Ubulukhuni be-particle sesinye sezibonakaliso ezisemgangathweni ukuba inkampani nganye yokutya ihlawula ingqalelo enkulu. Kukutya kwemfuyo kunye neenkukhu, ubulukhuni obuphezulu buyakwenza ukuba incasa ingabinancancisi, kucutheke ukutya okutyiwayo, kwaye kubangele nezilonda emlonyeni kwiihagu ezincancisayo. Nangona kunjalo, ukuba ubunzima buphantsi, umxholo we powder uya kuncipha. Ukonyuka, ngakumbi ubulukhuni obuphantsi bemathiriyeli ye-pellet kuya kubangela iimeko ezingathandekiyo zomgangatho onjengokuhlela ukutya. Ke ngoko, amashishini kufuneka aqinisekise ukuba ubunzima bokutya budibana nemigangatho yomgangatho. Ukongeza ekulungiseni ifomyula yokutya, baphinde bagxininise kwiinqanaba ezahlukeneyo zemveliso kunye nenkqubo yokucubungula, eya kuba nefuthe elibalulekileyo kubulukhuni be-pellet feed.

I-1) Into edlala indima ebalulekileyo ekuqineni kweengqungquthela kwinkqubo yokugaya i-particle yokugaya ubukhulu bezinto eziluhlaza. Ngokuqhelekileyo, ukucotha ubukhulu beqhekeza lezinto eziluhlaza, kulula ukuba isitashi sibe ne-gelatin ngexesha lenkqubo yokulungelelanisa, kwaye inamandla ngakumbi impembelelo yokudibanisa kwiipellets. Okukhona ukwaphuka ngokulula, kokukhona ukuqina kokuqina. Ngoko ke, kwimveliso yokwenyani, ubungakanani bamasuntswana atyumzayo bufuna ukulungiswa ngokufanelekileyo ngokwemveliso yezilwanyana ezahlukeneyo kunye nobukhulu bomsesane wokufa.

2) Ngonyango lokukhukhumala kwezinto eziluhlaza, i-toxins kwizinto eziluhlaza zingasuswa, iibhaktheriya zingabulawa, izinto ezinobungozi zinokupheliswa, iiprotheyini ezikwizinto eziluhlaza ziyakwazi ukuchithwa, kwaye isitashi sinokugcwaliswa ngokupheleleyo. Okwangoku, imathiriyeli ekhukhumeleyo ekrwada isetyenziswa ikakhulu kwimveliso yokutya kwehagu encancisayo yodidi oluphezulu kunye nokutya okukhethekileyo kwemveliso yasemanzini. Kwiimveliso ezikhethekileyo zasemanzini, emva kokuba izinto eziluhlaza zikhukhumezekile, iqondo le-starch gelatinization liyanda kwaye ukuqina kweengqungquthela ezibunjiweyo kuyanda, okunenzuzo ekuphuculeni ukuzinza kwamaqhekeza emanzini. Ukutya kwehagu ezincancisayo, amasuntswana kufuneka abe crispy kwaye angaqini kakhulu, okuluncedo ekutyisweni kweehagu ezincancisayo. Nangona kunjalo, ngenxa yomgangatho ophezulu we-gelatinization yestatshi kwiipellets zehagu ezanyisayo ezikhukhumeleyo, ukuqina kweepellets zesondlo kukhulu kakhulu.

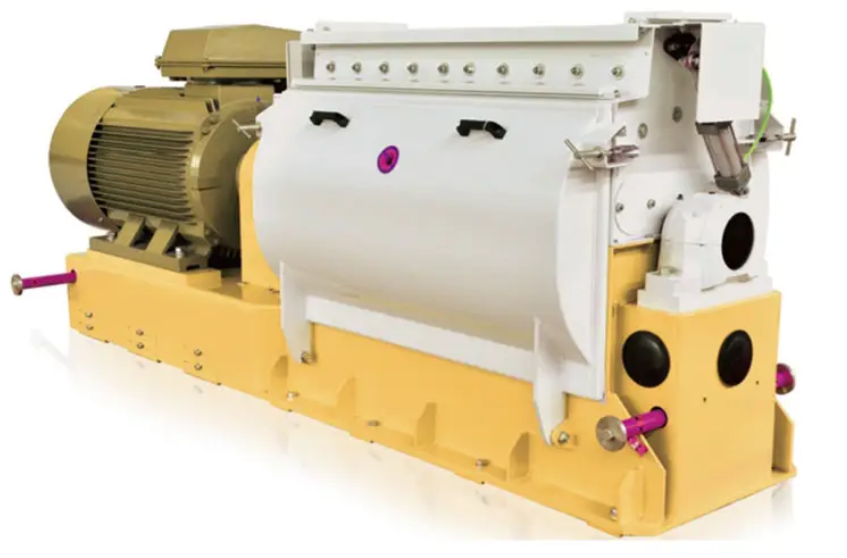

I-3) Ukuxuba izinto eziluhlaza kunokuphucula ukufana kwamacandelo ahlukeneyo obungakanani be-particle, eyinzuzo ekugcineni ubulukhuni be-particle ngokusisiseko kunye nokuphucula umgangatho wemveliso. Ekuveliseni ukutya okunzima kwepellet, ukongeza i-1% ukuya kwi-2% yomswakama kwi-mixer kuya kunceda ukuphucula ukuzinza kunye nobunzima bokutya kwe-pellet. Nangona kunjalo, kuyimfuneko ukuqwalasela imiphumo emibi yokunyuka komswakama ekomisweni nasekupholiseni iipelisi. Kananjalo ayihambisani nokugcinwa kwemveliso. Xa kuveliswa ukutya okumanzi kwepellet, ukufuma ukuya kutsho kuma 20% ukuya kuma 30% kungongezwa kumgubo. Kulula ukongeza malunga ne-10% yomswakama ngexesha lenkqubo yokuxuba kunokuba ngexesha lenkqubo yokumisa. Iipellet ezenziwe kwizinto ezinobumanzi obuphezulu zinobunzima obuphantsi, ukuthamba kunye nokuthandeka kakuhle. Amashishini amakhulu okufuya angasebenzisa le feed pellet imanzi. Iipellets ezimanzi azikho lula ukuzigcina kwaye zifunwa ukuba zondliwe ngoko nangoko emva kwemveliso. Ukongeza ioli ngexesha lenkqubo yokuxuba yinkqubo eqhelekileyo yokongeza ioli kwiindibano zocweyo zokuvelisa ukutya. Ukongeza i-1% ukuya kwi-2% yegrisi inefuthe elincinci ekunciphiseni ubulukhuni beengqungquthela, ngelixa ukongeza i-3% ukuya kwi-4% yegrisi kunokunciphisa kakhulu ubunzima beengqungquthela.

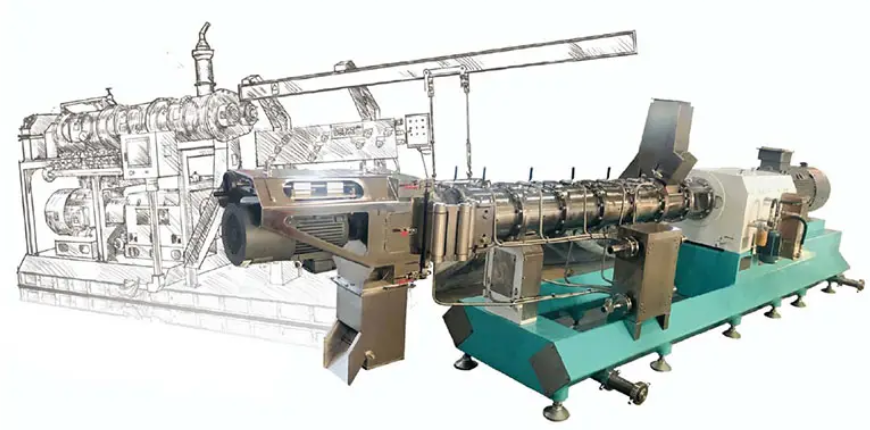

I-4) Ukulungiswa kwe-Steam yinkqubo ephambili kwi-pellet feed processing, kunye nefuthe le-conditioning lichaphazela ngqo isakhiwo sangaphakathi kunye nomgangatho wokubonakala kweepellets. Umgangatho we-Steam kunye nexesha lokumisa zizinto ezimbini ezibalulekileyo ezichaphazela umphumo wokulungisa. Umgangatho ophezulu owomileyo kunye nomphunga ogcweleyo unokubonelela ngobushushu obuninzi ukunyusa ubushushu bezinto kunye ne-gelatinize isitashi. I-conditioning ixesha elide, iqondo eliphezulu le-starch gelatinization. Ixabiso eliphezulu, i-denser isakhiwo se-particle emva kokwenza, ngcono ukuzinza, kunye nobunzima obukhulu. Ukutya kweentlanzi, i-double-layer okanye i-multi-layer jackets zisetyenziselwa ukulungelelanisa ukunyusa izinga lokushisa kunye nokwandisa ixesha lokulungisa. Kukulungele ngakumbi ekuphuculeni ukuzinza kweentlanzi zentlanzi emanzini, kwaye ubunzima beengqungquthela buye banda ngokufanelekileyo.

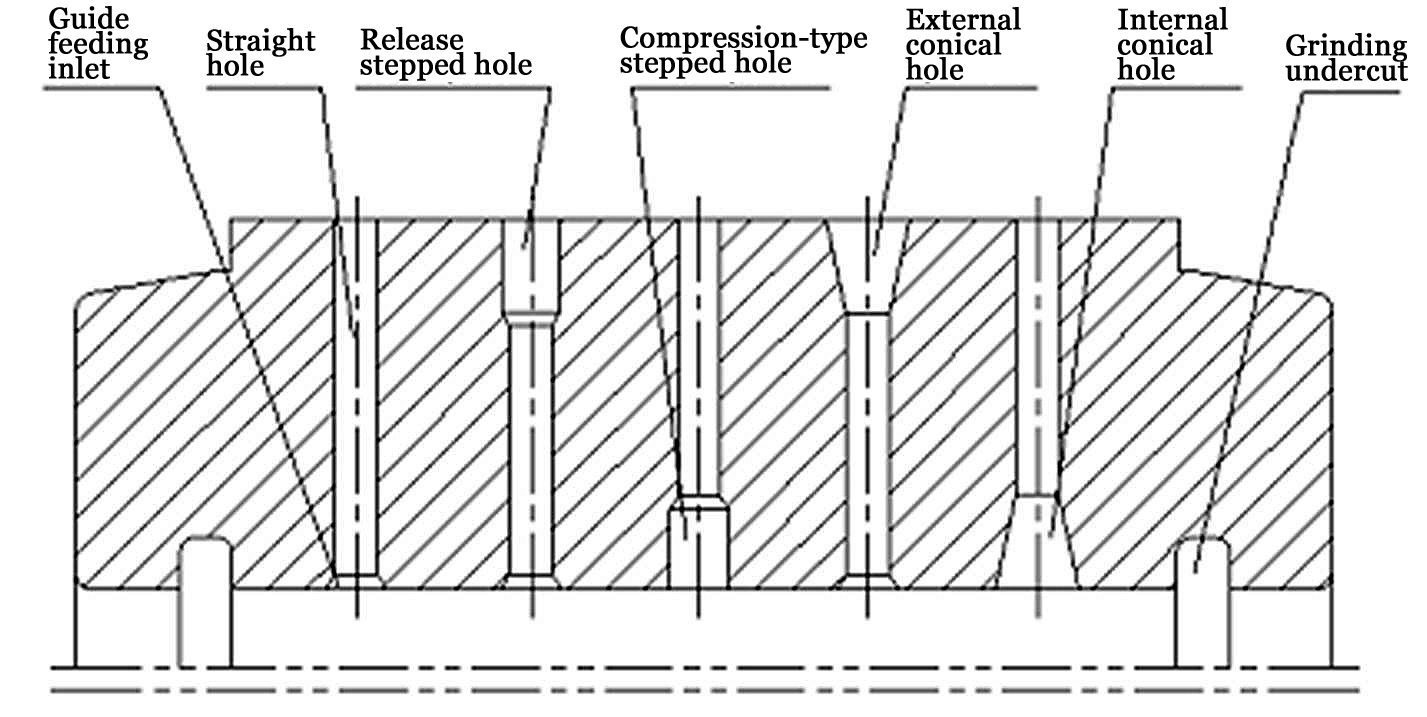

I-5) Ngethuba lenkqubo ye-granulation, iiparitha zobuchwepheshe ezifana ne-aperture kunye ne-compression ratio ye-ring ring iya kuchaphazela ubunzima beengqungquthela. Ubunzima beengqungquthela ezenziwe ngama-ring molds kunye ne-aperture efanayo kodwa i-compression ratios eyahlukeneyo iya kwanda kakhulu ngokunyuka komlinganiselo wokunyanzeliswa. . Ukukhetha umsesane wokufa ngomlinganiselo ofanelekileyo woxinzelelo kunokuvelisa amasuntswana anobulukhuni obufanelekileyo. Ngelo xesha, ubude beengqungquthela bubuye bube nefuthe elibalulekileyo kumandla okunyamezela uxinzelelo. Ngamasuntswana obubanzi obufanayo, ukuba amasuntswana angenaziphene, ubude bamasuntswana ubude, bukhulu ubunzima obulinganisiweyo. Ngoko ke, ukulungelelanisa isikhundla somsiki ukugcina ubude obufanelekileyo beengqungquthela kunokugcina ubulukhuni beengqungquthela ngokusisiseko. I-particle diameter kunye ne-cross-sectional shape nayo inefuthe elithile kubulukhuni be-particle. Ukongezelela, izinto eziphathekayo zomsesane nazo zinempembelelo ethile kumgangatho wokubonakala kunye nobunzima beepellets. Kukho iiyantlukwano ezicacileyo phakathi kwe-pellet feed eveliswa yintsimbi eqhelekileyo efayo kunye nentsimbi engenasici iyafa.

Ukuze kwandiswe ixesha lokugcinwa kweemveliso zokutya kunye nokuqinisekisa umgangatho wemveliso kwixesha elithile, ukomisa okuyimfuneko kunye nokupholisa amasuntswana okutya kuyafuneka.