Moetsi oa PTN Series Ring Die bakeng sa likarolo tsa lisebelisoa tsa leloala la Pellet

- SHH.ZHENGYI

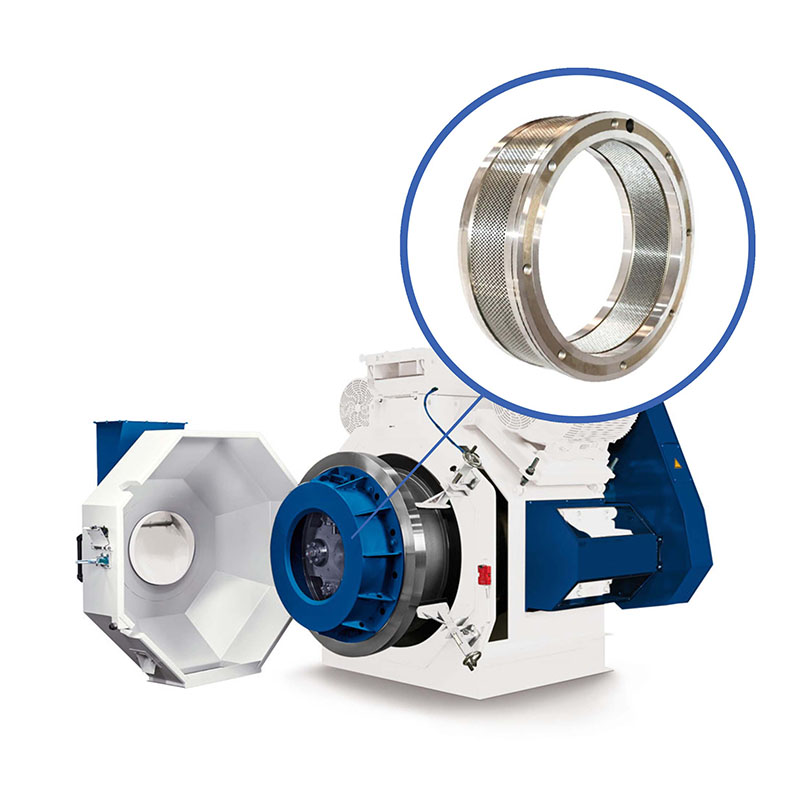

● PTN series ring die

PTN pellet mill series ring die e entsoe ka tšepe ea boleng bo holimo ea alloy kapa tšepe e sa jeleng ea chromium e phahameng (Sejeremane standard X46cr13). E sebetsoa ka ho forging, ho itšeha, ho phunya, kalafo ea mocheso le lits'ebetso tse ling. Ka tsamaiso e tiileng ea tlhahiso le tsamaiso ea boleng, ho thatafala, ho tšoana ha lesoba le lefu la ho qetela la lesale la tlhahiso la lihlahisoa li fihlile boleng bo phahameng haholo.

Paramethara

| S/N | Mohlala | BoholoOD * ID * bophara ka kakaretso * bophara ba pad -mm | Boholo ba lesobamm |

| 1 | PTN450 | 560*450*180*106 | 1-12 |

| 2 | PTN580 | 680*580*216*140 | 1-12 |

| 3 | PTN650 | 791*650*245*175 | 1-12 |

Tlhahlobo ea Maemo a sa Tloaeleheng le Lintlafatso Tse Reteletsoeng

Tlhaloso ea Mabaka bakeng sa Broken (hangata e etsahetse ka

ts'ebetso e tsoelang pele ea likhoebo tse nyane)

1. Shoa e robehileng ka ho khanna lebili matching holim'a

2. Shoa e robehileng ka ho roala le ho senyeha ha selikalikoe sa lefu.

3. Shoa robehile ka waring ea ho khanna senotlolo.

4. Indentation e hatisitsoeng holim'a lefu bakeng sa phello e fokolang ea sesebelisoa sa de-ironing, ebe e etsa hore lefu le phunye.

5. Lekhalo le lenyenyane pakeng tsa pola le compression rolara.

6. E-shoa e robehileng ka tekanyo e nyane ea compression, phepelo ea tlhapi e nyane ea bophara e shoa ntle le moea oa ho imolla khatello.

| Che. | Ponahalo | Mabaka | Litharollo |

| 1 | Particle e kobeha, e nang le mapetsong |

| |

| 2 | E nang le mapheo a mosehla |

| |

| 3 | Mapetso a emeng |

| |

| 4 | Maphatso a mahlaseli | Ho na le likaroloana tse kholo (halofo ea oorn kapa poone e setseng) | Laola fineness ea lihlahisoa tse tala, eketsa ho sila evenness. |

| 5 | Ho se leka-lekane ha bokahodimo |

| |

| 6. | Hlatsoa joalo ka pellet | Mouoane o mongata haholo le khatello e kholo haholo, pellet ea peperana ha e tloheloa lefu. | 1. Fokotsa khatello ea mouoane, sebelisa mouoane o tlaase (15 - 20psi) bakeng sa boemo. 2. Sheba boemo ba valve e fokotsang. |