Mafi kyawun masana'anta na Rufe hakori Roller Shell

- SHH.ZHENGYI

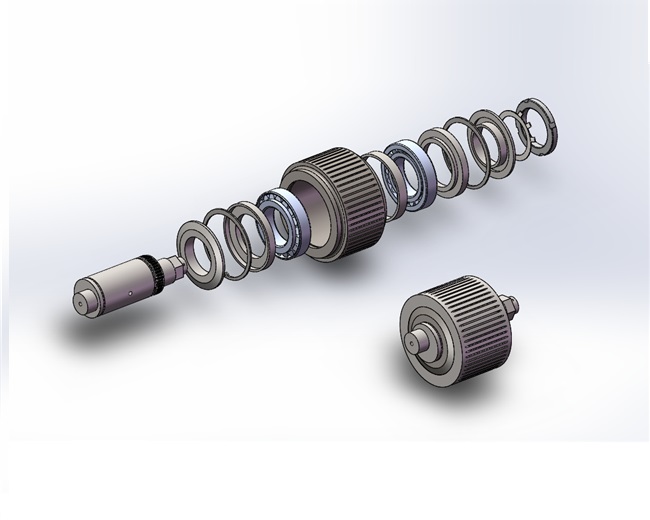

Harsashin nadi yana ɗaya daga cikin manyan sassan aiki na injin pellet. Ana amfani da su don sarrafa nau'ikan pellets na biofuel daban-daban, abincin dabbobi da sauran pellets. Yin amfani da ƙarfe mai ƙarfi mai jure lalacewa (40Cr, 20Crmnti, Gcr15), maganin zafi na carburizing, taurin uniform. Rayuwar sabis tana da tsawo, kuma akwai nau'ikan nau'ikan halitta kamar su-dimbin hali ne ta hanyar dimbin siffa, toshe haƙoran haƙori, da kuma mai kama da rami. An yi ɓangaren abin nadi na latsawa na ciki eccentric shaft da sauran sassa tare da madaidaicin ma'auni, wanda ya dace don daidaita nisa tsakanin latsa abin nadi da zobe ya mutu bisa ga buƙatun samar da mai amfani, kuma yana da sauƙin ninkawa da shigarwa, kuma shi yana da sauƙin maye gurbin harsashi mai latsawa.

Harsashin nadi yana ɗaya daga cikin manyan sassan aiki na injin pellet. Ana amfani da su don sarrafa nau'ikan pellets na biofuel daban-daban, abincin dabbobi da sauran pellets. Yin amfani da ƙarfe mai ƙarfi mai jure lalacewa (40Cr, 20Crmnti, Gcr15), maganin zafi na carburizing, taurin uniform. Rayuwar sabis tana da tsawo, kuma akwai nau'ikan nau'ikan halitta kamar su-dimbin hali ne ta hanyar dimbin siffa, toshe haƙoran haƙori, da kuma mai kama da rami. An yi ɓangaren abin nadi na latsawa na ciki eccentric shaft da sauran sassa tare da madaidaicin ma'auni, wanda ya dace don daidaita nisa tsakanin latsa abin nadi da zobe ya mutu bisa ga buƙatun samar da mai amfani, kuma yana da sauƙin ninkawa da shigarwa, kuma shi yana da sauƙin maye gurbin harsashi mai latsawa.

Matakan kariya

1.Daidai zaɓi madaidaicin matsi ramin mutun da ya dace.

2.Daidai daidaita tazarar aiki tsakanin mutuwar zobe da abin nadi na matsa lamba ya kasance tsakanin 0.1 da 0.3mm (nadi mai matsa lamba yana motsa zobe ya mutu bayan an kunna sabon granulator a cikin yanayin "kamar juyawa amma ba jujjuya ba").

3.Dole ne a yi amfani da sabon mutuwar zobe tare da sabon abin nadi na matsa lamba, kuma abin nadi da matsi da zoben dole ne a kwance kafin sannan kuma a danne su. Lokacin da kusurwoyi masu kaifi suka bayyana a ɓangarorin biyu na abin nadi na matsa lamba, ya kamata a daidaita flange na abin nadi mai matsa lamba tare da injin niƙa a cikin lokaci don sauƙaƙe dacewa mai kyau tsakanin abin nadi da zobe ya mutu.

4.Dole ne a sha ɗanyen kayan aikin tsaftacewa na farko da rabuwar maganadisu kafin pelletizer don rage matsi da baƙin ƙarfe a cikin ramin mutuwa. Kuma a rika duba ramin mutuwa akai-akai don ganin ko akwai wani toshewa. Fitar ko fitar da rami da aka toshe cikin lokaci.

5.Ya kamata a gyara nakasar filastik na ramin mazugi na mazugi na zoben mutun. Lokacin gyara, ya kamata a lura cewa mafi ƙasƙanci na aikin ciki na zobe ya mutu ya kamata ya zama 2mm mafi girma fiye da kasan tsagi na overtravel, kuma har yanzu akwai dakin don daidaita madaidaicin madaidaicin abin nadi bayan gyara In ba haka ba. zobe mutu ya kamata a soke.

6.An yi harsashin abin nadi na matsin lamba da kayan gami da ke jure lalacewa ta hanyar sarrafa gwal da maganin zafi. Siffar saman haƙori na harsashi mai matsa lamba yana da wani tasiri akan aikin granulation.

Bayanan martabar haƙoran haƙoran da aka saba amfani da su: bayanin martabar haƙori ta nau'in, bayanin martabar haƙori ba ta nau'in ba, nau'in rami.

1.Ana amfani da rollers ɗin wucewa da tsagi na haƙori don kashe dabbobi da kayan kiwon kaji. Amfanin wucewar rollers shine cewa zoben mutun yana sawa daidai, amma aikin nada ba shi da kyau.

2.Siffar tsagi na haƙori na matsa lamba yana da kyakkyawan aikin kayan coil kuma ana amfani da shi sosai a masana'antar abinci, amma lalacewa na zobe ba iri ɗaya bane. Siffar tsagi haƙori matsa lamba abin nadi tare da hatimi baki ya fi dacewa da pelletizing na ruwa kayan. Zamewa a bangarorin biyu.