Chaw tsim tshuaj paus ntawm PTN Series Nplhaib Tuag rau Pellet zeb spare qhov chaw

- SHH.ZHENGYI

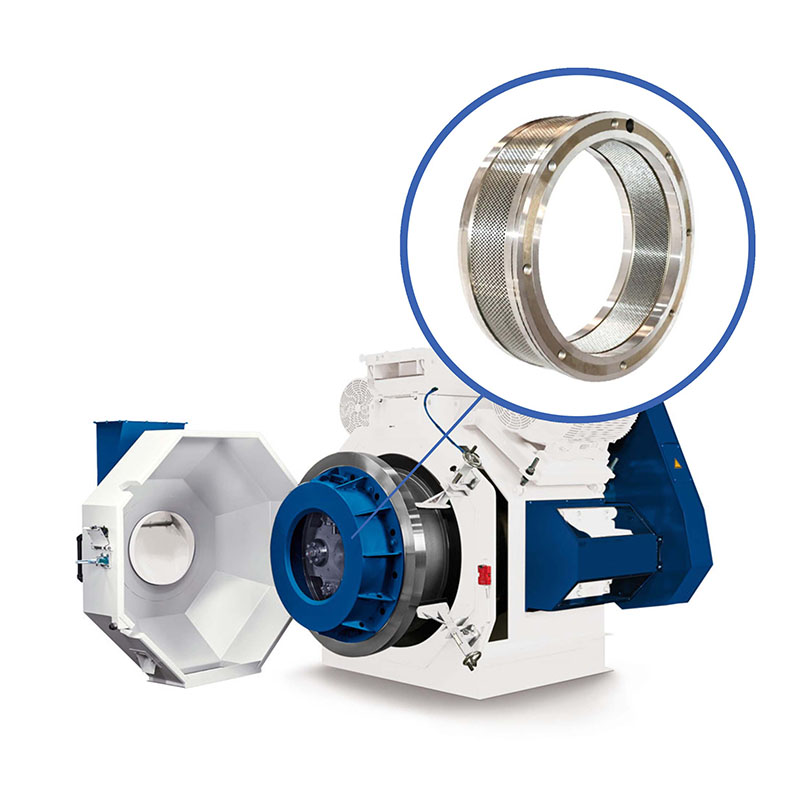

● PTN series nplhaib tuag

PTN pellet zeb series nplhaib tuag yog ua los ntawm cov hlau zoo hlau lossis cov hlau tsis muaj chromium (German standard X46cr13). Nws yog ua tiav los ntawm forging, txiav, drilling, kho cua sov thiab lwm yam txheej txheem. Los ntawm kev tswj hwm nruj thiab kev ua haujlwm zoo, lub hardness, tuag qhov uniformity thiab tuag qhov tiav ntawm lub nplhaib ntau lawm tau mus txog qhov zoo heev.

Parameter

| S/N | Qauv | LojOD * ID * dav dav * pad dav -mm | Qhov lojmm |

| 1 | PTN450 | 560 * 450 * 180 * 106 | 1-12 |

| 2 | PTN 580 | 680 * 580 * 216 * 140 | 1-12 |

| 3 | PTN 650 | 791 * 650 * 245 * 175 hli | 1-12 |

Kev tshuaj xyuas qhov xwm txheej txawv txav thiab pom zoo txhim kho

Yog vim li cas Analysis rau Broken (ib txwm tshwm sim nyob rau hauv

nruam casting ntawm cov lag luam me)

1. Tuag tawg los ntawm lub log sib txuam nto

2. Tuag tawg los ntawm hnav thiab deformation ntawm lub nplhaib tuag hauv ob sab phlu.

3. Tuag tawg los ntawm kev ceeb toom ntawm kev tsav tsheb.

4. Indentation impressed nyob rau saum npoo ntawm cov tuag rau lub weakening nyhuv ntawm lub de-ironing ntaus ntawv, thiab ces ua rau tuag tawg.

5. Qhov qhib me me ntawm qhov tuag thiab cov menyuam compression.

6. Tuag tawg los ntawm me me compression piv, me me txoj kab uas hla ntses pub tuag yam tsis muaj siab-relief vent.

| Tsis muaj. | Qhov tshwm sim | Yog vim li cas | Kev daws teeb meem |

| 1 | Particle khoov, nrog tawg |

| |

| 2 | Nrog transversal tawg |

| |

| 3 | Kab nrib pleb |

| |

| 4 | Radiative tawg | Cov khoom loj muaj nyob (ib nrab ntawm oorn lossis tag nrho pob kws sab laug) | Tswj lub fineness ntawm raw cov ntaub ntawv, nce sib tsoo evenness. |

| 5 | Deg unevenness |

| |

| 6. | Whisker zoo li pellet | Ntau lub zog ntau dhau thiab siab dhau lawm, pellet tawg thaum sab laug tuag. | 1. Txo cov cua siab, siv cov cua kub qis (15 - 20psi) rau kev txias. 2. Txheeb xyuas qhov chaw ntawm qhov txo valve. |