Particle kuomarara ndeimwe yemhando zviratidzo izvo kambani yese yekudyisa inobhadhara zvakanyanya. Muchikafu chezvipfuyo nehuku, kuoma kwakanyanya kunokonzeresa kusanzwa zvakanaka, kuderedza kudya, uye kutokonzera maronda emukanwa munguruve dzinoyamwisa. Zvisinei, kana kuoma kwakaderera, hupfu hwehupfu huchaderera. Kuwedzera, kunyanya kuomarara kwakaderera kwezvinhu zvepellet zvinokonzeresa zvisingafadzi zvinhu zvakaita sechikamu chekudya. Naizvozvo, mabhizinesi anofanirwa kuve nechokwadi chekuti kuomarara kwekudya kunosangana nemhando yepamusoro. Pamusoro pekugadzirisa fomula yekudyisa, ivo vanotarisawo pamatanho akasiyana-siyana ekugadzira uye kugadzirisa maitiro, ayo anozovewo nemhedzisiro yakakosha pakuoma kwepellet feed.

1) Chinhu chinotora chikamu mukuoma kwezvimedu mugayo rekugaya ndiko kukuya chidimbu chehukuru hwezvigadzirwa. Kazhinji, kukwenenzvera ukuru hwezvimedu zvezvigadzirwa, zviri nyore kuti starch iite gelatinize panguva yekumisikidza, uye kusimba kwekubatana kwema pellets. Izvo zvishoma kuputsika nyore, kunowedzera kuoma. Naizvozvo, mukugadzirwa chaiko, saizi yekupwanya chidimbu inoda kugadziridzwa zvinoenderana nekugadzirwa kwemhuka dzakasiyana uye saizi yemhete kufa aperture.

2) Kuburikidza nekuputira kurapa kwezvinhu zvakabikwa, chepfu mumidziyo inogona kubviswa, mabhakitiriya anogona kuurayiwa, zvinhu zvinokuvadza zvinogona kubviswa, mapuroteni ari muzvigadzirwa zvinogona kubviswa, uye starch inogona kuzara gelatinized. Parizvino, zvinhu zvakazvitutumadza zvinonyanya kushandiswa mukugadzira chikafu chenguruve chinoyamwa chepamusoro-soro uye chikafu chakakosha chemvura. Nokuda kwezvigadzirwa zvemvura zvakakosha, mushure mokunge zvinhu zvakasvibiswa zvakasvibiswa, chiyero che starch gelatinization chinowedzera uye kuoma kwezvikamu zvakaumbwa zvinowedzerawo, izvo zvinobatsira kuvandudza kugadzikana kwezvikamu mumvura. Pakudya kwenguruve inoyamwa, zvimedu zvinodiwa kuti zvive crispy uye kwete zvakanyanya kuoma, izvo zvinobatsira pakudyisa nguruve inoyamwa. Zvisinei, nekuda kwehupamhi hwestarch gelatinization muhutu hunoyamwa nguruve pellets, kuoma kwemafuro ekudya kwakakurawo.

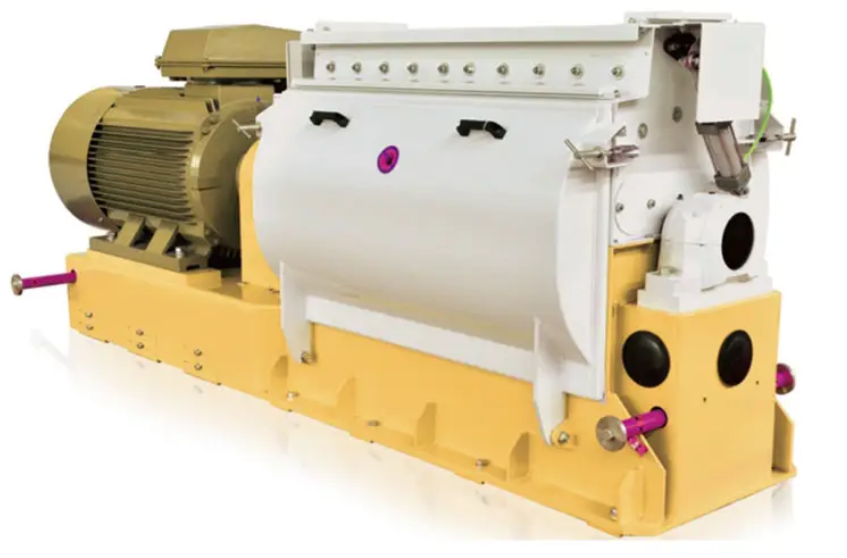

3) Iko kusanganiswa kwezvinhu zvakasvibirira kunogona kuvandudza kuwirirana kweakasiyana siyana saizi zvikamu, izvo zvinobatsira kuchengetedza kuomarara kwechikamu kunoenderana uye kugadzirisa mhando yechigadzirwa. Mukugadzirwa kwekudya kwepellet yakaoma, kuwedzera 1% kusvika 2% mwando mumusanganisi kuchabatsira kuvandudza kugadzikana uye kuoma kwepellet feed. Zvisinei, zvakakoshawo kufunga nezvemigumisiro yakaipa yekuwedzera kwehunyoro pakuoma uye kutonhora kwepellets. Izvo zvakare hazvibatsiri kuchengetedza chigadzirwa. Mukugadzirwa kwemvura yepellet feed, inosvika 20% kusvika 30% mwando inogona kuwedzerwa kuhupfu. Zviri nyore kuwedzera nezve 10% mwando panguva yekusanganiswa pane panguva yekugadzirisa. Ma pellets akaumbwa kubva kune yakakwirira-unyoro zvinhu ane yakaderera kuoma, kupfava uye kunaka palatability. Mabhizinesi akakura ekupfuya anogona kushandisa ichi chet pellet feed. Wet pellets haawanzo kuve nyore kuchengeta uye anowanzo kudiwa kupihwa chikafu nekukurumidza mushure mekugadzirwa. Kuwedzera oiri panguva yekusanganisa maitiro inowanzoshandiswa mafuta ekuwedzera maitiro mumashopu ekugadzira chikafu. Kuwedzera 1% kusvika 2% yegirizi haina mhedzisiro yekudzikisa kuoma kwezvikamu, nepo kuwedzera 3% kusvika 4% yegirizi kunogona kuderedza zvakanyanya kuoma kwezvikamu.

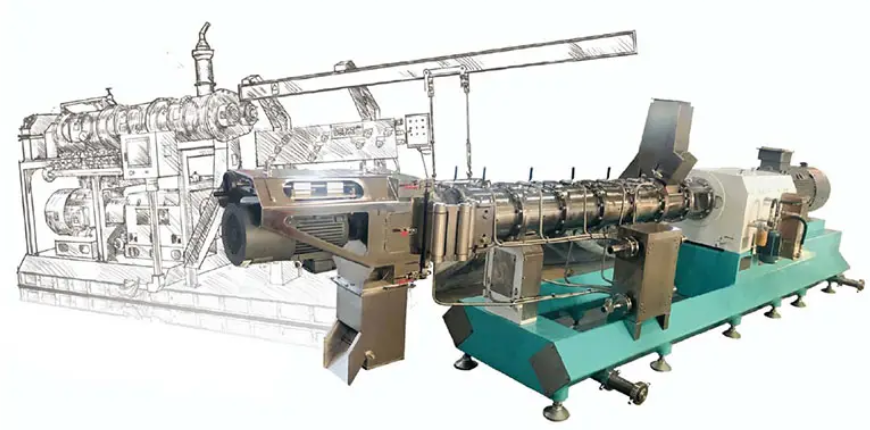

4) Steam conditioning inzira yakakosha mukugadziriswa kwepellet feed, uye mamiriro ekugadzirisa anokanganisa zvakananga chimiro chemukati uye kutaridzika kwemhando yepellets. Steam mhando uye nguva yekumisikidza zvinhu zviviri zvakakosha zvinokanganisa maitiro ekugadzirisa. Yepamusoro-soro yakaoma uye yakasvibiswa steam inogona kupa kupisa kwakawanda kuwedzera kutonhora kwezvinhu uye gelatinize starch. Iyo yakareba nguva yekumisikidza, inowedzera dhigirii ye starch gelatinization. Iyo yakakwirira kukosha, iyo denser chimiro chechidimbu mushure mekugadzira, zviri nani kugadzikana, uye kukura kuoma. Zvekudya hove, maviri-layer kana akawanda-layer jackets anowanzo shandiswa kugadzirisa kuwedzera tembiricha yekumisikidza uye kuwedzera nguva yekumisikidza. Zvinonyanya kubatsira pakuvandudza kugadzikana kwehove dzekudya kwehove mumvura, uye kuoma kwezvikamu kunowedzerawo maererano.

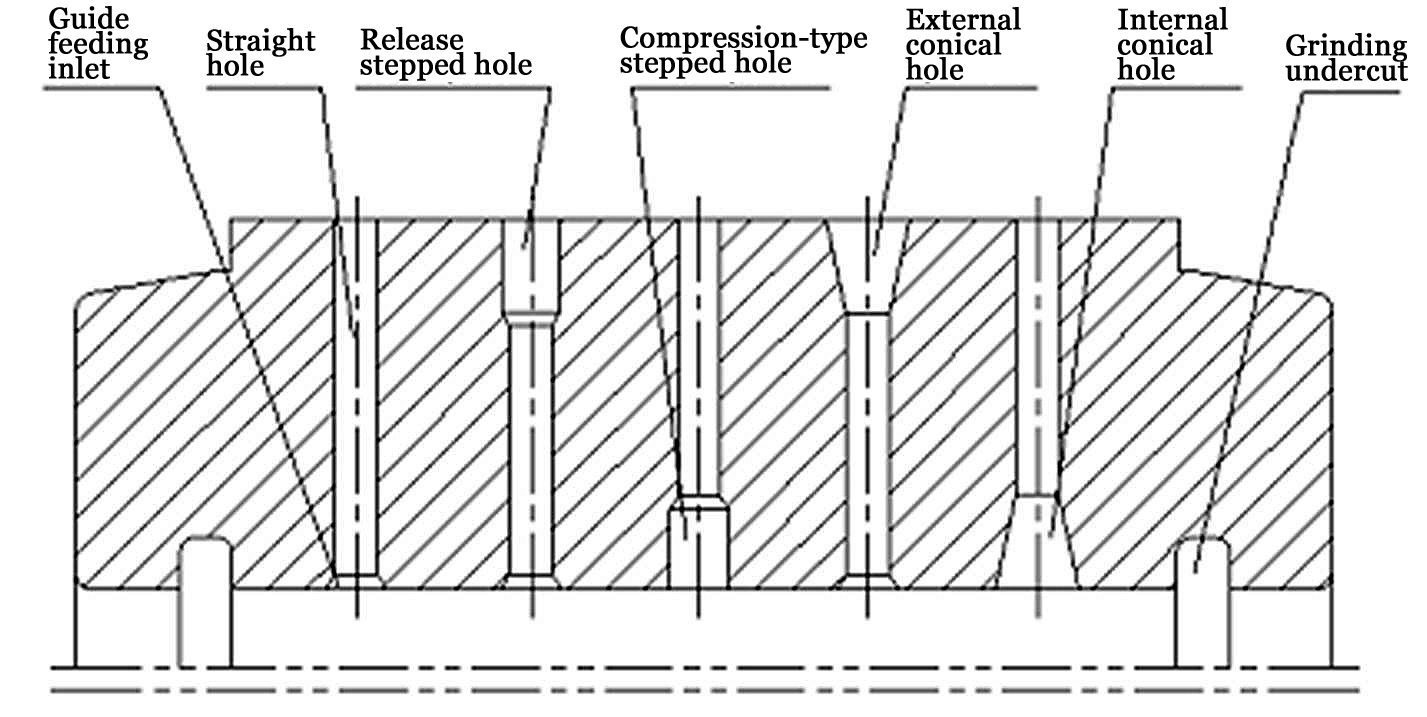

5) Munguva ye granulation process, tekinoroji paramita senge aperture uye compression ratio yemhete inofa ichakanganisawo kuoma kwezvikamu. Kuomarara kwezvimedu zvakaumbwa nemhete mold ine aperture yakafanana asi mareshiyo akasiyana ekumanikidza achawedzera zvakanyanya nekuwedzera kwereshiyo yekumanikidza. . Kusarudza rin'i inofa ine yakakodzera compression reshiyo inogona kuburitsa zvimedu zvine kuoma kwakakodzera. Panguva imwecheteyo, kureba kwezvimedu kunewo zvakakosha pakumanikidzika-kutakura simba rezvikamu. Kune zvidimbu zvedhayamita imwe chete, kana zvimedu zvisina kukanganisa, kureba kwechidimbu, kunowedzera kuoma kwakayerwa. Nokudaro, kugadzirisa nzvimbo yekucheka kuti uchengetedze hurefu hwakakodzera hwechidimbu hunogona kuchengetedza kuoma kwezvikamu zvakanyatsoenderana. Iyo particle dhayamita uye muchinjika-chikamu chimiro zvakare zvine imwe mhedzisiro pakuoma kwechidimbu. Mukuwedzera, zvinhu zvemhete inofa inewo imwe mhedzisiro pakuonekwa kwemhando uye kuoma kwepellets. Pane misiyano iri pachena pakati pekudya kwepellet inogadzirwa nesimbi yakajairwa mhete inofa uye simbi isina tsvina inofa.

Kuti uwedzere nguva yekuchengetedza yezvigadzirwa zvekudya uye kuve nechokwadi chemhando yechigadzirwa mukati meimwe nguva yenguva, kuomeswa kwakakodzera uye kutonhora kugadziridzwa kwezvimedu zvekudya kunodiwa.