Iyo inofa ndicho chikamu chepakati muchigayo chepellet. Uye ndiyo kiyi yekukugadzira mapepa ekudya. Zvinoenderana nehuwandu husina kukwana, mutengo wepellet mill kufa kurasikirwa account inodarika makumi maviri neshanu muzana yemari yekugadzirisa yemusangano wese wekugadzira. Kune yega yega chikamu chekuwedzera kwemubhadharo, kukwikwidza kwako kwemusika kunodonha ne0.25%. Saka iyo pellet mill yakatarwa yakakosha zvakanyanya.

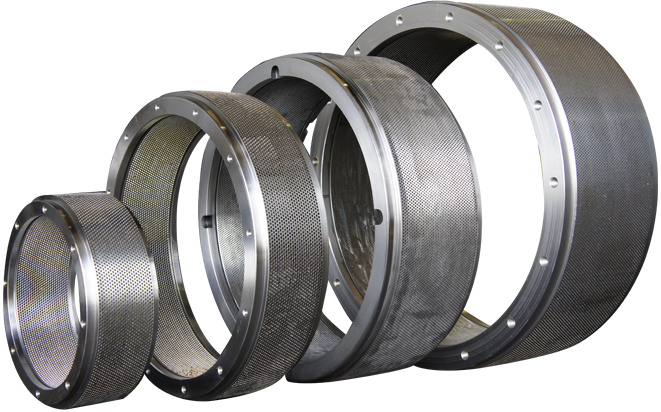

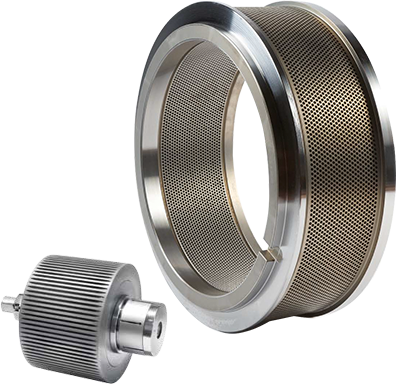

Shanghai Zhengyi (CPSHZY) inyanzvifeed pellet millmutengesi muchina. Isu tinopa ring die pellet mill, flat die pellet mill uye iyopellet mill zvikamu, senge flat die, ring die, pellet mill roller, uye zvimwe zvikamu zvemuchina wepellet.

1.Pellet mill die material

Iyo pellet mill inofa inowanzo gadzirwa nekabhoni simbi, alloy dhizaini simbi kana simbi isina tsvina kuburikidza nekugadzira, machining, maburi ekuchera, uye maitiro ekurapa kupisa. Mushandisi anogona kusarudza zvinoenderana nekuora kweiyo particle mbishi zvinhu. Izvo zvinhu zvepellet mill kufa zvinofanirwa kugadzirwa nealloy chimiro simbi kana Stainless simbi mhete mold.

Carbon structural simbi, senge 45 simbi, kupisa kwayo kuomarara kuoma kunowanzo 45-50 HRC, ndeye yakaderera-giredhi mhete inofa zvinhu, yayo kusapfeka uye kusagadzikana nekuora kwakashata, iko zvino kwabviswa.

Alloy structural simbi, yakadai se40Cr, 35CrMo, nezvimwewo, ine kupisa kwekupisa kuomarara pamusoro pe50HRC uye yakanaka yakasanganiswa michina zvinhu. Iyo inofa yakagadzirwa nechinhu ichi ine simba rakakwirira uye kupfeka kusagadzikana, asi chinokanganisa ndechokuti kurwisana nehutu hakuna kunaka, kunyanya kudya kwehove.

Mutengo wemhete inofa, iyo inogadzirwa nezvinhu, marigold pellets, huni huni, mashanga emashanga, nezvimwewo, yakakwirira kudarika simbi isina tsvina. Ose ari maviri 20CrMnTi uye 20MnCr5 masimbi akadzika-carburizing alloy, ese ari maviri akafanana, kunze kwekuti yekutanga iChinese simbi uye yekupedzisira yeGerman simbi. Sezvo Ti, chinhu chemakemikari, chisingawanzo kuwanikwa kunze kwenyika, 20CrMnTi kana 20CrMn kubva kuChina inoshandiswa pachinzvimbo che20MnCr5 kubva kuGermany, saka haiwire mukati mechikamu chesimbi yealloy. Nekudaro, iyo yakaomeswa simbi yesimbi iyi inoganhurwa neiyo carburizing process kusvika pahupamhi hwehupamhi hwe 1.2 mm, inovawo mukana wemutengo wakaderera wesimbi iyi.

Stainless simbi zvinhu zvinosanganisira German Stainless simbi X46Cr13, China Stainless simbi 4Cr13, etc. Zvinhu izvi zviri nani kuoma uye kuomarara, yakakwirira kupisa kupisa kuomarara kupfuura carburized simbi, akaomeswa layers kupfuura carburized simbi, uye zvakanaka kupfeka uye ngura kuramba, zvichiita upenyu hurefu uye. mitengo yakakwira kupfuura simbi yakabikwa. Nekuda kwehupenyu hurefu hwesimbi isina tsvina inofa simbi, iyo yekutsiva frequency yakaderera uye saka mutengo patani wakaderera.

Kazhinji, iyo inofa yemhete die pellet mill ndiyo alloy structural simbi uye Stainless simbi zvinhu.

2.Compression ratio yepellet mill inofa

i=d/L

T=L+M

M ndiko kudzika kwegomba rakaderedzwa

The Compression ratio (i) ireshiyo yedhiyabhorosi dhayamita (d) uye hurefu hunoshanda (L) hwefa.

Zvinoenderana nemasikirwo ezvakagadzirwa, reshiyo ndeye 8-15, Mushandisi anosarudza iyo compression ratio yefa, uye anogadzirisa chaiyo compression reshiyo, sekusarudza yakaderera zvishoma yekumanikidza reshiyo, inobatsira kuwedzera kubuda, kuderedza kushandiswa kwesimba, kuderedza kupfekedzwa kwechindori chemhete, asiwo kuderedza kunaka kwezvikamu, zvakadai semapellets asina kusimba zvakakwana, kutaridzika kwakasununguka uye kureba kwakasiyana, uye chiyero cheupfu chakakwirira.

3.Kuvhura mwero wemhete kufa

Chiyero chekuvhura chepellet mill die ireshiyo yenzvimbo yese yegomba rekufa kusvika kune inoshanda yakazara nzvimbo yefa. Kazhinji, iyo yakakwirira yero yekuvhura yefa, inowedzera goho rechikamu. Pasi pemamiriro ekuona simba rekufa, chiyero chekuvhura chemhete chinofa chinogona kuvandudzwa kusvika pazvinobvira.

Kune zvimwe zvinhu zvakasvibirira, pasi pemamiriro ehutano hwekumanikidza reshiyo, iyo pellet mill kufa madziro yakanyanya kutetepa, kuitira kuti simba rekufa harina kukwana, uye chiitiko chekuputika kufa kuchaonekwa mukugadzirwa. Panguva ino, kuwanda kwechindori kufa kunofanira kuwedzerwa pasi pechikonzero chekuona hurefu hunobudirira hwegomba rekufa.

4.Kufananidza pakati pellet mill die uye roller

Ndiyo yakanyanya kukosha tekinoroji yekuvandudza kushanda kwegranulation uye kurebesa hupenyu hwekufa. Inofanira kusanganisira 4 maitiro:

- Mhete nyowani inofa ine nyowani yekumanikidza roller, dzivirira kushandisa zvakanyanya kumanikidza roller.

- Zvinoenderana nehunhu hwezvishandiso, mhando yemuchina hunhu hwekusarudzwa kwemhando dzakasiyana dzekumanikidza roller, kuitira kuti uwane yakanakisa extrusion kunyatsoshanda pakati pekufa uye roll.

- Chinokosha chegap fit kugadzikana uye nheyo ndeyokuti: pasina kukanganisa kukwanisa, edza kuzorora.

- Kudzora kukurumidza kudyisa, gadzirisa iyo yakareba uye ipfupi chinzvimbo chekudyisa scraper kudzora nzvimbo yekudyisa, zvinhu layer kugovera.

5.Pellet mill die process process

Makomba emhete ari kudiwa zvakanyanya maererano nekugadzirisa uye kugadzira michina, uye yesimbi isina tsvina, yakakosha pfuti yekurovera uye vacuum yekupisa yemidziyo yekurapa inodiwa kugadzira yemhando yepamusoro mhete inofa. Iyo yakanakisa tembiricha yekumisa vacuum yekudzima maitiro inogona zvakanyanya kuvandudza kuoma, kuoma, abrasion kuramba, kuneta simba uye kuoma kwesimbi. Nekudaro, kugona kuvimbisa yakaenzana kuomarara layer kune yega yega gomba rinoda hunyanzvi hwekugadzirisa uye ruzivo rurefu.

6.Iyo dies surface roughness yemukati memadziro efa hole

Kushata kwepamusoro zvakare chiratidzo chakakosha chemhando yemhete. Muzhinji, kukosha kudiki kwemukati wemadziro pamusoro roughness kuchavandudza kunaka kwekukodzera, kuderedza kupera uye kuwedzera hupenyu hwemhete kufa, asi mutengo wekugadzirisa mhete kufa kuchawedzera.

Mhete yegomba roughness inokanganisawo compression ratio uye kuumbwa kwezvikamu, pamwe nekubudirira kwekugadzira. Panguva imwecheteyo mhete inofa compression reshiyo, iyo yakaderera kukosha kwehukasha, inodzikira iyo extrusion kuramba yehuni machipisi kana chikafu, iyo inotsvedzerera kubuda, kukwirisa kunaka kwemapellets anogadzirwa uye kukwirisa kugadzirwa kwakanaka. Yakanaka mhete yekufa kwegomba kugadzirisa inogona kusvika 0.8-1.6 microns, mhete kufa roughness ingangoita 0.8 microns, muchina chaiwo pane zvinoraswa zvinhu, hapana kugaya.