Taurin barbashi ɗaya ne daga cikin ingantattun alamomin da kowane kamfani na ciyarwa ke ba da kulawa sosai. A cikin ciyarwar dabbobi da kaji, tsananin taurin zai haifar da rashin jin daɗi, rage cin abinci, har ma yana haifar da ciwon baki a cikin alade masu shayarwa. Koyaya, idan taurin ya yi ƙasa, abun cikin foda zai ragu. Haɓakawa, musamman ƙarancin taurin kayan pellet shima zai haifar da ingantattun abubuwa marasa kyau kamar rarraba abinci. Don haka, kamfanoni dole ne su tabbatar da cewa taurin ciyarwar ta cika ka'idojin inganci. Baya ga daidaita tsarin ciyarwa, suna kuma mai da hankali kan matakai daban-daban na samarwa da sarrafawa, wanda kuma zai yi tasiri mai mahimmanci akan taurin abincin pellet.

1) Dalilin da ke taka muhimmiyar rawa a cikin taurin barbashi a cikin aikin nika shine girman nau'in kayan nika. Gabaɗaya magana, mafi girman girman ƙwayar niƙa na albarkatun ƙasa, sauƙin shine sitaci don gelatinize yayin aiwatar da kwandishan, kuma mafi ƙarfi tasirin haɗin gwiwa a cikin pellets. Mafi ƙarancin karyewa, mafi girman taurin. Sabili da haka, a cikin samarwa na ainihi, girman ƙwayar ƙwayar cuta yana buƙatar daidaitawa daidai gwargwadon aikin samarwa na dabbobi daban-daban da girman zobe ya mutu buɗewar.

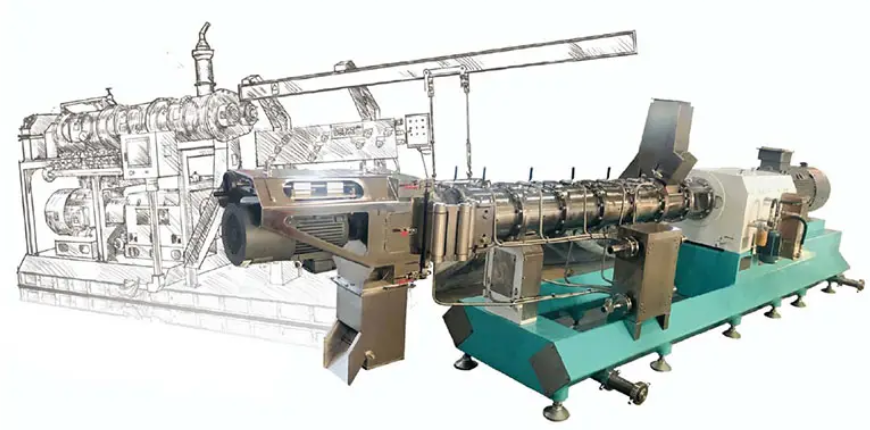

2) Ta hanyar daɗaɗɗen daɗaɗɗen kayan abinci, ana iya cire gubar da ke cikin albarkatun ƙasa, ana iya kashe ƙwayoyin cuta, ana iya kawar da abubuwa masu cutarwa, ana iya cire sunadaran da ke cikin albarkatun ƙasa, kuma za a iya fitar da sitaci gabaɗaya. A halin yanzu, an fi amfani da kayan da aka ɗora a cikin samar da abincin alade mai ƙima da abinci na musamman na ruwa. Don samfuran ruwa na musamman, bayan an busa albarkatun ƙasa, matakin sitaci gelatinization yana ƙaruwa kuma taurin ƙwayoyin da aka kafa shima yana ƙaruwa, wanda ke da fa'ida don haɓaka kwanciyar hankali na barbashi a cikin ruwa. Don ciyar da alade mai tsotsa, ana buƙatar ɓangarorin su kasance masu ƙyalƙyali kuma ba su da wuyar gaske, wanda ke da amfani ga ciyar da alade masu shayarwa. Duk da haka, saboda yawan adadin sitaci gelatinization a cikin kumbura na tsotsa pellets alade, taurin pellets ɗin yana da girma.

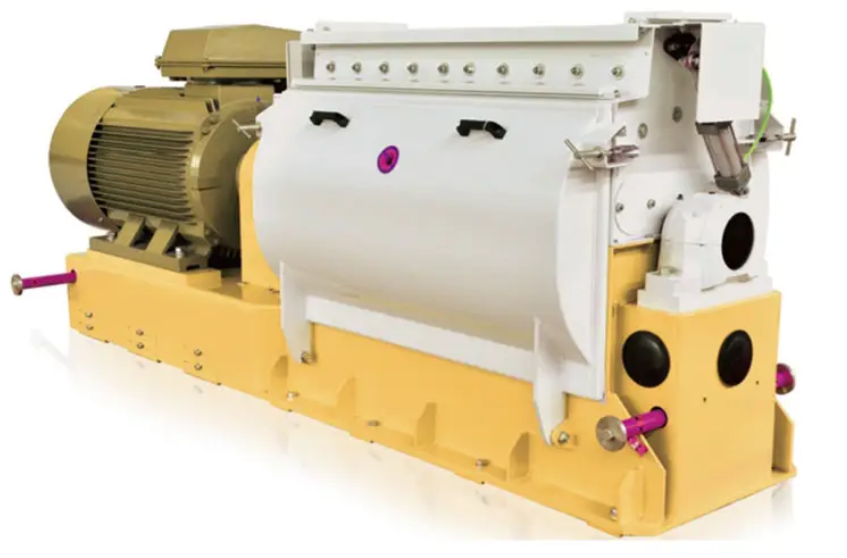

3) A hadawa da albarkatun kasa iya inganta uniformity na daban-daban barbashi size aka gyara, wanda yake da amfani ga kiyaye barbashi taurin m m da inganta samfurin quality. A cikin samar da abincin pellet mai wuya, ƙara 1% zuwa 2% danshi a cikin mahaɗin zai taimaka inganta kwanciyar hankali da taurin abincin pellet. Duk da haka, yana da mahimmanci a yi la'akari da mummunan tasirin karuwar danshi akan bushewa da sanyaya pellets. Hakanan ba shi da amfani ga ajiyar samfur. A cikin samar da jikakken abincin pellet, ana iya ƙara danshi har zuwa 20% zuwa 30% a cikin foda. Yana da sauƙi don ƙara kusan 10% danshi yayin tsarin haɗuwa fiye da lokacin tsarin yanayin. Pellets da aka kafa daga kayan daɗaɗɗen daɗaɗɗa suna da ƙarancin tauri, taushi da kyakkyawar jin daɗi. Manyan masana'antun kiwo na iya amfani da wannan jikakken abincin pellet. Kwayoyin rigar gabaɗaya ba su da sauƙin adanawa kuma ana buƙatar gabaɗaya a ciyar da su nan da nan bayan samarwa. Ƙara mai a lokacin aikin hadawa shine tsarin ƙara mai da aka saba amfani dashi a cikin taron samar da abinci. Ƙara 1% zuwa 2% na man shafawa yana da ɗan tasiri akan rage taurin barbashi, yayin da ƙara 3% zuwa 4% na mai zai iya rage taurin barbashi.

4) Tushen kwandishan shine maɓalli mai mahimmanci a cikin sarrafa abinci na pellet, kuma tasirin kwandishan yana shafar tsarin ciki kai tsaye da ingancin bayyanar pellets. Ingancin tururi da lokacin sanyaya abubuwa ne masu mahimmanci guda biyu waɗanda ke shafar tasirin kwandishan. Babban ingancin bushewa da cikakken tururi na iya samar da ƙarin zafi don ƙara yawan zafin jiki na kayan kuma gelatinize sitaci. Tsawon lokacin sanyi, mafi girman matakin sitaci gelatinization. Mafi girma da darajar, da denser da barbashi tsarin bayan forming, da mafi alhẽri da kwanciyar hankali, kuma mafi girma da taurin. Don ciyarwar kifi, ana amfani da jaket mai nau'i-nau'i ko nau'i-nau'i da yawa don daidaitawa don ƙara yawan zafin jiki da kuma tsawaita lokacin sanyi. Ya fi dacewa don inganta zaman lafiyar barbashin ciyarwar kifi a cikin ruwa, kuma taurin barbashi shima yana ƙaruwa daidai da haka.

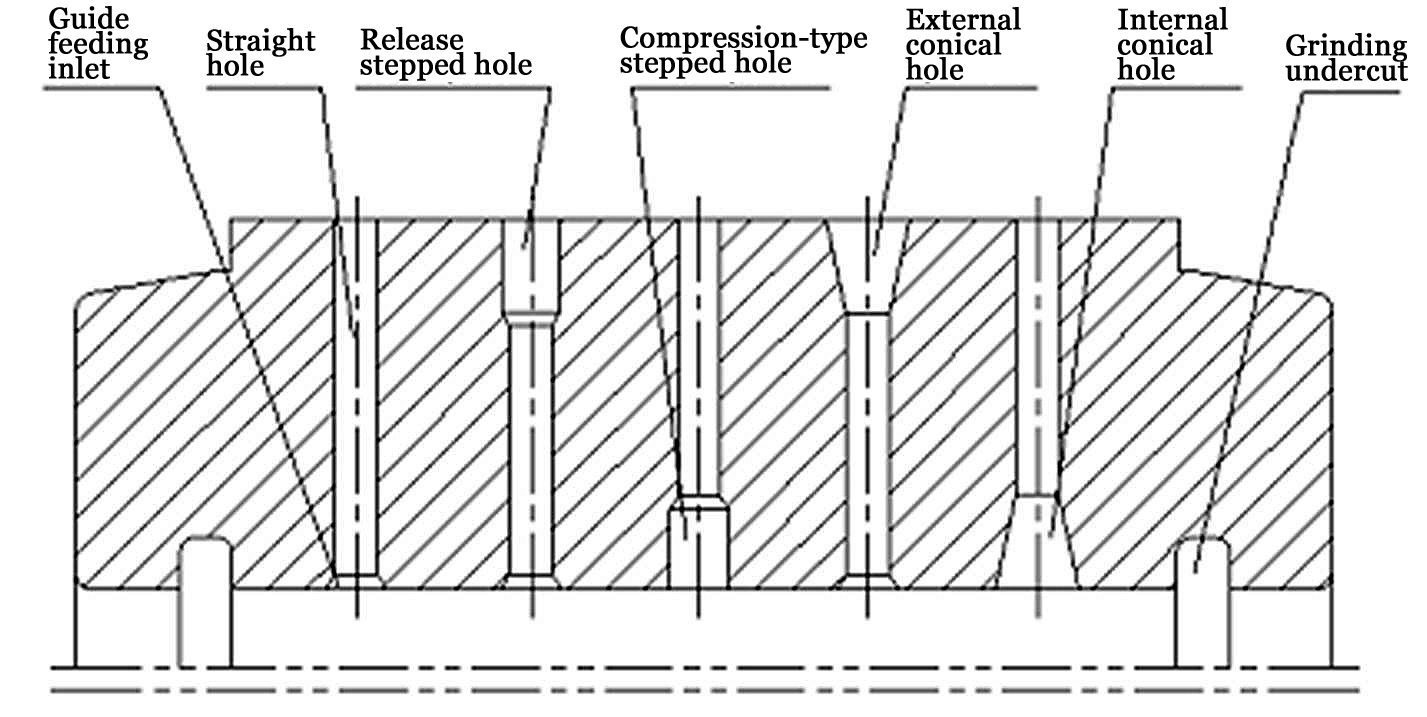

5) A yayin aiwatar da granulation, sigogi na fasaha kamar buɗaɗɗen buɗaɗɗen da matsawa na zobe mutu zai kuma shafi taurin barbashi. Tauri na barbashi da aka kafa ta zoben gyaggyarawa tare da buɗaɗɗe iri ɗaya amma nau'ikan matsawa daban-daban za su ƙaru sosai tare da haɓaka ƙimar matsawa. . Zaɓin mutuwar zobe tare da matsi mai dacewa zai iya samar da barbashi tare da taurin da ya dace. A lokaci guda kuma, tsayin ɓangarorin kuma yana da tasiri mai mahimmanci akan ƙarfin ɗaukar nauyin ƙwayoyin. Don barbashi na diamita ɗaya, idan barbashi ba su da lahani, tsayin barbashi, mafi girman taurin da aka auna. Saboda haka, daidaitawa matsayi na abun yanka don kula da wani dace barbashi tsawon zai iya ci gaba da taurin barbashi m m. Diamita na barbashi da siffar giciye kuma suna da wani tasiri akan taurin barbashi. Bugu da ƙari, kayan aiki na zobe ya mutu kuma yana da wani tasiri akan ingancin bayyanar da taurin pellets. Akwai bambance-bambance a bayyane tsakanin abincin pellet wanda talakawan zoben karfe ya mutu da zoben bakin karfe ya mutu.

Don tsawaita lokacin ajiyar kayan abinci da tabbatar da ingancin samfur a cikin wani ƙayyadadden lokaci, ana buƙatar bushewa da sanyaya aiki na abubuwan abinci.