QHOV 1: Kev tshuaj xyuas ua ntej kev teeb tsa

1. Nplhaib tuag Inspection Ua ntej Installation

Seb qhov chaw ua haujlwm yog qhov sib npaug.

Seb lub zawj yog hnav, thiab seb lub qhov threaded puas lawm.

Seb Dia qhov thiab Compression ratio yog lawm

Txawm hais tias muaj cov hniav los yog hnav cov cim ntawm lub hoop thiab tapered nto, raws li qhia hauv daim duab 1 thiab 2.

2. Kev tshuaj xyuas cov menyuam ua ntej kev teeb tsa

Txawm hais tias cov khoom sib hloov yog qhov qub

Seb lub ntug ntawm cov menyuam hnav

Seb tus hniav zoo li cas lawm

3. Txheeb xyuas qhov hnav ntawm lub hoop, thiab hloov lub hoop tsis zoo rau lub sijhawm

4. Txheeb xyuas qhov hnav ntawm qhov chaw mounting ntawm lub npoo tsav, thiab hloov lub voj voog tsav tsis tau raws sijhawm

5. Tshawb xyuas thiab kho lub kaum sab xis ntawm lub scraper kom tsis txhob sib kis ntawm cov khoom sib xws

6. Seb lub installation qhov ntawm lub khob hliav qab yog puas los yog tsis

PART 2: YUAV TSUM TAU TXAIS RING DIE INSTALLATION

1. Tighten tag nrho cov txiv ntseej thiab bolts symmetrically rau qhov xav tau torque

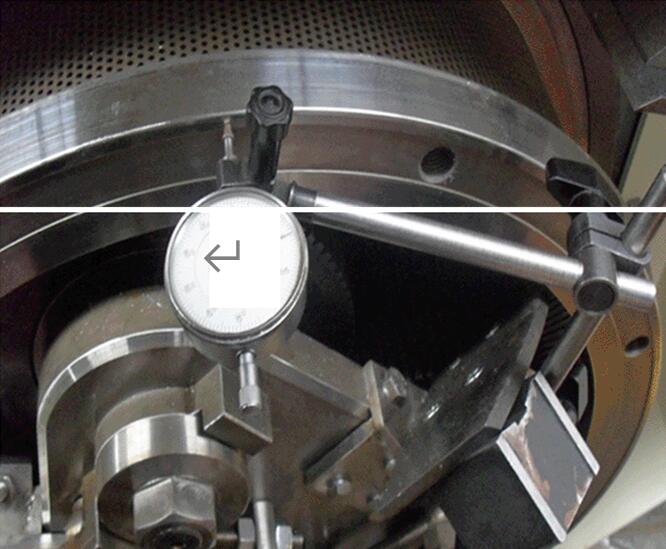

-SZ LH SSOX 1 70 (600 qauv) ua piv txwv, lub nplhaib tuag locking torque yog 30 0 N. m, Fengshang-SZ LH535 X1 90 granulator tuav lub thawv bolt zawm torque 470N.m), torque ciaj ntswj raws li qhia hauv daim duab 3 ; Thaum lub khob lub nplhaib tuag raug teeb tsa, lub ntsej muag kawg ntawm lub nplhaib tuag yuav tsum khaws cia li ntawm 0.20 hli, raws li pom hauv daim duab 4.

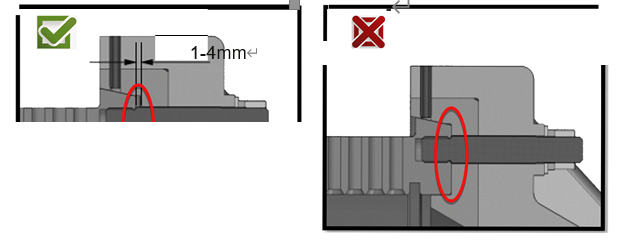

2. Thaum lub cone nplhaib tuag yog ntsia, qhov clearance nruab nrab ntawm lub kawg lub ntsej muag ntawm lub nplhaib tuag thiab lub ntsej muag kawg ntawm lub log flange yog 1-4 hli, raws li qhia nyob rau hauv daim duab 5, yog hais tias lub clearance yog heev me me los yog tsis muaj. clearance, lub ntug tsav yuav tsum tau hloov, txwv tsis pub lub fastening bolts yuav tawg los yog lub nplhaib tuag yuav tawg.

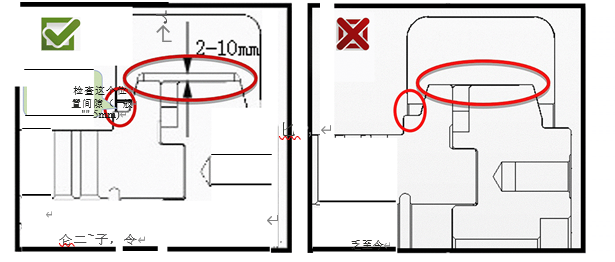

3. Thaum txhim kho lub nplhaib tuag, xauv tag nrho cov txiv ntseej thiab bolts symmetrically raws li qhov xav tau torque, thiab xyuas kom meej tias qhov sib txawv ntawm txhua lub thawv tuav yog sib npaug thaum lub sijhawm kaw. Siv lub ntsuas ntsuas ntsuas qhov sib txawv ntawm sab hauv qab ntawm lub thawv tuav thiab sab nrauv ntawm lub nplhaib tuag tuav lub thawv (feem ntau 2-10mm). Raws li pom hauv daim duab 6, yog tias qhov sib txawv me dhau los yog tsis muaj qhov sib txawv, lub thawv tuav yuav tsum tau hloov.

4. Qhov sib txawv ntawm qhov tuag yuav tsum nyob nruab nrab ntawm 0.1-0.3 hli, thiab kev hloov kho tuaj yeem ua tiav los ntawm kev tshuaj xyuas qhov muag. Thaum lub nplhaib tuag tig, nws yog qhov zoo dua tias lub dov tsis tig. Thaum siv lub nplhaib tuag tshiab, tshwj xeeb tshaj yog thaum siv lub nplhaib tuag nrog lub qhov tuag me me, qhov tuag dov qhov sib txawv feem ntau yog nce ntxiv kom ua tiav lub sijhawm khiav ntawm qhov tuag dov thiab zam qhov tshwm sim calendering ntawm lub nplhaib tuag tswb lub qhov ncauj.

5. Tom qab lub nplhaib tuag raug ntsia, xyuas seb cov menyuam puas yog ntug-nias

PART 3: RING DIE STORAGE THIAB MAINTENANCE

1. Lub nplhaib tuag yuav tsum tau muab cia rau hauv qhov chaw qhuav thiab huv si thiab cim nrog cov lus qhia tshwj xeeb.

2. Rau lub nplhaib tuag uas tsis siv rau lub sijhawm ntev, nws raug nquahu kom coated nrog ib txheej ntawm cov roj los tiv thaiv xeb.

3. Yog hais tias qhov tuag qhov ntawm lub nplhaib tuag yog thaiv los ntawm cov khoom, thov siv cov txheej txheem ntawm cov roj immersion los yog ua noj kom soften cov khoom, thiab ces re-granulate.

4. Thaum lub nplhaib tuag yog khaws cia rau ntau tshaj 6 lub hlis, cov roj hauv tsev yuav tsum tau ntim.

5. Tom qab lub nplhaib tuag tau siv rau ib lub sijhawm, tsis tu ncua xyuas seb puas muaj cov kab mob hauv zos ntawm lub puab nto ntawm lub nplhaib tuag, thiab xyuas seb lub qhov tuag qhov taw qhia qhov chaw nres nkoj yog hauv av, kaw lossis tig sab hauv, raws li qhia. nyob rau hauv daim duab 8. Yog tias pom, lub nplhaib tuag yog kho kom ntev lub neej kev pab cuam, raws li qhia hauv daim duab 9. Thaum kho, nws yuav tsum tau muab sau tseg tias qhov qis tshaj ntawm cov haujlwm sab hauv ntawm lub nplhaib. tuag yuav tsum yog 2 hli saum toj no hauv qab ntawm qhov overtravel groove, thiab tseem muaj kev hloov kho rau lub dov eccentric ncej tom qab kho.