OEM/ODM Supplier Leaf Pellet Mill - Best manufacturer of VAN AARSEN Ring Die for Pellet mill spare parts – Zhengyi

- SHH.ZHENGYI

OEM/ODM Supplier Leaf Pellet Mill - Best manufacturer of VAN AARSEN Ring Die for Pellet mill spare parts – Zhengyi Detail:

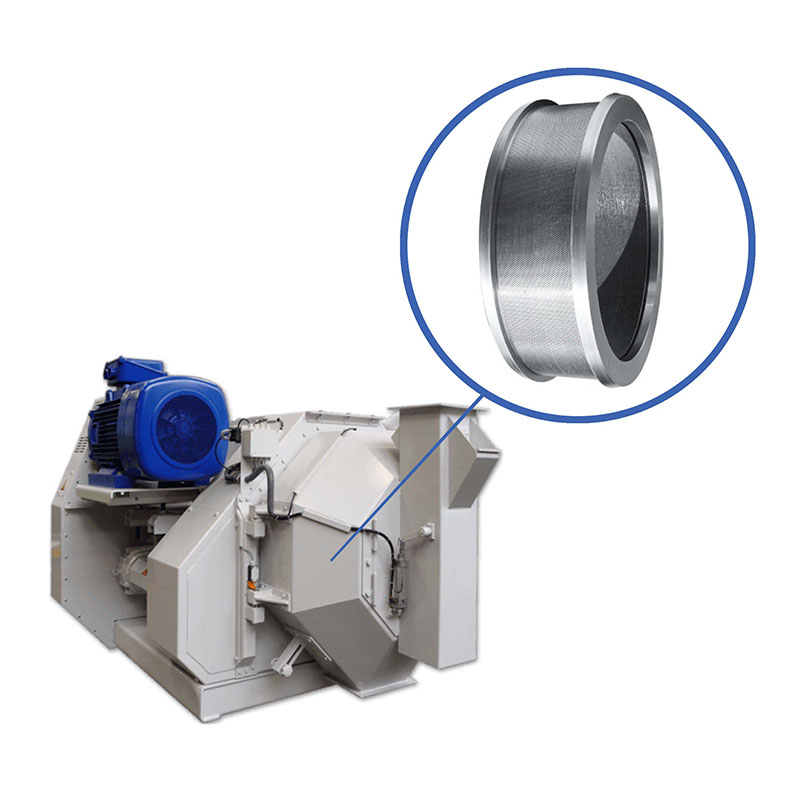

● VAN AARSEN series ring die

Van Aarsen pellet mill series ring die is made of high-quality alloy steel or high-chromium stainless steel (German standard X46cr13). It is processed by forging, cutting, drilling, heat treatment and other processes. Through strict production management and quality system, the hardness, die hole uniformity and die hole finish of the production ring die have reached very high quality.

Parameter

| S/N | Model | Size OD*ID*overall width*pad width -mm | Hole size mm |

| 1 | Van AarsenC500-165 | 652*500*265*165 | 1-12 |

| 2 | Van AarsenC600-200 | 750*600*300*200 | 1-12 |

| 3 | Van AarsenC750-215 | 900*750*315*215 | 1-12 |

| 4 | Van AarsenC900-225 | 1050*900*325*225 | 1-12 |

| 5 | Van AarsenC900-275 | 1050*900*375*275 | 1-12 |

| 6 | Van AarsenC900-325 | 1050*900*425*325 | 1-12 |

| 7 | Van AarsenR900 | 1040*900*325*215 | 1-12 |

Strictly controlled quality management system

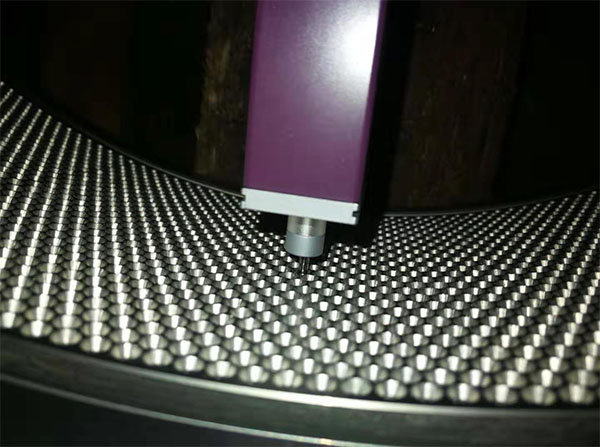

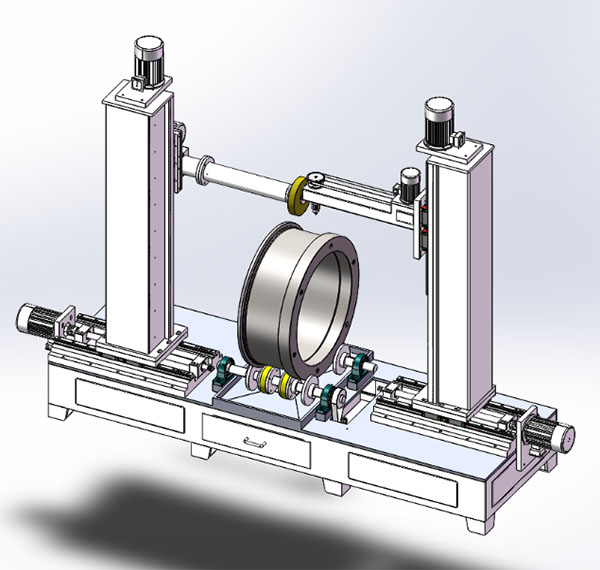

Ring die repair Machine

Tech Data:

Operating system: fully automatic operation Dimensions (mm) : 2300*1400*2070

Workpiece size: 420mm≤ 1100mm inner diameter

Processing aperture range: 1.6mm≤ 8.0mm aperture

Hole processing efficiency: depending on the aperture and processing depth, 3.0mm, processing depth of 10mm,1 hole /S

Internal grinding efficiency: depending on the flatness of the ring die face, the maximum horizontal feed is 32mm/s, and the maximum feed amount of grinding is 0.02mm/ tool

Total Power: 5KW

Product detail pictures:

Related Product Guide:

Our organization has been focusing on brand strategy. Customers' gratification is our greatest advertising. We also source OEM provider for OEM/ODM Supplier Leaf Pellet Mill - Best manufacturer of VAN AARSEN Ring Die for Pellet mill spare parts – Zhengyi , The product will supply to all over the world, such as: Egypt, Morocco, France, Now, we professionally supplies customers with our main products And our business is not only the buy and sell, but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!