OEM Manufacturer Pellet Hammer Mill - Tear Circle Type Hammer MillMachine for Feed industry – Zhengyi

- SHH.ZHENGYI

OEM Manufacturer Pellet Hammer Mill - Tear Circle Type Hammer MillMachine for Feed industry – Zhengyi Detail:

Hammer mill for the grinding of pellet and powder raw material in feed., food, chemical industry. Brewing industry and so on.

The grinding chamber is the water-drop type and U-shaped second grinding mechanism is on the bottom of the grinding chamber which can effectively eliminate circumfluence and increase 25% throughput.

Rotor passes the dynamic balance testing and adopts imported SKF bearing with the advantages of low noise, long operating life, and little maintenance.

Feed pellet equipment: water drop crusher (pig feed crusher).

Product Description

As one of the commonly feed equipment, the water drop crusher is mainly used to crush raw materials into small particles or powder suitable for particle manufacturing. It has the following characteristics:

1. The crushing chamber is of true water-drop shape, and the air inlet mode can effectively avoid air circulation phenomenon in the crushing process; The U-shaped secondary striking groove is set high at the bottom of the crushing chamber to greatly improve the output. The fully open operation door and elastic screen pressing mechanism can greatly facilitate the maintenance and replacement of screen pieces.

2. Imported SKF bearings are used to ensure service life; The nylon-rod type coupling device is directly driven, which could compensate large displacement and effectively avoid bearing heating.

3. The rotor has been verified by dynamic balance to Ensure more balanced operation, lower noise, and better performance.

4. Through adjustment, coarse crushing, fine crushing, and micro crushing can be realized, so that one machine can be used for multiple purposes.

5. The feed inlet is on the top of the crusher and can be matched with various forms of feeding mechanisms.

6. It is mainly used for crushing various granular raw materials, such as corn, sorghum, wheat, beans, etc.

Parameter

| MODEL | POWER(KW) | CAPACITY(t/h) | FEEDER MODEL |

| SFSP300 | 55/75 | 8-12 | SWLY300 |

| SFSP400 | 75/90/110 | 12-20 | SWLY400 |

| SFSP600 | 132/160 | 20-30 | SWLY600 |

| SFSP800 | 200/220 | 30-42 | SWLY800 |

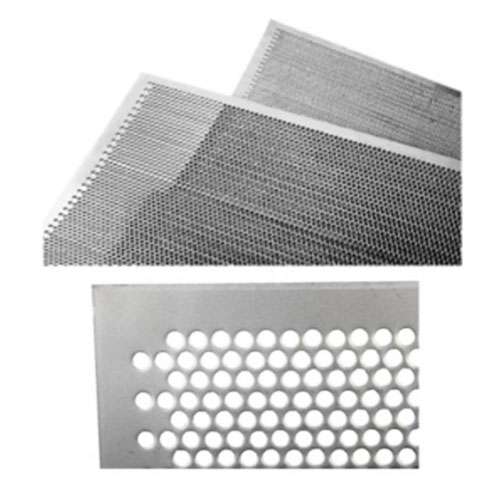

The spare parts for water drop hammer mills include:

1. ROTOR HAMMER TABLET

2. BEARING WITH THE BASE

3. SIEVE PLATE

4. GRINDING ROOM WITH MULTI-CHAMBER

Product detail pictures:

Related Product Guide:

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for OEM Manufacturer Pellet Hammer Mill - Tear Circle Type Hammer MillMachine for Feed industry – Zhengyi , The product will supply to all over the world, such as: Iran, US, Riyadh, The company has numbers of foreign trade platforms, which are Alibaba,Globalsources,Global Market,Made-in-china. XinGuangYang HID brand products sell very well in Europe, America, Middle East and other regions more than 30 countries.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.