1, Feed Particle Size Determination Method

Feed particle size refers to the thickness of feed raw materials, feed additives, and feed products. At present, the relevant national standard is "Two-layer Sieve Sieving Method for Determination of Feed Grinding Particle Size" (GB/T5917.1-2008). The test procedure is similar to the test method issued by the American Society of Agricultural Engineers. According to the crushing intensity of the feed, the crushing can be divided into two types: coarse crushing and fine crushing. Generally, the particle size is greater than 1000 μm for coarse crushing, and the particle size is less than 600 μm for fine crushing.

2, Feed crushing process

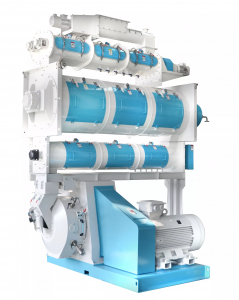

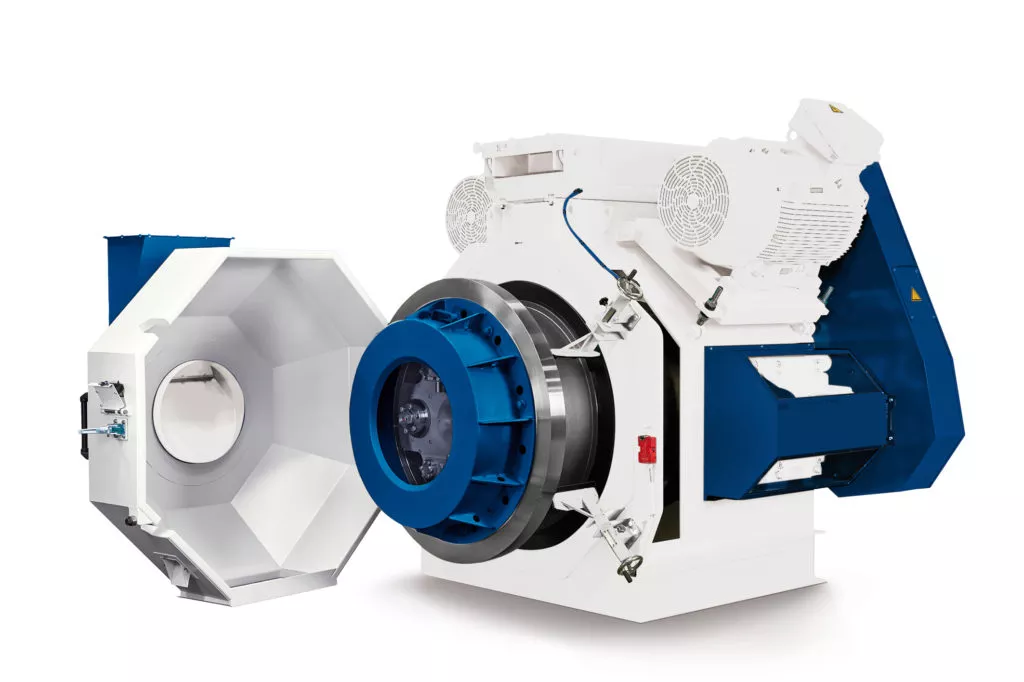

Commonly used feed mills include hammer mills and drum mills. When using, it needs to be selected according to crushing output, power consumption, and feed type. Compared with the hammer mill, the drum mill has more uniform particle size, more difficult operation and higher machine cost. Hammer mills increase grain moisture loss, are noisy, and have less uniform particle size when crushing, but the installation cost may be half that of a drum mill.

Generally , feed mills only install one type of pulverizer, hammer mill or drum mill. Recent studies have shown that multi-step comminution can improve particle size uniformity and reduce power consumption. Multi-step crushing refers to crushing with a hammer mill and then with a drum mill. However, relevant data are scarce, and further research and comparison are needed.

3, Effect of Particle Size on Energy and Nutrient Digestibility of Cereal Feed

Many studies have evaluated the optimal particle size of cereals and the effect of particle size on the digestibility of energy and nutrients. Most of the optimal particle size recommendation literature appeared in the 20th century, and it is believed that feed with an average particle size of 485-600 μm can improve the digestibility of energy and nutrients and promote pig growth.

Numerous studies have shown that reducing the crushed particle size of grains improves energy digestibility. Decreasing the grain size of wheat from 920 μm to 580 μm can increase the ATTD of starch, but has no effect on the ATTD value of GE. The ATTD of GE, DM and CP pigs fed 400μm barley diet were higher than those of 700μm diet. When the particle size of corn decreased from 500μm to 332μm, the degradation rate of phytate phosphorus was also increased. When the grain size of corn decreased from 1200 μm to 400 μm, the ATTD of DM, N, and GE increased by 5% , 7 %, and 7 % respectively , and the type of grinder may have an impact on energy and nutrient digestibility. When the grain size of corn decreased from 865 μm to 339 μm, it increased the ATTD of starch, GE, ME and DE levels, but had no effect on the total intestinal digestibility of P and the SID of AA. When the grain size of corn decreased from 1500μm to 641μm, the ATTD of DM, N and GE could be increased. The ATTD and ME levels of DM, GE in pigs fed 308 μm DDGS were higher than those in 818 μm DDGS pigs, but particle size had no effect on ATTD of N and P. These data show that the ATTD of DM, N, and GE can be improved when the corn grain size is reduced by 500 μm. In general, the particle size of corn or corn DDGS has no effect on phosphorus digestibility. Reducing the crushing particle size of bean feed can also improve energy digestibility. When the particle size of lupine decreased from 1304 μm to 567 μm, ATTD of GE and CP and SID of AA also increased linearly. Similarly, reducing the particle size of red peas can also increase the digestibility of starch and energy. When the particle size of soybean meal decreased from 949 μm to 185 μm, it had no effect on the average SID of energy, essential and non-essential AA, but linearly increased the SID of isoleucine, methionine, phenylalanine and valine. The authors suggested 600 μm soybean meal for optimal AA, energy digestibility. In most experiments, reducing particle size can increase DE and ME levels, which may be related to the improvement of starch digestibility. For diets with low starch content and high fiber content, reducing the particle size of the diet increases DE and ME levels, which may be related to reducing the viscosity of digesta and improving the digestibility of energy substances.

4, Effect of Feed Particle Size on the Pathogenesis of Gastric Ulcer in Pigs

pig stomach is divided into glandular and non-glandular regions. The non-glandular area is a high incidence area of gastric ulcer, because the gastric mucosa in the glandular area has a protective effect. The reduction of feed particle size is one of the causes of gastric ulcer, and the production type, production density, and housing type can also cause gastric ulcer in pigs. For example, the reduction of corn grain size from 1200 μm to 400 μm, and from 865 μm to 339 μm can lead to an increase in the incidence of gastric ulcer in pigs. The incidence of gastric ulcer in pigs fed with pellets of 400 μm corn grain size was higher than that of powder with the same grain size . The use of pellets has resulted in an increased incidence of gastric ulcers in pigs. Assuming that pigs developed gastric ulcer symptoms 7 days after receiving fine pellets , then feeding coarse pellets for 7 days also alleviated gastric ulcer symptoms. Pigs are susceptible to Helicobacter infection after gastric ulceration. Compared with coarse feed and powder feed, the secretion of chloride in the stomach increased when pigs were fed finely crushed diets or pellets. The increase of chloride will also promote the proliferation of Helicobacter, resulting in a decrease in pH in the stomach. Effects of Feed Particle Size on Growth and Production Performance of Pigs

5, Effects of Feed Particle Size on Growth and Production Performance of Pigs

Reducing grain size can increase the action area of digestive enzymes and improve energy and nutrient digestibility. However, this increase in digestibility does not translate into improved growth performance, as pigs will increase their feed intake to compensate for the lack of digestibility and ultimately obtain the energy they need. It is reported in the literature that the optimal particle size of wheat in the rations of weaned piglets and fattening pigs is 600 μm and 1300 μm, respectively.

When the grain size of wheat decreased from 1200μm to 980μm, the feed intake could be increased, but the feed efficiency had no effect. Similarly, when the grain size of wheat decreased from 1300 μm to 600 μm, the feed efficiency of 93-114 kg fattening pigs could be improved, but it had no effect on 67-93 kg fattening pigs. For every 100 μm reduction in corn grain size, the G:F of growing pigs increased by 1.3%. When the corn grain size decreased from 800 μm to 400 μm, the G:F of pigs increased by 7%. Different grains have different particle size reduction effects, such as corn or sorghum with the same particle size and the same particle size reduction range, pigs prefer corn. When the grain size of corn decreased from 1000μm to 400μm, the ADFI of pigs was reduced and G:F was increased. When the grain size of sorghum decreased from 724 μm to 319 μm, G:F of finishing pigs was also increased. However , the growth performance of pigs fed 639 μm or 444 μm soybean meal was similar to that of 965 μm or 1226 μm soybean meal, which may be due to the small addition of soybean meal . Therefore, the benefits brought by the reduction of feed particle size will only be reflected when the feed is added in a large proportion in the diet.

When the grain size of corn decreased from 865 μm to 339 μm or from 1000 μm to 400 μm, and the grain size of sorghum decreased from 724 μm to 319 μm, the carcass slaughter rate of fattening pigs could be improved. The analysis reason may be the decrease of grain size, leading to the decrease of gut weight. However, some studies have found that when the grain size of wheat decreases from 1300 μm to 600 μm, it has no effect on the slaughter rate of fattening pigs. It can be seen that different grains have different effects on particle size reduction, and more research is needed.

There are few studies on the effect of dietary particle size on sow body weight and piglet growth performance. Decreasing the corn grain size from 1200 μm to 400 μm has no effect on the body weight and backfat loss of lactating sows, but reduces the feed intake of sows during lactation and the weight gain of suckling piglets.