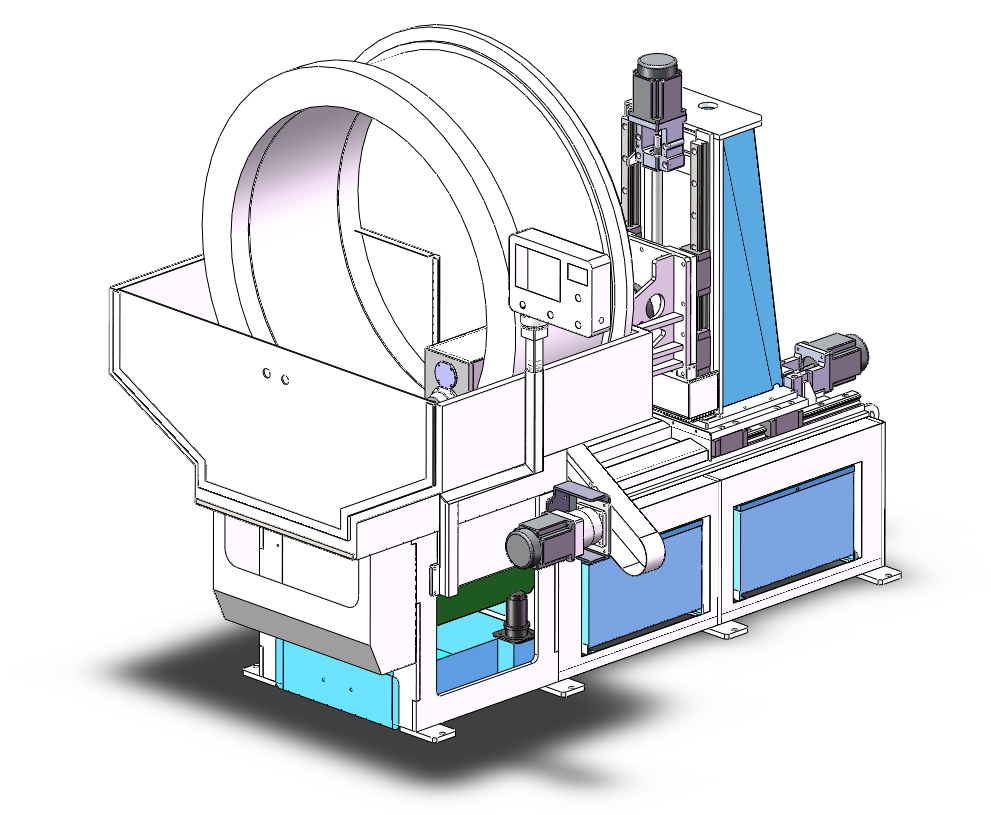

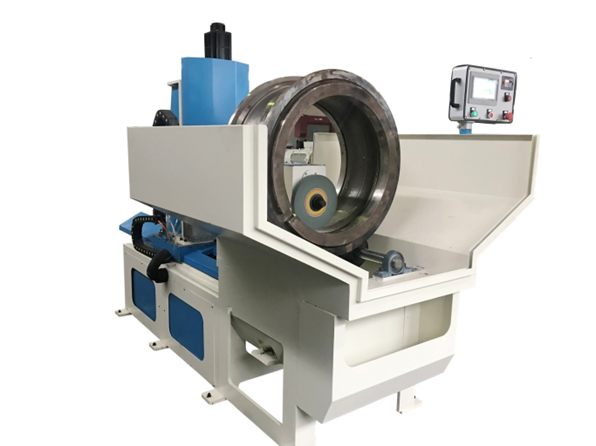

New Arrivals – New Patented Ring Die Repair Machine

Application:

Mainly used for repairing the inner chamfer (flare mouth) of the ring die, rounding the deformed inner working surface, smoothing and clearing the hole (passing feeding).

Advantages than old type

1. Lighter, smaller and more flexible

2. More power saving

3. One working position design, no need to change areas during repairing.

4. Support for multiple languages

5. High cost-effective

6. Suitable for repairing most of ring dies in the market

|

Main Functions |

1. Repair the guide hole of ring die |

| 2. Grinding of the inner working surface of ring die | |

| 3. hole cleaning (passing feeding). | |

|

Available size of ring die |

Inner diameter ≧ 450mm |

| Outer diameter ≦ 1360mm | |

| Working face width ≦ 380 mm, total width ≦500 mm | |

| Diameter scope of processing hole | Φ 1.0 mm≦Chamfering hole diameter≦Φ5.0 mm |

| Φ 2.5 mm≦Cleaning≦ Φ 5.0 mm(≦Φ2.0 are not recommended) | |

| Ring die scope of grinding | Inner diameter ≧ 450mm |

| Ring die circumferential hole splitting method | Supporting wheel friction transmission |

| System language | Standard = Chinese and English Other languages customized |

| Operation mode | Fully automatic operation |

|

Processing efficiency |

Chamfering:1.5s/hole @ Φ3.0 mm hole(not counting the time of splitting holes in the circumference) |

| Cleaning (Passing feeding): depending on the depth of feeding, cleaning speed can be adjusted | |

| Internal grinding: the maximum grinding depth ≦ 0.2 mm each time | |

| Spindle power and speed | 3KW, speed frequency control |

| Power supply | 3 phase 4 Line, provide transformer for overseas voltage |

| Overall Dimensions | Length * width * height: 2280mm *1410mm *1880mm |

| Net Weight | Approx. 1000 kg |