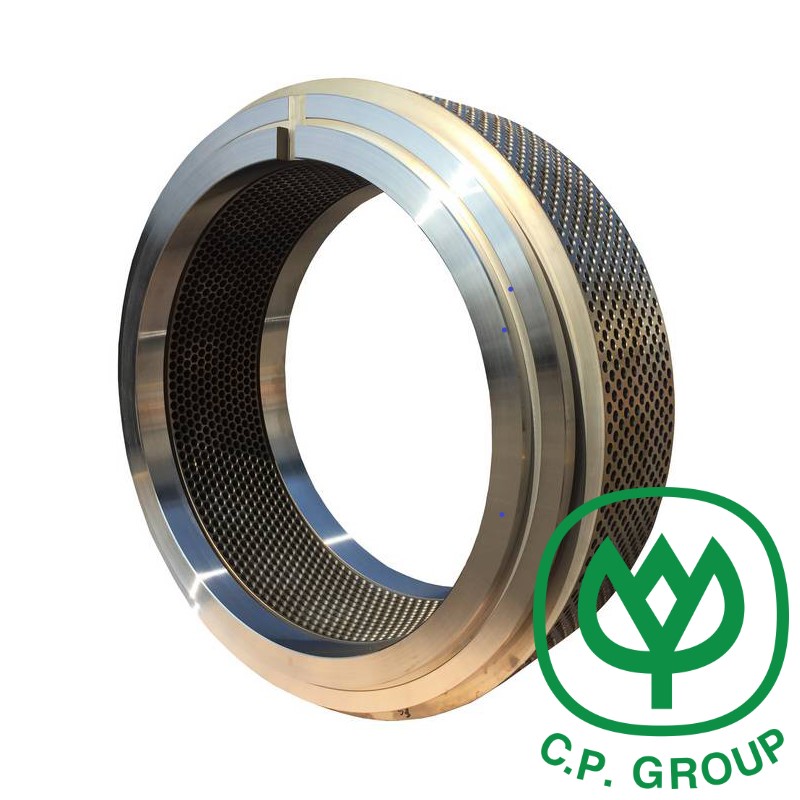

IDAH pellet cingcin paeh

- SHH.ZHENGYI

1.Select bahan baku kualitas luhur, steelmaking sekundér, degassing billet;

2.Ring bahan paeh: X46Cr13 / 4Cr13 (stainless steel), 42Crmo / 20CrMnTi (alloy steel) atawa bahan custom séjén;

3.Imported gun bor jeung multi-stasiun bor, hiji-waktos ngabentuk liang paeh, kualitas luhur finish, produksi feed, penampilan geulis tur kaluaran tinggi;

4.Select kombinasi tungku vakum sarta tungku quenching kontinyu pikeun mastikeun hirup layanan panjang;

5.According prinsip sarta sarat tina customer mendesain rasio komprési jeung kakuatan;

ujian 6.Microscopic pikeun mastikeun kualitas produk;

42Crmo / 20CrMnTi alloy steel ring téhnologi processing paeh:

Motong → Forging → Normalizing → Roughing → Tempering → Finishing → Pangeboran (Ngalegaan) Liang → Carburizing → grinding → (Kaasup Lapisan Oksidasi) → Tés Tekanan → (Passif Fosfor) → Coating Minyak Antirust → Pariksa jeung simpen pilihan;

X46Cr13 / 4Cr13 stainless steel ring téhnologi processing paeh:

Motong → Forging → Roughing → Normalizing → Finishing → Quenching na tempering → › Finishing → Liang pangeboran → Nitriding → Polishing → Test tekanan → Résistansi palapis → Minyak Rusty → Pariksa jeung simpen pilihan;

| S/N | Modél | Ukuran (mm) OD * ID * lebar sakabéh * lebar pad | Ukuran liang mm |

| 1 | IDAH51SA | 660*506*238*152 | 1-12 |

| 2 | IDAH53SA(PM-53SA) | 680*530*258*172 | 1-12 |

| 3 | IDAH53F(PM-53F) | 680*530*278*192 | 1-12 |

| 4 | IDAH635SA | 770*635*266*192 | 1-12 |