Idayi licandelo eliphambili kwilitye lokusila. Kwaye sisitshixoukwenza iipelisi zokutya. Ngokwezibalo ezingaphelelanga, iindleko ze-pellet mill die loss loss accounts ezingaphezu kwe-25% yeendleko zokugcinwa kweworkshop yemveliso yonke. Kuzo zonke iipesenti zokunyuka kweentlawulo, ukukhuphisana kwakho kwimarike kwehla nge-0.25%. Ngoko iinkcukacha ze-pellet mill zibaluleke kakhulu.

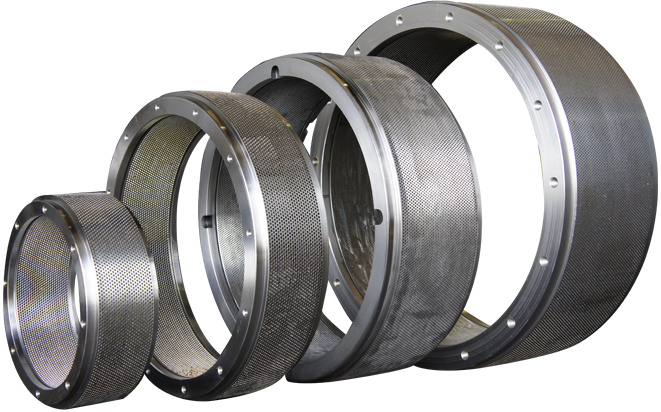

UShanghai Zhengyi (CPSHZY) yingcalifeed pellet yokusilaumthengisi eTshayina. Sinikezela ngeringi yokusila i-pellet, i-flat die pellet mill kunye neiindawo zokusila pellet, ezifana nokufa kweflethi, i-ring die, i-pellet mill roller, kunye nezinye iindawo zomatshini we-pellet.

1.Izinto zokusila zePellet

I-pellet mill die ngokuqhelekileyo yenziwe ngentsimbi ye-carbon, i-alloy structural steel okanye insimbi engenasici ngokusebenzisa i-forging, machining, imingxuma yokugrumba, kunye neenkqubo zokunyanga ubushushu. Umsebenzisi unokukhetha ngokwe-corrosion ye-particle ye-raw material. Izinto zokusila i-pellet kufuneka zenziwe nge-alloy structure yentsimbi okanye i-stainless steel ring mold.

I-Carbon structural iron, efana nentsimbi engama-45, ubulukhuni bayo bonyango lobushushu ngokuqhelekileyo yi-45-50 HRC, yinto ephantsi yomgangatho wokufa weringi, ukuxhathisa ukunxiba kunye nokumelana nomhlwa akubi, ngoku kupheliswe ngokusisiseko.

I-alloy structural steel, efana ne-40Cr, 35CrMo, njl., Ngobunzima bonyango lokushisa ngaphezu kwe-50HRC kunye neempawu ezintle ezidibeneyo zomatshini. I-die eyenziwe yale nto inamandla amakhulu kunye nokumelana nokugqoka, kodwa ukungahambi kakuhle kukuba ukuxhatshazwa kwe-corrosion akulungile, ngakumbi ukutya kweentlanzi.

Ixabiso lendandatho liyafa, elenziwe ngezinto eziphathekayo, i-marigold pellets, i-wood chips, i-straw pellets, njl., iphezulu kakhulu kunensimbi engenasici. Zombini i-20CrMnTi kunye ne-20MnCr5 zintsimbi ezisezantsi ze-carburizing alloy, zombini ziyafana, ngaphandle kokuba yangaphambili yintsimbi yaseTshayina kunye nentsimbi yokugqibela yaseJamani. Ekubeni i-Ti, i-chemical element, ayifane ifumaneke phesheya, i-20CrMnTi okanye i-20CrMn evela e-China isetyenziswa endaweni ye-20MnCr5 evela eJamani, ngoko ayingeni ngaphakathi kwendawo ye-alloy structural steel. Nangona kunjalo, uluhlu oluqinileyo lwale ntsimbi lunqunyelwe yinkqubo ye-carburizing ukuya kubunzulu obuphezulu be-1.2 mm, ekwayinzuzo yexabiso eliphantsi lale ntsimbi.

Izinto zensimbi ezingenasici ziquka i-German steel stainless steel X46Cr13, iChina i-4Cr13 intsimbi, njl. amaxabiso ngokwendalo aphezulu kuneentsimbi ze-carburized. Ngenxa yobomi obude bensimbi engenastainless die steel, i-frequency yokutshintshwa iphantsi kwaye ngoko ixabiso letoni liphantsi.

Ngokubanzi, imathiriyeli yokufa yeringi yokusila i-pellet yintsimbi yolwakhiwo lwentsimbi kunye nemathiriyeli yentsimbi.

2.Ukunyanzeliswa komlinganiselo we-pellet mill kufa

i=d/L

T=L+M

M bubunzulu bomngxuma oncitshisiweyo

ICompression ratio (i) ngumlinganiselo wedayamitha yomngxuma wokufa (d) kunye nobude obusebenzayo (L) bedayizi.

Ngokwendalo yemathiriyeli ekrwada, umlinganiselo yi-8-15, Umsebenzisi ukhetha umlinganiselo wokunyanzeliswa kwefa, kwaye ulungelelanisa umlinganiselo othile woxinzelelo, njengokukhetha umlinganiselo osezantsi kancinane woxinzelelo, onenzuzo ekwandiseni imveliso, ukunciphisa ukusetyenziswa kwamandla, ukunciphisa ukugqoka isikhunta sendandatho, kodwa kwakhona ukunciphisa umgangatho weengqungquthela, ezifana neepelisi azinamandla ngokwaneleyo, ukubonakala kukhululekile kwaye ubude buhluke, kwaye izinga le powder liphezulu.

3.Ukuvulwa izinga lokufa kweringi

Isantya sokuvula i-pellet mill die yi-ratio yendawo yonke ye-diye hole ukuya kwindawo esebenzayo epheleleyo yokufa. Ngokubanzi, inqanaba eliphezulu lokuvula i-die, liphezulu isivuno se-particle. Phantsi kwesiseko sokuqinisekisa amandla okufa, izinga lokuvula leringi lingaphuculwa kangangoko kunokwenzeka.

Kwezinye izinto eziluhlaza, phantsi kwemeko yomlinganiselo wokunyanzeliswa okufanelekileyo, udonga lokufa lwe-pellet luncinci kakhulu, ukuze amandla okufa akwanelanga, kwaye isiganeko sokufa kokuqhuma kuya kubonakala kwimveliso. Ngeli xesha, ubukhulu bomnxeba wokufa kufuneka bunyuswe phantsi kwesiseko sokuqinisekisa ubude obusebenzayo bomngxuma wokufa.

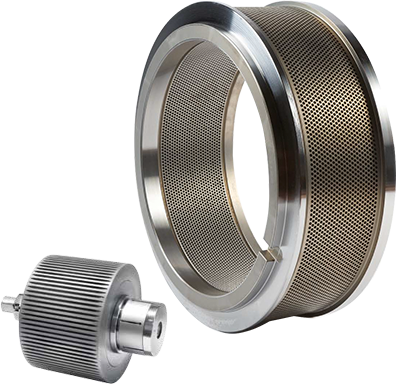

4.Ukuhambelana phakathi kwe-pellet mill die kunye ne-roller

Yeyona teknoloji ibalulekileyo yokuphucula ukusebenza kakuhle kwegranulation kunye nokwandisa ubomi bokufa. Kufuneka ibandakanye imiba emi-4:

- Umsesane omtsha uyafa kunye ne-roller entsha yoxinzelelo, kunqande ukusetyenziswa ngokugqithisileyo kwe-roller yoxinzelelo.

- Ngokobume bezinto eziphathekayo, iimpawu zohlobo lomatshini wokukhethwa kweendlela ezahlukeneyo ze-roller yoxinzelelo, ukwenzela ukuba kufezekiswe ukusebenza kakuhle kwe-extrusion phakathi kwe-die and roll.

- Isihluthulelo sokulungelelaniswa kwe-gap ukuzinza kwaye umgaqo uthi: ngaphandle kokuchaphazela amandla, zama ukuphumla.

- Ukulawula isantya sokutya, ukulungelelanisa ixesha elide kunye nelifutshane lokutya i-scraper ukulawula indawo yokutya, ukuhanjiswa kwezinto eziphathekayo.

5.I-Pellet mill die process process

Imingxunya yokufa yeringi ifuna kakhulu ngokwemigaqo yokulungiswa kunye nezixhobo zokusebenza, kunye nentsimbi engenasici, izixhobo zokudubula ezikhethekileyo kunye nezixhobo zokunyanga ubushushu bevacuum ziyafuneka ukuvelisa umgangatho ophezulu wokufa. Inkqubo yokucima i-vacuum ephezulu yokushisa inokuphucula kakhulu ukuqina, ukuqina, ukuxhathisa kwe-abrasion, amandla okudinwa kunye nokuqina kwentsimbi. Nangona kunjalo, ukukwazi ukuqinisekisa umaleko wobulukhuni olungeleleneyo kuwo wonke umngxuma wokufa kufuna umgangatho ophezulu wezakhono zokucwangcisa kunye namava amade.

6.Uburhabaxa bomphezulu wodonga lwangaphakathi lomngxuma wokufa

Uburhabaxa bomphezulu bukwasisalathisi esibalulekileyo somgangatho wokufa kweringi. Ngokubanzi, ixabiso elincinci le-rough yangaphakathi yodonga lomphezulu liya kuphucula umgangatho we-fit, ukunciphisa ukunxiba kunye nokwandisa ubomi bomsesane wokufa, kodwa iindleko zokucubungula ukufa kweringi ziya kwanda.

I-ring hole roughness iphinda ichaphazele umlinganiselo woxinzelelo kunye nokwenza amasuntswana, kunye nokusebenza kakuhle kwemveliso. Kwiringi efanayo kufa ucinezelo ratio, elisezantsi ixabiso uburhabaxa, isezantsi ukuxhathisa extrusion of chips iinkuni okanye ifidi, agudileyo ukukhutshwa, kokukhona umgangatho ophezulu iipellets eziveliswayo kwaye iphezulu ukusebenza kakuhle kwemveliso. Good ring die umngxuma processing inokuba ukuya ku 0.8-1.6 microns, ring die uburhabaxa malunga 0.8 microns, umatshini echanekileyo kwizinto ezilahlwayo, akukho kusila.