The current problems and future development requirements and trends of feed pellet machine Ring Die.

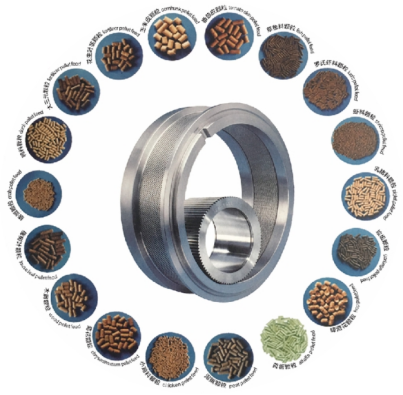

The current problems with the feed pellet machine Ring Die include wear and failure, material selection and manufacturing process issues, usage and maintenance issues, etc. Its development trends include the development of materials science, design theory and technological innovation, and optimization of granulation processes.

Current issues with the feed pellet machine Ring Die:

Wear and failure issues:. During normal operation, friction between the Ring Die and the material can lead to gradual wear and tear. The main causes of failure are abrasive wear and fatigue damage.

Failure phenomena can be divided into three categories: increased discharge aperture, severe unevenness on the inner surface, and decreased structural strength due to increased inner diameter. Factors such as raw material particle size, impurity content, steam addition, gap between the Ring Die and pressure roller, and installation angle of the spreader can all affect the wear rate and Ring Die life.

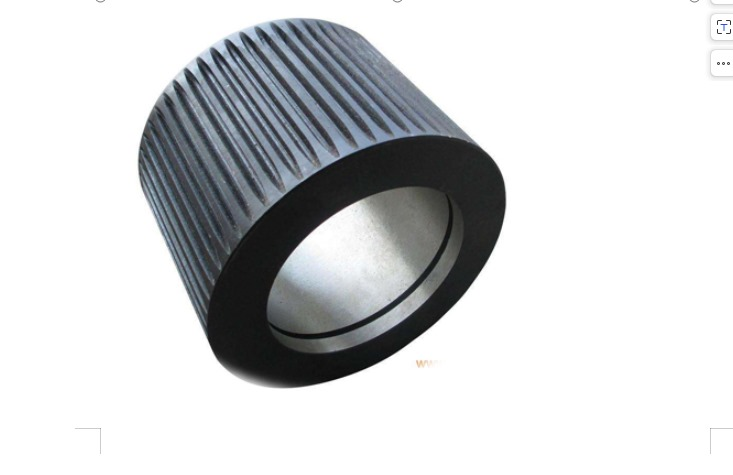

Material selection and manufacturing process issues:. Ring Dies are usually made of alloy steel, carbon steel, or stainless steel. The selection of different materials will directly affect the durability and granulation effect of the Ring Die.

In the manufacturing process, heat treatment and CNC drilling accuracy both affect the performance and service life of the Ring Die.

Usage and maintenance issues:. Insufficient regular maintenance of the pellet machine during use can lead to damage to the Ring Die.

When replacing the Ring Die, it is necessary to ensure compatibility with the pressure roller, otherwise it may cause problems such as eccentricity and uneven wear.

Cost control issue: Granulation energy consumption accounts for 30% -35% of the total energy consumption of the entire workshop, while the cost of Ring Die loss accounts for more than 25% -30% of the decoration cost of the production workshop. Therefore, improving the service life of the Ring Die and reducing the number of replacements are effective methods to reduce costs.

The problem of slow technological updates: Although the Ring Die pellet machine is a key equipment in feed production, its technological updates and innovation speed are relatively slow, especially in some backward production units.

The development trend of feed pellet machine Ring Die:

1.Development of Materials Science:. With the research and application of new materials, such as using more wear-resistant and fatigue resistant materials to manufacture Ring Dies, their working life and granulation efficiency will be greatly improved.

2.Design theory and technological innovation: Continuous research and development will promote innovation in Ring Die design theory, such as optimizing Ring Die structural parameters, motion simulation analysis, etc., thereby further improving its performance and optimizing the granulation process.

3.By optimizing the granulation process parameters, such as adjusting the material moisture content, steam addition amount, pressing temperature, etc., the granulation quality and production efficiency can be improved, and automation and intelligence can be enhanced.

4. Utilize automatic control technology and intelligent systems to monitor and adjust the granulation process in real-time, ensuring that the Ring Die operates under optimal conditions and reducing human operational errors.

4.Environmental and sustainability considerations:. Incorporating environmental protection concepts into the design and production process of Ring Die, such as using renewable materials and reducing energy consumption, is in line with the global trend of environmental protection.