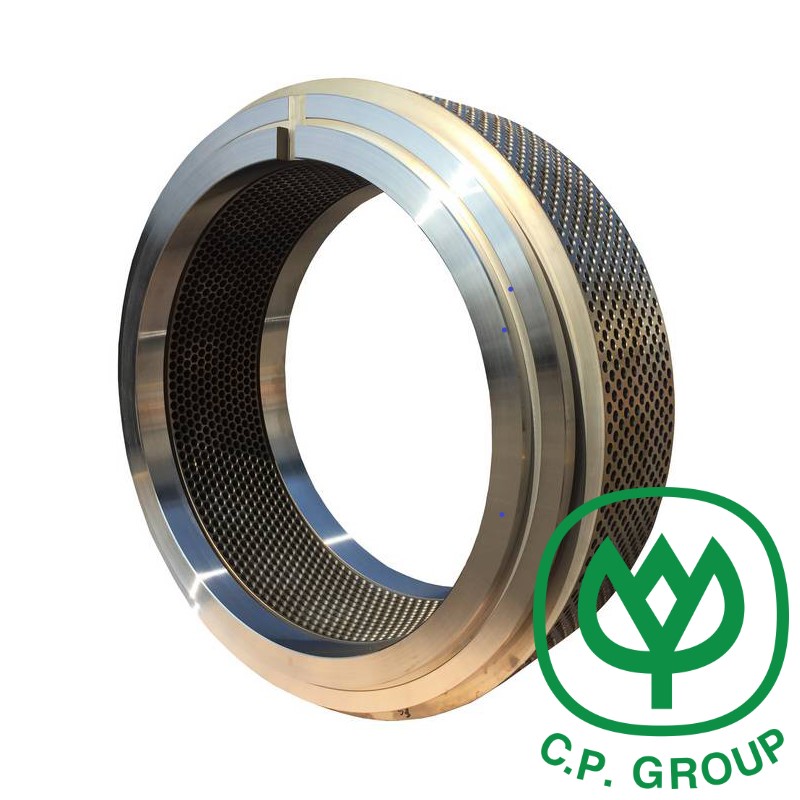

IDAH pellet mill ring mati

- SHH.ZHENGYI

1. Pilih bahan baku berkualitas tinggi, pembuatan baja sekunder, billet degassing;

2.Material ring die: X46Cr13 / 4Cr13 (stainless steel), 42Crmo / 20CrMnTi (baja paduan) utawa bahan khusus liyane;

3. Pengeboran gun lan multi-stasiun sing diimpor, siji-wektu mbentuk bolongan mati, Rampung kualitas dhuwur, produksi feed, katon ayu lan output dhuwur;

4. Pilih kombinasi tungku vakum lan tungku quenching sing terus-terusan kanggo njamin umur layanan sing dawa;

5.Miturut prinsip lan syarat pelanggan kanggo ngrancang rasio kompresi lan kekuatan;

6. Pemeriksaan mikroskopik kanggo njamin kualitas produk;

42Crmo / 20CrMnTi teknologi pangolahan cincin baja paduan:

Cutting → Forging → Normalizing → Roughing → Tempering → Finishing → Drilling (Expanding) Lubang → Carburizing → Grinding → (Kajaba Lapisan Oksidasi) → Pressure Testing → (Fosphorus Passivation) → Coating Antirust Oil → Priksa lan simpen pilihan;

X46Cr13 / 4Cr13 stainless steel ring die teknologi pangolahan:

Cutting → Forging → Roughing → Normalizing → Finishing → Quenching lan tempering → › Finishing → Drilling hole → Nitriding → Polishing → Test tekanan → Coating resistance → Rusty oil → Priksa lan simpen pilihan;

| S/N | Model | Ukuran (mm) OD*ID*jembaré sakabèhé*jembaré pad | Ukuran bolongan mm |

| 1 | IDAH51SA | 660*506*238*152 | 1-12 |

| 2 | IDAH53SA(PM-53SA) | 680*530*258*172 | 1-12 |

| 3 | IDAH53F(PM-53F) | 680*530*278*192 | 1-12 |

| 4 | IDAH635SA | 770*635*266*192 | 1-12 |