Ngokwe-International Food Industry Federation (IFIF), imveliso yonyaka yehlabathi yokutya okudityanisiweyo iqikelelwa ngaphezulu kweetoni zebhiliyoni enye kwaye imbuyekezo yonyaka yehlabathi yemveliso yokutya yorhwebo iqikelelwa ngaphezulu kweebhiliyoni ezingama-400 zeedola (iibhiliyoni ezingama-394 zeedola).

Abavelisi bezondlo abanakukwazi ukuhlawula ixesha lokuphumla elingacwangciswanga okanye ukulahleka kwemveliso ukuze bahambisane nemfuno ekhulayo. Kwinqanaba leplanti, oku kuthetha ukuba zombini izixhobo kunye neenkqubo kufuneka zizinzile ukuhlangabezana neemfuno ngelixa zigcina umgca osezantsi osempilweni.

Ukulula kokuzenzekelayo kubalulekile

Ubungcali buyehla kancinci njengoko abasebenzi abadala kunye nabanamava bethatha umhlala-phantsi kwaye abatshintshwa ngesantya esifunekayo. Ngenxa yoko, abasebenzi bomatshini bokutya abanezakhono baxabiseke kakhulu kwaye kukho imfuneko ekhulayo yokuzenzekelayo iinkqubo ngendlela enembile nelula, ukusuka kubaqhubi ukuya ekuphatheni nasekulawuleni imveliso. Ngokomzekelo, indlela yokwahlulahlula kwi-automation inokwenza kube nzima ukudibanisa kunye neenkqubo ezahlukeneyo ezivela kubathengisi abahlukeneyo, nto leyo ngokwayo inokudala imingeni engeyomfuneko, ekhokelela kwixesha elingacwangciswanga. Nangona kunjalo, iingxaki ezinxulumene neendawo ezisetyenzisiweyo (i-pellet mill, i-ring die, i-feed mill) ubukho kunye nekhono lenkonzo nako kunokukhokelela kwixesha elibiza kakhulu.

Oku kunokuphetshwa ngokulula ngokusebenzisana nomboneleli wesisombululo seshishini. Ngenxa yokuba ishishini lijongene nomthombo omnye wobuchule kuyo yonke imiba yomzi-mveliso kunye neenkqubo zayo ezinxulumeneyo kwakunye neemfuno ezifanelekileyo zolawulo. Kwisityalo sokutya kwezilwanyana, izinto ezinjengokudosa okuchanekileyo kwezongezo ezininzi, ulawulo lobushushu, ulawulo lokugcinwa kwemveliso kunye nokunciphisa inkunkuma ngokuhlanjwa kunokulawulwa ngokuchanekileyo, ngelixa kugcinwa elona nqanaba liphezulu lokhuseleko lokutya. Iimfuno zokhuseleko lokutya zinokufezekiswa. Ixabiso lesondlo. Oku kwandisa ukusebenza ngokubanzi kwaye ekugqibeleni ixabiso ngetoni nganye yemveliso. Ukwandisa imbuyekezo kutyalo-mali kunye nokunciphisa iindleko zizonke zobunini, inyathelo ngalinye kufuneka lilungelelaniswe nomsebenzi womntu ngamnye ngelixa uqinisekisa ukucaca okupheleleyo kwenkqubo.

Ukongeza, unxibelelwano olusondeleyo kunye nabaphathi beakhawunti abazinikeleyo, oomatshini kunye neenjineli zenkqubo ziqinisekisa ukuba amandla obugcisa kunye nokusebenza kwezisombululo zakho ezizenzekelayo zihlala zikhuselwe. Esi sixhobo sokulawula ngokupheleleyo inkqubo siqinisekisa imveliso esemgangathweni ophezulu kwaye yongeza ukulandelelwa okwakhiweyo kwizinto ezinyukayo kunye nezantsi xa kufuneka. Zonke iinkqubo zokuvelisa zixhaswa kwi-intanethi okanye kwisayithi, ukusuka ekulandeleni inkqubo yokulawula ukuqondisa inkxaso nge-Intanethi.

Ukwandisa ukufumaneka: inkxalabo engundoqo

Izisombululo zasefektri zinokuhlelwa njengayo nayiphi na into ukusuka kwisixhobo somatshini omnye ukuya eludongeni okanye kufakelo lwendawo eluhlaza, kodwa ugxininiso luyafana kungakhathaliseki ubungakanani beprojekthi. Oko kukuthi, indlela inkqubo, umgca okanye isityalo sonke esibonelela ngayo into efunekayo ukuvelisa iziphumo ezilungileyo. Impendulo ixhomekeke kwindlela izisombululo eziyilwe ngayo, ziphunyezwe kwaye ziphuculwe ukubonelela ngokufumaneka okuphezulu ngokweeparamitha ezimiselweyo. Imveliso yibhalansi phakathi kotyalo-mali kunye nenzuzo, kwaye imeko yeshishini sisiseko sokumisela ukuba yeyiphi inqanaba ekufuneka kufikelelwe kuyo. Zonke iinkcukacha ezichaphazela amanqanaba emveliso zingumngcipheko kwishishini lakho, kwaye sicebisa ngamandla ukuba ushiye i-bancing act kwiingcali.

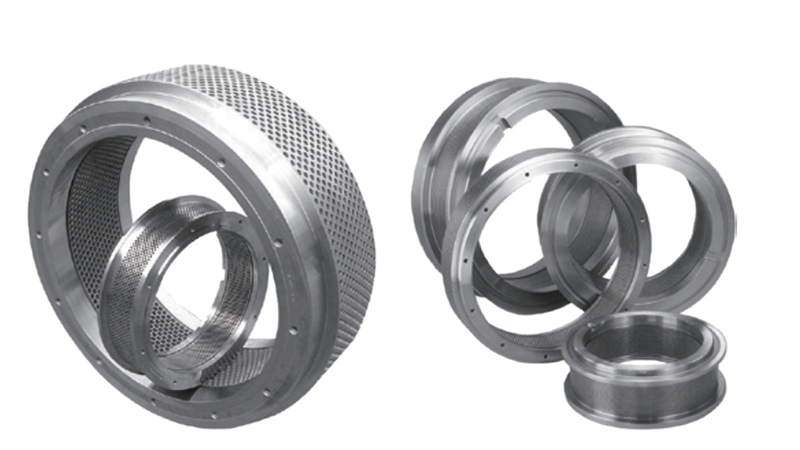

Ngokususa unxibelelwano oluyimfuneko phakathi kwababoneleli kunye nomboneleli wezisombululo zeshishini elinye, abanini bamashishini baneqabane elinoxanduva nelinoxanduva lokuphendula. Umzekelo, iifektri zifuna ukufumaneka kweendawo ezisetyenzisiweyo kunye nezinto ezinxitywayo ezinjengezando zeHammermill, izikrini, iRoller mill/Flaking mill rolls, Pellet mill dies, mill rolls kunye namalungu okusila njl njl. iingcali. Ukuba ungumboneleli wesisombululo sefektri, nokuba ezinye izinto zifuna umnikezeli weqela lesithathu, yonke inkqubo inokukhutshelwa ngaphandle.

Emva koko sebenzisa olu lwazi kwiindawo ezibalulekileyo ezifana nokubikezela. Ukwazi xa inkqubo yakho ifuna ukugcinwa kubalulekile ekunciphiseni ixesha lokuphumla kunye nokwandisa imveliso. Ngokomzekelo, i-pellet mill idla ngokusebenza kwi-24/7 isiseko, ngoko oku kubalulekile ekusebenzeni kwabo ngempumelelo. Izisombululo ezikhoyo kwimarike namhlanje zibeke iliso kwaye zikhulise ukusebenza ngexesha langempela, zikhokela izinto ezifana nokungcangcazela kwaye zilumkise abaqhubi ngexesha lokungasebenzi kakuhle okunokwenzeka ukuze bacwangcise ixesha lokuphumla ngokufanelekileyo. Ehlabathini elifanelekileyo, ixesha lokuphumla liya kuhla kwiincwadi zembali, kodwa ngokwenene kunjalo. Umbuzo ngowokuba kwenzeka ntoni xa oko kusenzeka. Ukuba impendulo ayisiyiyo "iqabane lethu lesisombululo sefektri sele liyisombulule le ngxaki", mhlawumbi lixesha lotshintsho.