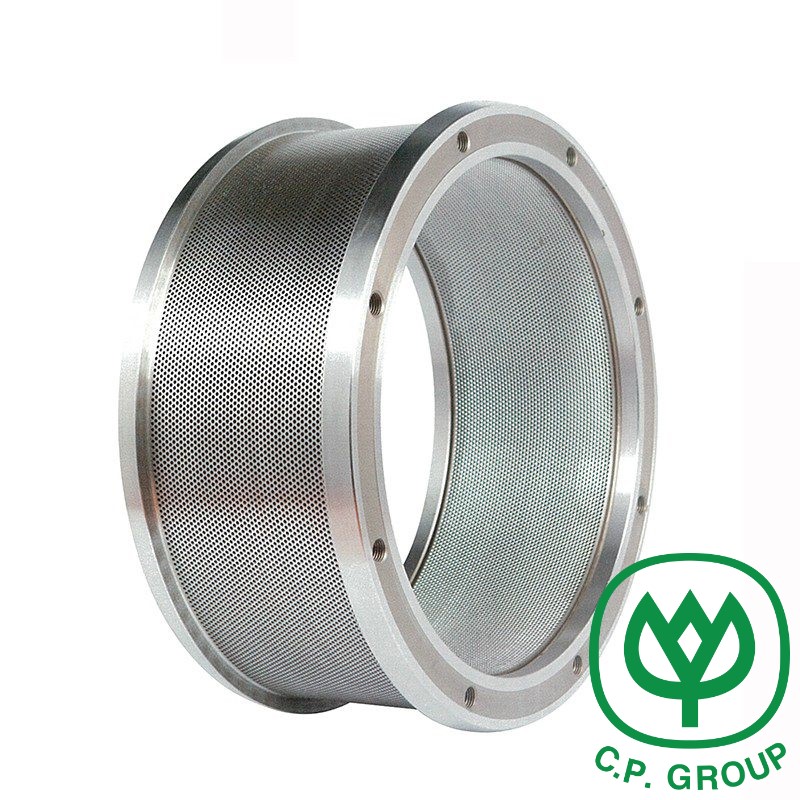

SZLH series pellet zeb nplhaib tuag

- SHH.ZHENGYI

1.Xaiv cov ntaub ntawv zoo raw khoom, theem nrab steelmaking, degassing billet;

2.Ring tuag cov ntaub ntawv: X46Cr13 / 4Cr13 (stainless hlau), 42Crmo / 20CrMnTi (alloy steel) los yog lwm yam khoom siv kev cai;

3.Imported rab phom xyaum thiab ntau lub chaw nres tsheb laum, ib zaug sib sau lub qhov tuag, zoo tiav, ntau lawm ntawm pub, zoo nkauj tsos thiab siab tso zis;

4.Xaiv qhov sib xyaw ua ke ntawm lub tshuab nqus tsev vacuum thiab lub qhov cub tawg tas li kom ntseeg tau tias lub neej ua haujlwm ntev;

5.Raws li lub hauv paus ntsiab lus thiab cov kev xav tau ntawm cov neeg siv khoom tsim compression piv thiab lub zog;

6.Kev kuaj xyuas microscopic kom paub meej cov khoom zoo;

42Crmo / 20CrMnTi alloy steel nplhaib tuag ua tshuab:

Txiav → Forging → Normalizing → Roughing → Tempering → Finishing → Drilling (Expanding) Qhov → Carburizing → Sib tsoo → (tsis suav nrog Oxidation Txheej) → Kev Ntsuas Siab → (Phosphorus Passivation) → Txheej Antirust roj → Tshawb xyuas thiab txuag kev xaiv;

X46Cr13 / 4Cr13 stainless hlau nplhaib tuag ua tshuab:

Txiav → Forging → Roughing → Normalizing → Finishing → quenching thiab tempering → › Nto → Drilling qhov → Nitriding → Polishing → Pressure test → Coating resistance → Rusty oil → check and save options;

| S/N | Qauv | Loj OD * ID * dav dav * pad dav -mm | Qhov loj mm |

| 1 | TXL 320 | 432 * 320 * 130 * 87 hli | 1-12 |

| 2 | TXL 350 | 500 * 350 * 180 * 100 | 1-12 |

| 3 | SWB 400 | 558 * 400 * 200 * 120 | 1-12 |

| 4 | SWB 400D | 558 * 400 * 218 * 138 | 1-12 |

| 5 | TXL 420 | 580 * 420 * 196 * 120 | 1-12 |

| 6 | SWB 420D | 580 * 420 * 214 * 140 | 1-12 |

| 7 | SIB 508 | 660 * 508 * 238 * 155 hli | 1-12 |

| 8 | SWB 508E | 660 * 508 * 284 * 185 | 1-12 |

| 9 | SWB 558 | 774 * 572 * 270 * 170 hli | 1-12 |

| 10 | SWB 578 | 774 * 572 * 300 * 200 hli | 1-12 |

| 11 | SIB 768 | 966 * 761 * 370 * 210 | 1-12 |

Stepped roller plhaub

Cov menyuam plhaub yog ib qho ntawm cov haujlwm tseem ceeb ntawm cov pellet zeb. Siv los ua ntau yam biofuel pellets, tsiaj pub thiab lwm yam pellets. Siv siab hnav-resistant alloy steel (40Cr, 20Crmnti, Gcr15), carburizing tshav kub kho, uniform hardness. Kev pabcuam lub neej yog ntev, thiab muaj ntau hom qauv xws li cov hniav-puab los ntawm-puab, hniav-zoo li thaiv, thiab lub qhov-puab. Qhov nias rau cov menyuam yog ua los ntawm cov ncej sab hauv eccentric thiab lwm qhov chaw nrog qhov ntev, uas yog yooj yim los kho qhov kev ncua deb ntawm lub xovxwm cov menyuam thiab lub nplhaib tuag raws li tus neeg siv cov kev xav tau ntau lawm, thiab nws yooj yim rau quav thiab nruab, thiab nws yog ib qho yooj yim los hloov cov nias lub plhaub.

Cov kev ceev faj:

1. Xaiv qhov tsim nyog tuag qhov compression piv;

2. Kho qhov sib txawv ua haujlwm ntawm lub nplhaib tuag thiab lub siab rau cov menyuam kom nyob nruab nrab ntawm 0.1 thiab 0.3mm (lub siab rau cov menyuam yog tsav los ntawm lub nplhaib tuag tom qab lub granulator tshiab tau tig rau hauv "zoo li tig tab sis tsis tig" lub xeev) ;

3. Lub nplhaib tuag tshiab yuav tsum tau siv nrog cov menyuam lub siab tshiab, thiab cov menyuam lub siab thiab lub nplhaib tuag yuav tsum tau xoob ua ntej thiab tom qab ntawd nruj. Thaum lub kaum ntse ntse tshwm nyob rau ntawm ob sab ntawm lub siab cov menyuam, lub flange ntawm lub siab cov menyuam yuav tsum tau smoothed nrog ib tug tes grinder nyob rau hauv lub sij hawm los pab txhawb ib tug zoo haum ntawm lub siab roller thiab lub nplhaib tuag;

4. Cov khoom siv raw yuav tsum tau ua ntej ntxuav thiab sib nqus sib nqus ua ntej pelletizer kom txo cov hlau nias rau hauv qhov tuag. Thiab xyuas lub qhov tuag tsis tu ncua kom pom tias muaj qhov thaiv. Punch los yog tho tawm lub qhov thaiv pwm hauv lub sijhawm;

5. Yas deformation ntawm phau ntawv qhia lub khob hliav qab ntawm lub nplhaib tuag yuav tsum tau kho. Thaum kho, nws yuav tsum tau muab sau tseg tias qhov qis tshaj ntawm qhov chaw ua hauj lwm sab hauv ntawm lub nplhaib tuag yuav tsum yog 2 hli siab tshaj qhov hauv qab ntawm qhov overtravel zawj, thiab tseem muaj chaw rau kev kho cov eccentric ncej ntawm lub siab roller tom qab kho lwm yam, lub nplhaib tuag yuav tsum tau muab pov tseg;

6. Lub plhaub siab rau cov menyuam yog ua los ntawm cov khoom siv hnav-resistant alloy los ntawm kev ua kub thiab kev kho cua sov. Cov hniav nto daim ntawv ntawm lub siab rau cov menyuam plhaub muaj qee yam cuam tshuam rau kev ua haujlwm ntawm granulation.

Feem ntau siv cov menyuam plhaub hniav profile: hniav profile los ntawm hom, hniav profile tsis yog los ntawm hom, qhov hom.

1. Pass thiab hniav zawj rollers yog siv rau pelletizing tsiaj txhu thiab nqaij qaib cov ntaub ntawv. Qhov kom zoo dua ntawm kev sib tw rollers yog tias lub nplhaib tuag hnav tusyees, tab sis cov coil kev ua haujlwm tsis zoo.

2. Cov hniav zawj cov duab siab cov menyuam muaj cov khoom siv zoo coil kev ua tau zoo thiab feem ntau siv hauv cov khoom noj khoom haus, tab sis hnav lub nplhaib tuag tsis zoo li qub. Cov hniav zawj puab lub siab cov menyuam nrog sealing ntug yog tsuas yog haum rau cov pelletizing ntawm cov ntaub ntawv dej. Xaub rau ob sab.

HELICAL ROLLER Plhaub

Cov menyuam plhaub yog ib qho ntawm cov haujlwm tseem ceeb ntawm cov pellet zeb. Siv los ua ntau yam biofuel pellets, tsiaj pub thiab lwm yam pellets. Siv siab hnav-resistant alloy steel (40Cr, 20Crmnti, Gcr15), carburizing tshav kub kho, uniform hardness. Kev pabcuam lub neej yog ntev, thiab muaj ntau hom qauv xws li cov hniav-puab los ntawm-puab, hniav-zoo li thaiv, thiab lub qhov-puab. Qhov nias rau cov menyuam yog ua los ntawm cov ncej sab hauv eccentric thiab lwm qhov chaw nrog qhov ntev, uas yog yooj yim los kho qhov kev ncua deb ntawm lub xovxwm cov menyuam thiab lub nplhaib tuag raws li tus neeg siv cov kev xav tau ntau lawm, thiab nws yooj yim rau quav thiab nruab, thiab nws yog ib qho yooj yim los hloov cov nias lub plhaub.

Cov kev ceev faj:

1. Xaiv qhov tsim nyog tuag qhov compression piv;

2. Kho qhov sib txawv ua haujlwm ntawm lub nplhaib tuag thiab lub siab rau cov menyuam kom nyob nruab nrab ntawm 0.1 thiab 0.3mm (lub siab rau cov menyuam yog tsav los ntawm lub nplhaib tuag tom qab lub granulator tshiab tau tig rau hauv "zoo li tig tab sis tsis tig" lub xeev) ;

3. Lub nplhaib tuag tshiab yuav tsum tau siv nrog cov menyuam lub siab tshiab, thiab cov menyuam lub siab thiab lub nplhaib tuag yuav tsum tau xoob ua ntej thiab tom qab ntawd nruj. Thaum lub kaum ntse ntse tshwm nyob rau ntawm ob sab ntawm lub siab cov menyuam, lub flange ntawm lub siab cov menyuam yuav tsum tau smoothed nrog ib tug tes grinder nyob rau hauv lub sij hawm los pab txhawb ib tug zoo haum ntawm lub siab roller thiab lub nplhaib tuag;

4. Cov khoom siv raw yuav tsum tau ua ntej ntxuav thiab sib nqus sib nqus ua ntej pelletizer kom txo cov hlau nias rau hauv qhov tuag. Thiab xyuas lub qhov tuag tsis tu ncua kom pom tias muaj qhov thaiv. Punch los yog tho tawm lub qhov thaiv pwm hauv lub sijhawm;

5. Yas deformation ntawm phau ntawv qhia lub khob hliav qab ntawm lub nplhaib tuag yuav tsum tau kho. Thaum kho, nws yuav tsum tau muab sau tseg tias qhov qis tshaj ntawm qhov chaw ua hauj lwm sab hauv ntawm lub nplhaib tuag yuav tsum yog 2 hli siab tshaj qhov hauv qab ntawm qhov overtravel zawj, thiab tseem muaj chaw rau kev kho cov eccentric ncej ntawm lub siab roller tom qab kho lwm yam, lub nplhaib tuag yuav tsum tau muab pov tseg;

6. Lub plhaub siab rau cov menyuam yog ua los ntawm cov khoom siv hnav-resistant alloy los ntawm kev ua kub thiab kev kho cua sov. Cov hniav nto daim ntawv ntawm lub siab rau cov menyuam plhaub muaj qee yam cuam tshuam rau kev ua haujlwm ntawm granulation.

Feem ntau siv cov menyuam plhaub hniav profile: hniav profile los ntawm hom, hniav profile tsis yog los ntawm hom, qhov hom.

1. Pass thiab hniav zawj rollers yog siv rau pelletizing tsiaj txhu thiab nqaij qaib cov ntaub ntawv. Qhov kom zoo dua ntawm kev sib tw rollers yog tias lub nplhaib tuag hnav tusyees, tab sis cov coil kev ua haujlwm tsis zoo.

2. Cov hniav zawj cov duab siab cov menyuam muaj cov khoom siv zoo coil kev ua tau zoo thiab feem ntau siv hauv cov khoom noj khoom haus, tab sis hnav lub nplhaib tuag tsis zoo li qub. Cov hniav zawj puab lub siab cov menyuam nrog sealing ntug yog tsuas yog haum rau cov pelletizing ntawm cov ntaub ntawv dej. Xaub rau ob sab.