ICANDELO 1: UKUHLOLWA PHAMBI KOKUFAKIWA

1. Ukuhlolwa kweringi phambi koFakelo

Nokuba umphezulu wokusebenza ulungelelene.

Ingaba i-groove igugile, kunye nokuba umngxuma owenziwe ngentambo waphukile.

Nokuba i-Dia hole kunye neCompression ratio ichanekile

Nokuba kukho ukubola okanye ukunxitywa kwamanqaku kwihupula kunye nomphezulu obhityileyo, njengoko kubonisiwe kumfanekiso 1 no-2.

2. Ukuhlolwa kweRoller Phambi koFakelo

Ingaba ukujikeleza kwecandelo kuqhelekileyo

Ingaba umphetho we-roller ugugile

Ingaba imilo yezinyo iphelele

3. Qwalasela imeko yokunxitywa kwehupula, kwaye ubuyisele ihupula engasebenziyo ngexesha

4. Qwalasela ukunxitywa komphezulu onyukayo werim yedrive, kwaye ubuyisele i rim yedrive engaphumelelanga ngexesha

5. Khangela kwaye ulungise i-angle ye-scraper ukuze ugweme ukusasazeka kokungalingani kwezinto

6. Ingaba umngxuma wofakelo lwekhowuni yokutya yonakele okanye cha

INXALENYE 2: IIMFUNO ZOKUFAKWA KWE-RING DIE

1. Qinisa onke amandongomane kunye neebholiti ngokulinganayo kwitorque efunekayo

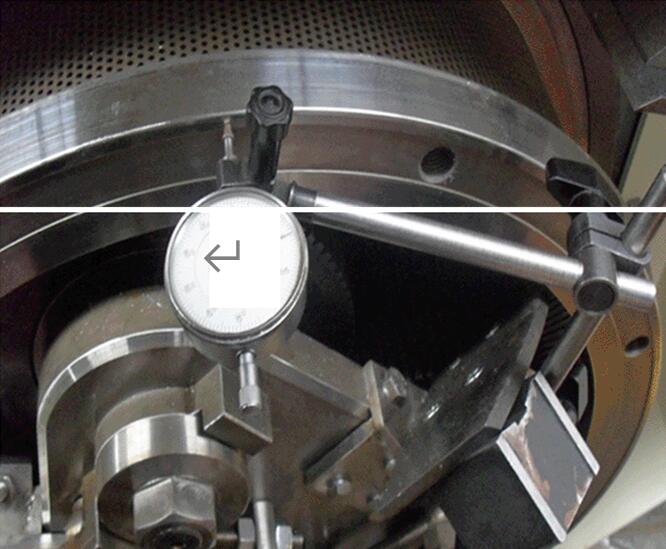

-SZ LH SSOX 1 70 (imodeli ye-600) njengomzekelo, i-torque yokutshixa i-ring 30 0 N. m, Fengshang-SZ LH535 X1 90 granulator ephethe ibhokisi yebholiti yokuqinisa i-torque 470N.m), i-torque wrench njengoko kubonisiwe kuMfanekiso 3 ; xa i-cone ring die ifakwe, isiphelo sobuso bomnxeba kufuneka sigcinwe ngaphakathi kwe-0.20 mm, njengoko kubonisiwe kwi-Figure 4.

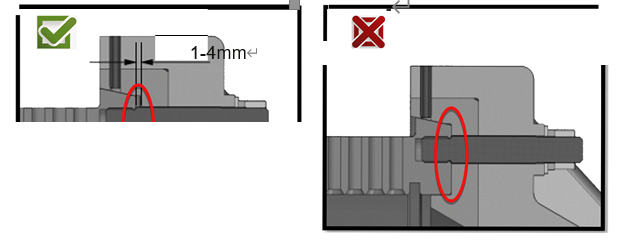

2. Xa i-cone ring die efakwe, ukucocwa phakathi kobuso bokugqibela bomsesane kuyafa kunye nobuso besiphelo se-flange yevili lokuqhuba ngu-1-4mm, njengoko kubonisiwe kuMfanekiso 5, ukuba imvume incinci kakhulu okanye ayikho. Ukukhutshwa, i-rim ye-drive kufuneka itshintshwe, kungenjalo iibholiti zokuqinisa zinokwaphuka okanye i-ring die inokophuka.

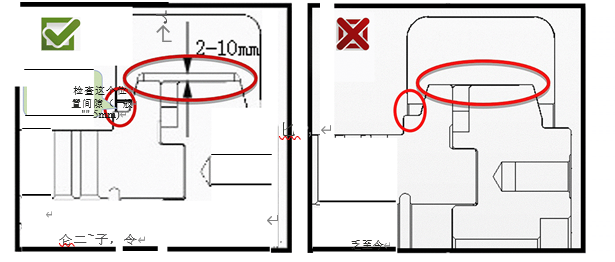

3. Xa ufaka i-hoop ring die, tshixa onke amantongomane kunye neebholiti ngokwe-symmetrically ngokwetorque efunekayo, kwaye uqinisekise ukuba izikhewu phakathi kwebhokisi yokubamba nganye ziyalingana ngexesha lokutshixa. Sebenzisa igeyiji yokulinganisa ukulinganisa umsantsa phakathi komphezulu ongaphakathi ongaphantsi webhokisi kunye nomphandle ongaphandle weringi yebhokisi yokubamba ibhokisi (ngokuqhelekileyo yi-2-10mm). Njengoko kuboniswe kwi-Figure 6, ukuba i-gap incinci kakhulu okanye ayikho i-gap, ibhokisi yokubamba kufuneka ithathelwe indawo.

4. I-gap ye-die rolling kufuneka ibe phakathi kwe-0.1-0.3 mm, kwaye ukulungiswa kunokwenziwa ngokuhlolwa okubonakalayo. Xa i-ring difa ijikeleza, kungcono ukuba i-rolling ayijikelezi. Xa kufa entsha kusetyenziswa, ingakumbi xa umsesane die kunye umngxuma encinane die isetyenziswa, i gap die rolling ngokuqhelekileyo kwandiswe ukugqiba ukubaleka-kwixesha lokufa ukuqengqeleka kwaye uphephe isenzeko calendering of ring die intsimbi umlomo.

5. Emva kokuba i-ring ring die ifakwe, khangela ukuba i-roller igxininisekile

INXALENYE 3: I-RING DIE UKUGCINWA KUNYE NOLONDOLOZO

1. Idayi yeringi kufuneka igcinwe kwindawo eyomileyo necocekileyo kwaye imakishwe neenkcukacha.

2. Ukufa kwendandatho engasetyenziswanga ixesha elide, kucetyiswa ukuba ugqoke umphezulu kunye noluhlu lweoli ye-anti-rust.

3. Ukuba umngxuma wokufa wendandatho yokufa uvalwe yizinto eziphathekayo, nceda usebenzise indlela yokucwiliswa kweoli okanye ukupheka ukuthambisa izinto, uze uphinde uphinde uhlambuluke.

4. Xa umsesane ufile ugcinwe ngaphezu kweenyanga ezi-6, ioli ngaphakathi kufuneka izaliswe.

5. Emva kokuba idayi yeringi isetyenziselwe ixesha elithile, jonga rhoqo ukuba kukho iiprotrusions zengingqi kumphezulu ongaphakathi weringi, kwaye ujonge ukuba izibuko lomngxuma wokufa liphantsi, litywinwe okanye lijikelwe ngaphakathi, njengoko kubonisiwe. kwi-Figure 8. Ukuba ifunyenwe, i-ring ring ilungiswa ukuze ikhulise ubomi benkonzo, njengoko kuboniswe kuMzobo 9. Xa kulungiswa, kufuneka kuqatshelwe ukuba inxalenye ephantsi yendawo yangaphakathi yokusebenza yendandatho. Ukufa kufuneka kube yi-2 mm ngaphezu komzantsi we-groove ye-overtravel, kwaye kusekho isibonelelo sokulungelelaniswa kwe-rolling eccentric shaft emva kokulungiswa.