Kweli xesha lanamhlanje, imfuneko yokutya kwezilwanyana iye yanda. Njengokuba imfuno yemveliso yemfuyo isanda, iifeed Mills zidlala indima ebalulekileyo ekuhlangabezaneni nezi mfuno. Nangona kunjalo, iifeed Mills zihlala zijongana nomngeni wokugcina kunye nokulungisa ii-ring dies, eziyinxalenye ebalulekileyo yokuvelisa iipellet zesondlo ezikumgangatho ophezulu.

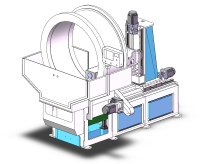

Ukuze ucombulule ezi ngxaki, isisombululo sokusika siye savela kumatshini wokulungisa umsesane wokufa. Esi sixhobo esitsha sinikezela ngokusebenza okubanzi okwenzelwe ukulungiswa kweringi kwiifedi zokusila.

– Ukucoca imingxunya. Iyakwazi ukususa ngokufanelekileyo izinto ezishiyekileyo kumngxuma wokufa weringi. Ngokuhamba kwexesha, umsesane uyafa unokuvaleka okanye uvaleleke, uthintele inkqubo yokuvelisa. Ngomsebenzi wokucoca umngxuma, umatshini wokuhlaziya unokususa ngokulula nayiphi na inkunkuma okanye izithintelo kwimingxunya yokufa kweringi. Oku akugcini nje ukwandisa izinga lemveliso yeepellet, kodwa kunciphisa umngcipheko wexesha lokunciphisa ngenxa yokuvala rhoqo.

- imingxuma Chamfering. Ikwagqwesa kwi-chamfering yomngxuma. I-Chamfering yinkqubo yokugudisa kunye ne-chamfering ekupheleni komngxuma kwi-ring die. Olu phawu lunyusa ukuqina kunye nobomi beringi, oko kwenza ukuba iifeed Mills zikwazi ukonga iindleko zokutshintsha ekuhambeni kwexesha.

- Ukusila umphezulu wangaphakathi weringi. Lo matshini unako nokusila umphezulu wangaphakathi wokufa kweringi. Ngokusebenzisa iindlela ezichanekileyo zokusila, umatshini unokulungisa nakuphi na ukungahambi kakuhle kwendawo okanye umonakalo kwi-ring die. Oku kuqinisekisa ukuba iipellet ziveliswa ngowona mgangatho uchanekileyo, ukuphucula umgangatho wesondlo kunye nempilo yezilwanyana iyonke.