OEM Customized Single Shaft Mixer - Feed industry BUHLER Series Ring Die for Pellet mill spare parts – Zhengyi

- SHH.ZHENGYI

OEM Customized Single Shaft Mixer - Feed industry BUHLER Series Ring Die for Pellet mill spare parts – Zhengyi Detail:

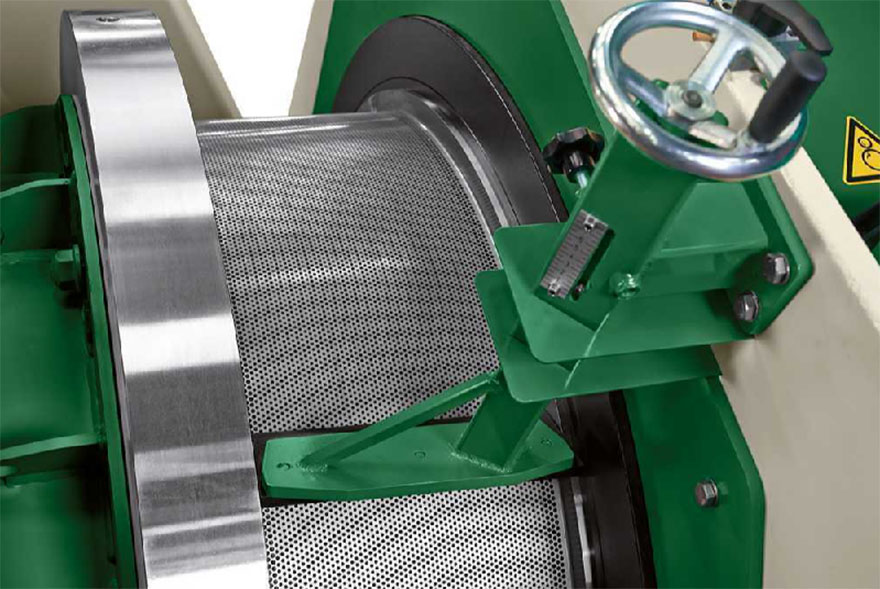

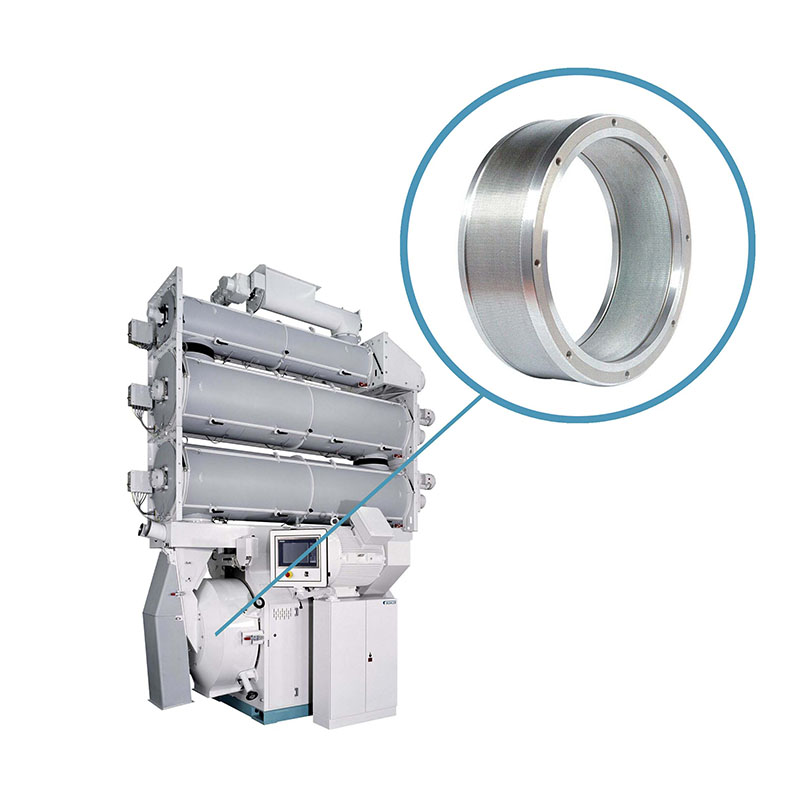

Zhengyi Ring Die of Spare Parts of Pellet mill

Using Euro Standard X46Cr13 and strictly production process control, the products with high precision have reached the first-class level of the industry in terms of assembly size and hole wall smoothness. The mature vacuum heat treatment process ensures the service life of the ring die products and brings customers a good experience in using the ring die.

We obtained a certificate of production for Ring Die and Roller shell in 2015

Advantage of Our Pellet Mill Ring Die

1. Select high-quality raw materials, secondary steelmaking, degassing billet.

2. Ring die material: X46Cr13 / 4Cr13 (stainless steel), 42Crmo / 20CrMnTi (alloy steel) or other custom materials.

3. Imported gun drill and multi-station drill, one-time forming die hole, high-quality finish, production of feed, beautiful appearance and high output.

4. Select the combination of vacuum furnace and continuous quenching furnace to ensure long service life.

5. According to the principle and requirements of the customer to design compression ratio and strength.

6. Microscopic examination to ensure product quality.

X46Cr13 / 4Cr13 stainless steel ring die processing technology:

● BUHLER series ring die

BUHLER pellet mill series ring die is made of high-quality alloy steel or high-chromium stainless steel (German standard X46cr13). It is processed by forging, cutting, drilling, heat treatment and other processes. Through strict production management and quality system, the hardness, die hole uniformity and die hole finish of the production ring die have reached very high quality.

Parameter

| S/N | Model | Size OD*ID*overall width*pad width -mm | Hole size mm |

| 1 | Buhler350 | 500*350*180*100 | 1-12 |

| 2 | Buhler400 | 558*400*200*120 | 1-12 |

| 3 | Buhler420*180 | 489*420*152*108 | 1-12 |

| 4 | Buhler420*138 | 489*420*182*138 | 1-12 |

| 5 | Buhler420*140 | 580*420*217*140 | 1-12 |

| 6 | Buhler520*138 | 610*520*182*138 | 1-12 |

| 7 | Buhler520*178 | 617*520*212*178 | 1-12 |

| 8 | Buhler660*178 | 799*660*236*178 | 1-12 |

| 9 | Buhler660*28 | 790*660*286*228 | 1-12 |

| 10 | Buhler660*265 | 790*660*324*265 | 1-12 |

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of regard the market, regard the custom, regard the science as well as theory of quality the basic, have faith in the initial and administration the advanced for OEM Customized Single Shaft Mixer - Feed industry BUHLER Series Ring Die for Pellet mill spare parts – Zhengyi , The product will supply to all over the world, such as: Paraguay, Mozambique, Sydney, Our company covers an area of 20, 000 square meters. We have more than 200 workers, professional technical team, 15 years' experience, exquisite workmanship, stable and reliable quality, competitive price and sufficient production capacity, this is how we make our customers stronger. If you have any inquiry, please do not hesitate to contact us.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.