolondo roller ngokucindezela.

Igobolondo le-roller lingenye yezingxenye eziyinhloko zokusebenza ze-pellet mill. Isetshenziselwa ukucubungula ama-pellets ahlukahlukene e-biofuel, ukudla kwezilwane namanye ama-pellets. Isebenzisa i-alloy steel eqinile engagugi (40Cr, 20Crmnti, Gcr15), ukwelashwa kokushisa kwe-carburizing, ubulukhuni obufanayo. Impilo yesevisi yinde, futhi kunezinhlobo ezahlukene zezakhiwo ezifana nokumise okwezinyo, okuvimbekile okumise okwezinyo, nokumise okwembobo. Ingxenye ye-roller ecindezelayo yenziwe nge-eccentric shaft yangaphakathi nezinye izingxenye ezinobukhulu obunembile, okulula ukulungisa ibanga phakathi kwe-roller ecindezelayo kanye nokufa kwendandatho ngokuya ngezidingo zokukhiqiza komsebenzisi, futhi kulula ukugoqa nokuyifaka, futhi kulula ukufaka esikhundleni igobolondo roller ngokucindezela.

Izinyathelo zokuzivikela

1.Khetha kahle isilinganiso esifanele sokuminyanisa imbobo yokufa.

2.Lungisa kahle igebe lokusebenza phakathi kweringi kanye nerola yokucindezela ukuze libe phakathi kuka-0.1 no-0.3mm (i-rola yokucindezela ishayelwa ukufa kweringi ngemva kokuba i-granulator entsha ivuliwe esimweni "esifana nokuzungeza kodwa esingazungezi").

3.Iringi entsha kufanele isetshenziswe nerola yokucindezela entsha, futhi i-pressure roller kanye ne-ring die kufanele ikhululeke ngaphambi kwalokho bese iqiniswa. Uma amakhona abukhali avela ezinhlangothini zombili ze-roller yokucindezela, i-flange ye-roller yokucindezela kufanele ibe bushelelezi nge-grinder yesandla ngesikhathi ukuze kube lula ukulingana okuhle phakathi kwe-roller yokucindezela kanye nokufa kwendandatho.

4.Impahla eluhlaza kufanele ihlanzwe kuqala futhi ihlukaniswe kazibuthe ngaphambi kwe-pelletizer ukuze kuncishiswe ukucindezelwa kwensimbi embobeni yokufa. Nokuhlola imbobo yokufa njalo ukuze ubone ukuthi akukho yini ukuvaleka. Phuma noma ubhoboze imbobo yesikhunta evinjiwe ngesikhathi.

5.I-deformation yepulasitiki yembobo yekhoni yomhlahlandlela ye-ring die kufanele ilungiswe. Lapho kulungiswa, kufanele kuqashelwe ukuthi ingxenye ephansi kakhulu yendawo engaphakathi yokusebenza yendandatho efayo kufanele ibe ngu-2mm ngaphezu kwephansi le-groove ye-overtravel, futhi kusekhona indawo yokulungisa i-shaft eccentric ye-roller yokucindezela ngemva kokulungiswa Uma kungenjalo, indandatho kufanele ichithwe.

6.Igobolondo le-roller ye-pressure lenziwe ngezinto ze-alloy ezingagugi ngokucubungula igolide nokwelashwa kokushisa. Ifomu elingaphezulu kwezinyo legobolondo le-roller yokucindezela linethonya elithile ekusebenzeni kwe-granulation.

Iphrofayili yezinyo legobolondo elivame ukusetshenziswa: iphrofayili yezinyo ngohlobo, iphrofayili yezinyo hhayi ngohlobo, uhlobo lwembobo.

1.Ama-Pass and tooth groove rollers asetshenziswa kakhulu ekugayeni imfuyo nezinkukhu. Inzuzo yama-pass rollers ukuthi i-ring die igqoka ngokulinganayo, kodwa ukusebenza kwekhoyili kubi.

2.Irola yokucindezela komumo we-toove groove inokusebenza okuhle kwekhoyili futhi ivame ukusetshenziswa ezimbonini eziphakelayo, kodwa ukuguga kweringi akufani. Irola yokucindezela yomumo we-toove groove enonqenqema oluvalekayo ifaneleka kakhulu ukugaywa kwezinto zasemanzini. Shelelisela nhlangothi zombili.