Imfa ndiye gawo lalikulu la mphero ya pellet. Ndipo ndiye chinsinsikupanga mapepala a chakudya. Malinga ndi ziwerengero zosakwanira, mtengo wotayika wa mphero umaposa 25% ya mtengo wokonza msonkhano wonse wopanga. Pakuwonjezeka kwa chiwongola dzanja chilichonse, mpikisano wanu wamsika umatsika ndi 0.25%. Chifukwa chake, mawonekedwe a pellet ndi ofunika kwambiri.

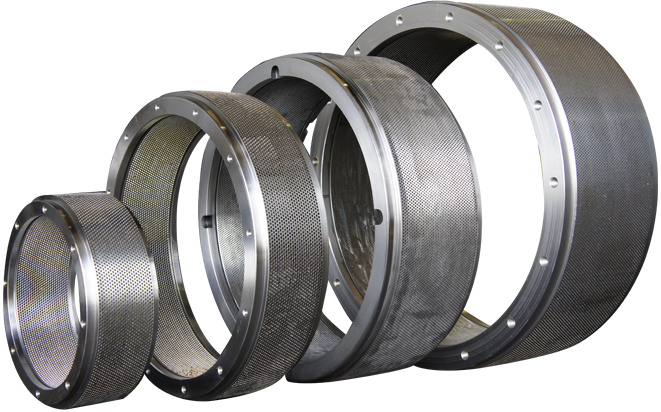

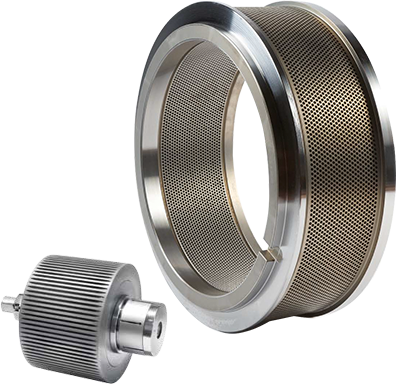

Shanghai Zhengyi (CPSHZY) ndi katswirichakudya pellet mpherowogulitsa ku china. Timapereka mphero ya ring die pellet, flat die pellet mphero ndimagawo a mphero, monga lathyathyathya kufa, mphete kufa, pellet mphero wodzigudubuza, ndi mbali zina za makina pellet.

1.Pellet mphero kufa zinthu

Chigayo cha mphero nthawi zambiri chimapangidwa ndi chitsulo cha kaboni, chitsulo chopangidwa ndi aloyi kapena chitsulo chosapanga dzimbiri popanga, kukonza, kubowola mabowo, ndi njira zochizira kutentha. Wosuta akhoza kusankha malinga ndi dzimbiri wa tinthu yaiwisi. Zomwe zimapangidwa ndi pellet mphero ziyenera kupangidwa ndi aloyi kapangidwe kachitsulo kapena chitsulo chosapanga dzimbiri nkhungu.

Chitsulo chopangidwa ndi mpweya, monga chitsulo 45, kuuma kwake kwa kutentha kumakhala 45-50 HRC, ndi mphete yotsika kwambiri, kukana kwake komanso kukana dzimbiri ndizosauka, zomwe zathetsedwa tsopano.

Aloyi structural zitsulo, monga 40Cr, 35CrMo, etc., ndi kutentha mankhwala kuuma pamwamba 50HRC ndi zabwino Integrated makina katundu. Imfa yopangidwa ndi nkhaniyi imakhala ndi mphamvu zambiri komanso kukana kuvala, koma choyipa ndichakuti kukana kwa dzimbiri sikwabwino, makamaka pakudyetsa nsomba.

Mtengo wa mphete umafa, womwe umapangidwa ndi zinthu, mapepala a marigold, tchipisi tamatabwa, mapepala a udzu, etc., ndi apamwamba kwambiri kuposa zitsulo zosapanga dzimbiri. Onse 20CrMnTi ndi 20MnCr5 ndi zitsulo zotsika kwambiri za carburizing, zomwe zili zofanana, kupatula kuti zakale ndizitsulo zaku China komanso zitsulo zomaliza za Germany. Popeza Ti, chinthu chamankhwala, sichipezeka kunja kwenikweni, 20CrMnTi kapena 20CrMn yochokera ku China imagwiritsidwa ntchito m'malo mwa 20MnCr5 yaku Germany, chifukwa chake sichigwera mkati mwa chitsulo chopangidwa ndi alloy. Komabe, chitsulo chowumitsidwa chachitsulochi chimakhala chochepa ndi ndondomeko ya carburizing mpaka kuya kwa 1.2 mm, yomwe ilinso mwayi wamtengo wotsika wachitsulo ichi.

Zida zachitsulo zosapanga dzimbiri zikuphatikizapo zitsulo zosapanga dzimbiri zaku Germany X46Cr13, China 4Cr13 zitsulo zosapanga dzimbiri, etc. Zidazi zimakhala ndi kuuma bwino komanso kulimba, kuuma kwa kutentha kwapamwamba kuposa zitsulo zopangidwa ndi carburized, zigawo zolimba kuposa zitsulo zopangidwa ndi carburized, ndi kuvala bwino ndi kukana dzimbiri, zomwe zimapangitsa moyo wautali komanso mitengo mwachibadwa kuposa zitsulo carburized. Chifukwa cha moyo wautali wa zitsulo zosapanga dzimbiri zofewa, mafupipafupi olowa m'malo ndi otsika choncho mtengo wa tani ndi wotsika.

Nthawi zambiri, zinthu zakufa za mphete ya die pellet mphero ndi alloy structural chitsulo ndi zitsulo zosapanga dzimbiri.

2.Kuponderezana kwa pellet mphero kufa

ndi =d/L

T=L+M

M ndiye kuya kwa dzenje lochepetsedwa

The Compression ratio (i) ndi chiŵerengero cha madiresi awiri (d) ndi kutalika kwake (L) kwa kufa.

Malinga ndi chilengedwe cha zopangira, chiŵerengero ndi 8-15, Wogwiritsa amasankha psinjika chiŵerengero cha kufa, ndi kusintha yeniyeni psinjika chiŵerengero, monga kusankha otsika psinjika chiŵerengero, amene n'kopindulitsa kuonjezera linanena bungwe, kuchepetsa kugwiritsira ntchito mphamvu, kuchepetsa kuvala kwa nkhungu ya mphete, komanso kuchepetsa ubwino wa tinthu tating'onoting'ono, monga ma pellets sakhala amphamvu mokwanira, maonekedwe ndi omasuka komanso kutalika kwake ndi kosiyana, ndipo mlingo wa ufa ndi wapamwamba.

3.Kutsegula kwa mphete kufa

Kutsegula kwa mphero ya pellet kufa ndi chiŵerengero cha gawo lonse la dzenje lakufa ku gawo lonse la imfa. Nthawi zambiri, kuchuluka kwa kutsegulira kwa kufa kumapangitsa kuti tinthu tambiri tituluke. Pansi pamalingaliro owonetsetsa mphamvu ya kufa, kutsegulira kwa mphete kukhoza kusinthidwa momwe kungathekere.

Kwa zinthu zina zopangira, pansi pa chiŵerengero chololera choponderezedwa, khoma la mphero la pellet ndi lochepa kwambiri, kotero kuti mphamvu ya imfa sikwanira, ndipo chodabwitsa cha kuphulika chidzawonekera pakupanga. Panthawiyi, makulidwe a mphete ya mphete ayenera kuonjezedwa pansi pa malo owonetsetsa kuti kutalika kwa dzenje lakufa.

4.Kufananiza pakati pa mphero ya pellet ndi roller

Ndilo ukadaulo wofunikira kwambiri pakuwongolera magwiridwe antchito a granulation ndikutalikitsa moyo wakufa. Iyenera kukhala ndi mbali 4:

- Mphete yatsopano imafa ndi chodzigudubuza chatsopano, pewani kugwiritsa ntchito mopitilira muyeso.

- Malinga ndi chikhalidwe cha zipangizo, makina mtundu makhalidwe kusankha mitundu yosiyanasiyana ya kuthamanga wodzigudubuza, kuti tikwaniritse bwino extrusion dzuwa pakati kufa ndi mayina.

- Chinsinsi cha kusiyana kwapakati ndikukhazikika ndipo mfundo ndi yakuti: popanda kukhudza mphamvu, yesetsani kumasuka.

- Kuwongolera kufulumira kwa kudyetsa, sinthani malo aatali ndi afupiafupi a kudyetsa scraper kuti muzitha kuyang'anira malo odyetsera, kugawa kosanjikiza.

5.Pellet mphero kufa process process

Mabowo a mphete amafunikira kwambiri potengera zida zopangira ndi kukonza, komanso zitsulo zosapanga dzimbiri, kubowola mfuti zapadera ndi zida zochizira kutentha kwa vacuum zimafunikira kuti apange mphete yapamwamba kwambiri ikafa. Njira yabwino kwambiri yozimitsa vacuum imatha kusintha kwambiri kuuma, kuuma, kukana abrasion, mphamvu ya kutopa komanso kulimba kwachitsulo. Komabe, kutha kutsimikizira kusanjikiza kolimba kwa dzenje lililonse kumafuna luso lapamwamba lokonzekera komanso luso lalitali.

6.The kufa pamwamba roughness wa mkati khoma la bowo kufa

Kuvuta kwa pamwamba ndi chizindikiro chofunikira kwambiri cha mtundu wa mphete. Ambiri, mtengo waung'ono wamkati khoma pamwamba roughness adzasintha khalidwe la koyenera, kuchepetsa kuvala ndi kukulitsa moyo wa mphete kufa, koma mtengo pokonza mphete kufa adzawonjezeka.

Mphete dzenje roughness kumakhudzanso psinjika chiŵerengero ndi kupanga particles, komanso kupanga dzuwa. Pa chiŵerengero chofanana cha mphete kufa, m'munsi mwa roughness mtengo, m'munsi kukana extrusion wa tchipisi nkhuni kapena chakudya, ndi kukhetsa kukhetsa, ndi apamwamba khalidwe pellets opangidwa ndi apamwamba kupanga Mwachangu. Good mphete kufa dzenje processing akhoza kukhala 0.8-1.6 microns, mphete kufa akhakula pafupifupi 0,8 microns, makina olondola pa zinthu disposable, palibe akupera.