SZLH letoto la pellet leloala lesale shoa

- SHH.ZHENGYI

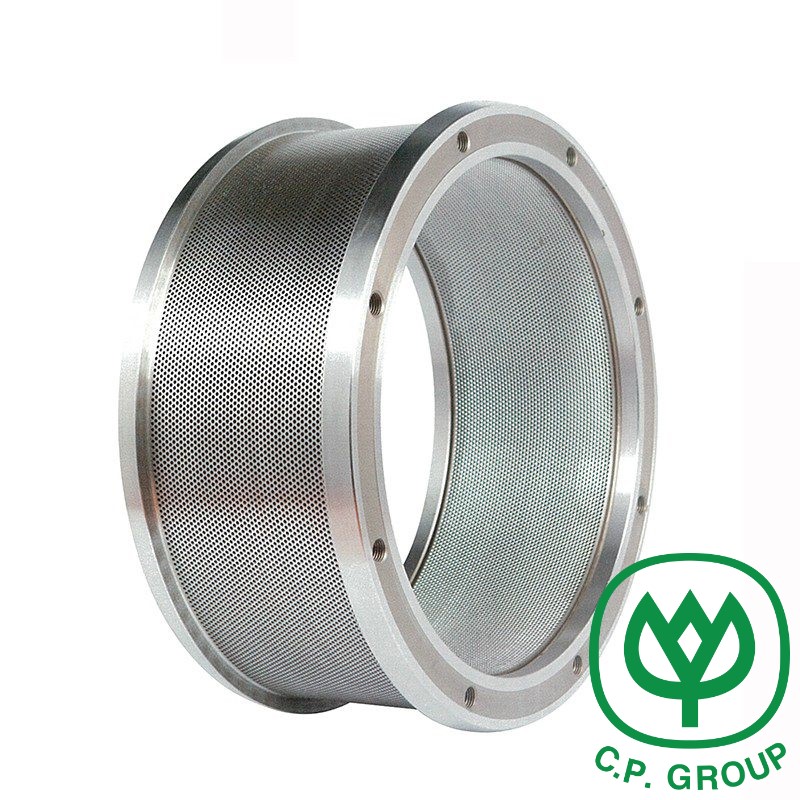

1.Khetha lisebelisoa tse tala tsa boleng bo holimo, ho etsa tšepe ea bobeli, billet ea degassing;

2.Ring die material: X46Cr13 / 4Cr13 (tšepe e sa hloekang), 42Crmo / 20CrMnTi (tšepe ea alloy) kapa lisebelisoa tse ling tse tloaelehileng;

3.Imported gun drill le multi-station drill, nako e le 'ngoe ea ho etsa lesoba la die, qetello ea boleng bo phahameng, tlhahiso ea lijo, ponahalo e ntle le tlhahiso e phahameng;

4.Khetha motsoako oa sebōpi sa vacuum le sebōpi se sa khaotseng sa ho tima ho netefatsa bophelo bo bolelele ba tšebeletso;

5.Ho ea ka molao-motheo le litlhoko tsa moreki ho theha karo-karolelano ea khatello le matla;

Tlhahlobo ea 6.Microscopic ho netefatsa boleng ba sehlahisoa;

42Crmo / 20CrMnTi alloy alloy ring ring e sebetsanang le theknoloji:

Ho Seha→Ho Feta→Ho Tloaeleha→Ho Hlōla→Ho Belisa→Ho Felisa→Ho cheka (Ho Atolosa) Lekoti→Ho cheka →Ho Sila→(Ho sa kenyeletsoe Lera la Oxidation) →Teko ea Khatello→(Phosphorus Passivation)→Ho Abela Oli e Thibelang ho Ruta →Sheba le ho boloka likhetho;

X46Cr13 / 4Cr13 theknoloji ea tšepe e sa hloekang e shoang:

Ho seha→Ho Feta→Ho qhoqhoa→Ho tloaeleha→Ho phethela→Ho tima le ho futhumatsa → Ho phethela→Lesoba la ho cheka→Ho cheka →Ho hloekisetsa→Teko ea khatello → Ho hana ho penta→Oli e rusitseng→Sheba le ho boloka likhetho;

| S/N | Mohlala | Boholo OD * ID * bophara ka kakaretso * bophara ba pad -mm | Boholo ba lesoba mm |

| 1 | SZLH320 | 432*320*130*87 | 1-12 |

| 2 | SZLH350 | 500*350*180*100 | 1-12 |

| 3 | SZLH400 | 558*400*200*120 | 1-12 |

| 4 | SZLH400D | 558*400*218*138 | 1-12 |

| 5 | SZLH420 | 580*420*196*120 | 1-12 |

| 6 | SZLH420D | 580*420*214*140 | 1-12 |

| 7 | SZLH508 | 660*508*238*155 | 1-12 |

| 8 | SZLH508E | 660*508*284*185 | 1-12 |

| 9 | SZLH558 | 774*572*270*170 | 1-12 |

| 10 | SZLH578 | 774*572*300*200 | 1-12 |

| 11 | SZLH768 | 966*761*370*210 | 1-12 |

Khetla ea roller e hatetsoeng

Khetla ea rolara ke e 'ngoe ea likarolo tse ka sehloohong tse sebetsang tsa leloala la pellet. E sebelisoa ho sebetsana le li-pellets tse fapaneng tsa biofuel, lijo tsa liphoofolo le li-pellets tse ling. Ho sebelisa tšepe ea alloy e phahameng e sa sebetseng (40Cr, 20Crmnti, Gcr15), kalafo ea mocheso oa carburizing, boima ba junifomo. Bophelo ba ts'ebeletso bo bolelele, 'me ho na le mefuta e fapaneng ea meaho e kang leino le bōpehileng joaloka leino, le thibiloe ka sebōpeho sa leino, le sebopeho sa lesoba. Karolo e hatellang e entsoe ka shaft e ka hare ea eccentric le likarolo tse ling tse nang le litekanyo tse nepahetseng, tse loketseng ho lokisa sebaka se pakeng tsa rolara e hatellang le selikalikoe se shoang ho latela litlhoko tsa tlhahiso ea mosebelisi, 'me ho bonolo ho mena le ho kenya, mme ho bonolo ho nka sebaka sa khetla ea rolara e hatellang.

Mehato ya tlhokomelo:

1. Khetha ka nepo tekanyo ea compression ea lesoba le loketseng;

2. Lokisa ka nepo lekhalo la ho sebetsa pakeng tsa lesale la ho shoa le mochine oa khatello ho ba pakeng tsa 0.1 le 0.3mm (motlakase oa khatello o khannoa ke lesale le shoa ka mor'a hore granulator e ncha e buletsoe "e kang ho potoloha empa e sa potoloha" boemo) ;

3. Mochini o mocha oa lesale o lokela ho sebelisoa ka mochine o mocha oa khatello, 'me mochine oa khatello le lesale le lokela ho lokoloha pele ebe o tiisa. Ha likhutlo tse bohale li hlaha ka mahlakoreng a mabeli a khatello ea khatello, flange ea mochine oa khatello e lokela ho lokisoa ka letsoho ka nako ho thusa ho lekana hantle pakeng tsa khatello ea khatello le lesale la shoa;

4. Thepa e tala e tlameha ho hloekisoa pele le karohano ea makenete pele ho pelletizer ho fokotsa khatello ea tšepe ka har'a lesoba la die. Le ho hlahloba lesoba khafetsa ho bona hore na ho na le blockage. Hlakola kapa u phunye lesoba le thibileng la hlobo ka nako;

5. Deformation ea polasetiki ea lesoba la cone ea tataiso ea lesale e lokela ho lokisoa. Ha ho lokisoa, hoa lokela ho hlokomeloa hore karolo e tlaase ka ho fetisisa ea karolo e ka hare e sebetsang ea lesale e lokela ho ba 2mm e phahameng ho feta tlase ea groove ea overtravel, 'me ho ntse ho e-na le sebaka sa ho lokisa sekontiri sa khatello ea khatello ka mor'a ho lokisoa Ho seng joalo, selikalikoe se lokela ho tlosoa;

6. Khetla ea khatello ea khatello e entsoe ka lisebelisoa tsa alloy tse sa sebetseng ka ho sebetsa ha khauta le ho phekola mocheso. Leino holim'a sebopeho sa khetla ea rolara ea khatello e na le tšusumetso e itseng ts'ebetsong ea granulation.

Ka tloaelo ho sebelisoa profil ea meno ea li-roller: profil ea leino ka mofuta, profil ea leino eseng ka mofuta, mofuta oa lesoba.

1. Pass le meno groove rollers haholo-holo sebelisoa bakeng sa pelletizing liphoofolo tse ruiloeng le likhoho thepa. Molemo oa li-rollers ke hore lesale la ring le apara ka tsela e tšoanang, empa ts'ebetso ea coil e fokola.

2.The tooth groove shape pressure roller e na le ts'ebetso e ntle ea lisebelisoa tsa coil 'me e atisa ho sebelisoa lifekthering tsa phepelo, empa ho roala ha lesale ha ho tšoane. The leino groove sebopeho khatello ea rolara le ho tiisoa bohale bohale haholo-holo a loketse bakeng sa pelletizing ea lintho tse phelang metsing. Thellela ka mahlakoreng a mabeli.

HELICAL ROLLER SHEBA

Khetla ea rolara ke e 'ngoe ea likarolo tse ka sehloohong tse sebetsang tsa leloala la pellet. E sebelisoa ho sebetsana le li-pellets tse fapaneng tsa biofuel, lijo tsa liphoofolo le li-pellets tse ling. Ho sebelisa tšepe ea alloy e phahameng e sa sebetseng (40Cr, 20Crmnti, Gcr15), kalafo ea mocheso oa carburizing, boima ba junifomo. Bophelo ba ts'ebeletso bo bolelele, 'me ho na le mefuta e fapaneng ea meaho e kang leino le bōpehileng joaloka leino, le thibiloe ka sebōpeho sa leino, le sebopeho sa lesoba. Karolo e hatellang e entsoe ka shaft e ka hare ea eccentric le likarolo tse ling tse nang le litekanyo tse nepahetseng, tse loketseng ho lokisa sebaka se pakeng tsa rolara e hatellang le selikalikoe se shoang ho latela litlhoko tsa tlhahiso ea mosebelisi, 'me ho bonolo ho mena le ho kenya, mme ho bonolo ho nka sebaka sa khetla ea rolara e hatellang.

Mehato ya tlhokomelo:

1. Khetha ka nepo tekanyo ea compression ea lesoba le loketseng;

2. Lokisa ka nepo lekhalo la ho sebetsa pakeng tsa lesale la ho shoa le mochine oa khatello ho ba pakeng tsa 0.1 le 0.3mm (motlakase oa khatello o khannoa ke lesale le shoa ka mor'a hore granulator e ncha e buletsoe "e kang ho potoloha empa e sa potoloha" boemo) ;

3. Mochini o mocha oa lesale o lokela ho sebelisoa ka mochine o mocha oa khatello, 'me mochine oa khatello le lesale le lokela ho lokoloha pele ebe o tiisa. Ha likhutlo tse bohale li hlaha ka mahlakoreng a mabeli a khatello ea khatello, flange ea mochine oa khatello e lokela ho lokisoa ka letsoho ka nako ho thusa ho lekana hantle pakeng tsa khatello ea khatello le lesale la shoa;

4. Thepa e tala e tlameha ho hloekisoa pele le karohano ea makenete pele ho pelletizer ho fokotsa khatello ea tšepe ka har'a lesoba la die. Le ho hlahloba lesoba khafetsa ho bona hore na ho na le blockage. Hlakola kapa u phunye lesoba le thibileng la hlobo ka nako;

5. Deformation ea polasetiki ea lesoba la cone ea tataiso ea lesale e lokela ho lokisoa. Ha ho lokisoa, hoa lokela ho hlokomeloa hore karolo e tlaase ka ho fetisisa ea karolo e ka hare e sebetsang ea lesale e lokela ho ba 2mm e phahameng ho feta tlase ea groove ea overtravel, 'me ho ntse ho e-na le sebaka sa ho lokisa sekontiri sa khatello ea khatello ka mor'a ho lokisoa Ho seng joalo, selikalikoe se lokela ho tlosoa;

6. Khetla ea khatello ea khatello e entsoe ka lisebelisoa tsa alloy tse sa sebetseng ka ho sebetsa ha khauta le ho phekola mocheso. Leino holim'a sebopeho sa khetla ea rolara ea khatello e na le tšusumetso e itseng ts'ebetsong ea granulation.

Ka tloaelo ho sebelisoa profil ea meno ea li-roller: profil ea leino ka mofuta, profil ea leino eseng ka mofuta, mofuta oa lesoba.

1. Pass le meno groove rollers haholo-holo sebelisoa bakeng sa pelletizing liphoofolo tse ruiloeng le likhoho thepa. Molemo oa li-rollers ke hore lesale la ring le apara ka tsela e tšoanang, empa ts'ebetso ea coil e fokola.

2.The tooth groove shape pressure roller e na le ts'ebetso e ntle ea lisebelisoa tsa coil 'me e atisa ho sebelisoa lifekthering tsa phepelo, empa ho roala ha lesale ha ho tšoane. The leino groove sebopeho khatello ea rolara le ho tiisoa bohale bohale haholo-holo a loketse bakeng sa pelletizing ea lintho tse phelang metsing. Thellela ka mahlakoreng a mabeli.